A circuit breaker is a type of switch designed to interrupt the flow of abnormal, or fault current. When a high current flows through a circuit, the breaker acts as a mechanical safety device that automatically cuts off the power supply, protecting the system from damage. Its main role is to safely open or close electrical circuits and prevent mishaps due to overloads or faults.

In simple terms, what is a circuit breaker? It’s an automatic safety device that stops current flow instantly during overcurrent, ground faults, or short circuits.

Often referred to as a safety switch, a circuit breaker trips automatically when protective relays detect a fault. Also known as an electrical circuit breaker or ckt breaker, it plays a critical role in residential, commercial, and industrial systems.

Wondering what circuit breakers are used for? They help ensure:

- Electrical safety

- System reliability

- Quick restoration after faults

Working Principle of Circuit Breaker

A circuit breaker has fixed and moving contacts. These contacts touch each other and carry current when the circuit is closed under normal conditions. The contacts engage each other under the pressure of a spring when the circuit breaker is closed.

Under normal operating conditions, the circuit breaker’s arms can be opened or closed to switch and maintain the system. To interrupt the circuit, a trigger mechanism or relay signal initiates a release of stored mechanical energy.

Whenever a fault occurs in the system, the breaker’s trip coil gets energized, causing the moving contacts to separate, thus opening the circuit.

How Does a Circuit Breaker Clear the Fault?

- Detection of Fault: The protection relay detects faults, such as overloads or short circuits.

- Activation of Mechanism: The protection relay issues a trip command to the circuit breaker, and the breaker initiates a mechanism that releases stored potential energy.

- Separation of Contacts: This energy separates the two main contacts of the circuit breaker: a fixed contact and a moving contact.

- Arc Formation: The separation of contacts produces a high-energy plasma called an arc.

- Arc Quenching: The breaker uses various methods to extinguish the arc, such as cooling, compressing, or replacing the ionized medium with fresh gas.

- Current Interruption: The process involves interrupting the flow of current, which stops any damage caused by the fault condition

- Resetting: After the fault is resolved, the circuit breaker can be reset manually or automatically, allowing the current to flow again.

- Re-establishment of Contacts: Resetting the circuit breaker reconnects the fixed and moving contacts, allowing current to flow through the circuit again.

This mechanism makes circuit breakers more advanced and reliable than fuses.

Types of Circuit Breaker

Circuit breakers are classified based on their rated voltages. Those rated below 1000V are low-voltage circuit breakers, while those rated above 1000V are high-voltage circuit breakers.

The different types of circuit breakers can be classified based on the medium used for arc extinction.

- Oil Circuit Breaker

- Bulk Oil Circuit Breaker

- Minimum Oil Circuit Breaker

- Air Circuit Breaker

- Sulphur Hexafluoride (SF6) Circuit Breaker

- Vacuum Circuit Breaker

All high-voltage circuit breakers fall into two broad categories: oil circuit breakers and oil-less circuit breakers.

Oil Circuit Breaker

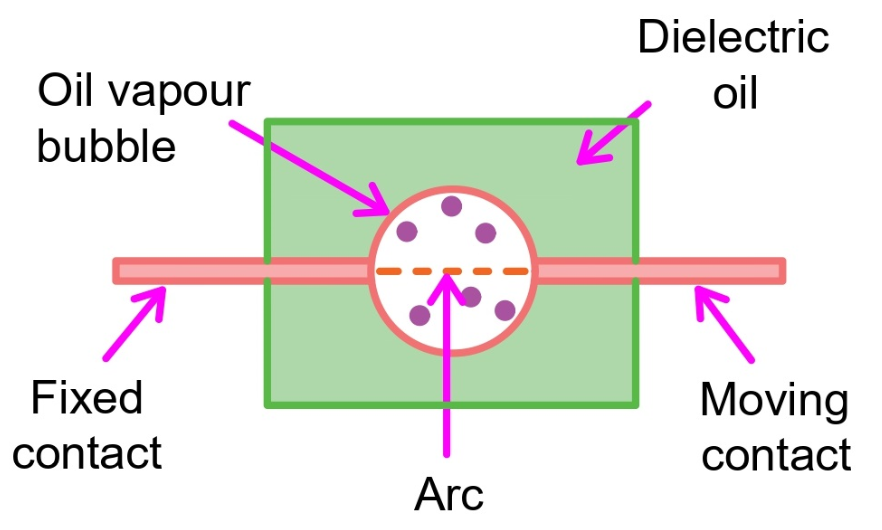

Oil circuit breakers employ insulating oil to both cool the arc and provide dielectric insulation. When a fault occurs, the breaker’s contacts separate inside an oil-filled chamber. The arc formed between the contacts generates intense heat, which vaporizes the oil and creates hydrogen gas. This gas surrounds and cools the arc, helping extinguish it.

The oil not only quells the arc but also insulates the contacts from grounded parts. These breakers are suitable for high-voltage systems and are often deployed in substations and transmission lines.

There are two main types of oil circuit breakers:

- Bulk Oil Circuit Breaker (BOCB): Uses large volumes of oil for both insulation and arc extinction.

- Minimum Oil Circuit Breaker (MOCB): Uses a minimal amount of oil, confined to the arc chamber, reducing the risk and cost.

While oil circuit breakers are robust and long-serving, they do have drawbacks such as fire hazards, oil degradation, and environmental concerns. Nevertheless, they remain relevant in legacy systems and are valued for their simplicity and durability.

➡️ Explore more: Oil Circuit Breaker – Construction, Working & Maintenance

Air Circuit Breaker

An Air Circuit Breaker (ACB) uses air as the arc-extinguishing medium. It is primarily used in low- and medium-voltage applications, such as industrial power distribution and control panels. Air circuit breakers are designed for rapid operation and are available in indoor-mounted configurations.

There are two major types of air circuit breakers:

- Air Break Circuit Breakers (operate at atmospheric pressure)

- Air Blast Circuit Breakers (use compressed air for arc extinction)

In both types, the arc formed between contacts during operation is extinguished by cooling, lengthening, and splitting the arc path using specially designed arc runners and chutes. The interruption generally occurs around the current zero crossing of the AC waveform when the arc voltage exceeds the system voltage.

Advantages

- Simple and compact design

- Suitable for frequent operation

- Quick arc quenching

- Easy maintenance compared to oil circuit breakers

Disadvantages

- High noise (especially in air blast types)

- Less effective at very high voltages

- Arc control at low current may be less efficient

➡ Read in detail: Air Break Circuit Breaker – Working, Applications

SF6 Circuit Breaker

SF₆ (Sulphur Hexafluoride) circuit breakers use pressurized SF₆ gas as both an arc-quenching and insulating medium. Known for its superior dielectric strength and fast arc-extinguishing capability, SF₆ breakers are widely used in high-voltage applications up to 760 kV.

Unlike air or oil circuit breakers, SF₆ breakers offer quicker arc interruption and higher reliability. They are ideal for power grids, substations, railways, and renewable energy systems.

For detailed construction, working, advantages, and types, read our full guide on SF₆ Circuit Breaker.

Vacuum Circuit Breaker

A vacuum circuit breaker (VCB) uses a high-vacuum interrupter chamber to quench the arc formed during circuit interruption. The vacuum provides excellent dielectric strength and ensures quick arc extinction at current zero.

The VCB’s arc quenching chamber—typically made of ceramic or metal—is hermetically sealed and maintained at very low pressure (up to 10⁻⁶ torr). This sealed environment allows the breaker to interrupt fault currents efficiently with minimal contact wear.

Due to their compactness, fast operation, and minimal maintenance requirements, vacuum circuit breakers are well-suited for medium-voltage applications ranging from 6.6 kV to 33 kV. They are commonly used in indoor switchgear, industrial power systems, and substations.

Read our full guide on Vacuum Circuit Breaker – Working, Construction & Advantages

Comparison Table: Oil vs SF₆ vs Vacuum vs Air Circuit Breaker

Here is a comparison table for Oil, SF₆, Vacuum, and Air Circuit Breakers based on key parameters.

| Parameter | Oil Circuit Breaker | SF₆ Circuit Breaker | Vacuum Circuit Breaker | Air Blast Circuit Breaker |

|---|---|---|---|---|

| Arc Quenching Medium | Mineral Oil | Sulfur Hexafluoride (SF₆) Gas | Vacuum (high vacuum environment) | Compressed Air |

| Arc Quenching Method | Decomposition of oil forms hydrogen gas | Electron absorption by SF₆ gas | Arc is extinguished quickly in vacuum | Arc is blown away by air blast |

| Dielectric Strength | Moderate | Very High | Very High | Low to Moderate |

| Operating Voltage Range | Medium to High Voltage | Medium to High Voltage | Low to Medium Voltage | Low Voltage |

| Maintenance Requirements | Moderate (oil replacement, testing) | Low (but gas leakage must be monitored) | Very Low | Moderate (air system maintenance) |

| Size and Weight | Bulky and heavy | Compact but needs sealed units | Very compact | Bulky (due to air compression system) |

| Environment Concerns | Oil disposal and fire hazard | Greenhouse gas emission if leaked | Eco-friendly | High noise and pressure handling |

| Interrupting Time | Slow to Moderate | Fast | Very Fast | Fast |

| Cost | Low to Moderate | High | High | Moderate |

| Applications | Substations, outdoor HV switchyards | GIS, HV substations, power plants | Commercial, industrial, indoor switchgear | Distribution panels, industries |

Applications of Circuit Breaker

Circuit breakers are extensively utilized across various fields of electrical engineering. They serve crucial purposes such as:

- Power generation: Circuit breakers are devices that protect generators from overloads, short circuits, and reverse power flow. They also facilitate the synchronization and parallel operation of generators.

- Power transmission: Circuit breakers protect transmission lines from faults, lightning strikes, and switching surges. They also allow for the sectionalizing and load-shedding of power systems.

- Power distribution: Circuit breakers protect power system equipment from faults, overloads, and under-voltage while also managing loads and responding to demand.

- Industrial: Circuit breakers protect industrial equipment from faults, overloads, phase imbalance, etc. They also enable motor speed control and soft starting.

- Commercial: Circuit breakers are used to protect commercial buildings, such as offices, malls, hotels, hospitals, etc., from faults, overloads, power surges, etc. Energy management and automation of building systems are also facilitated by them.

- Rail: Circuit breakers protect rail vehicles from faults, overloads, and short circuits and enable traction control and regenerative braking.

Conclusion

Circuit breakers are critical devices used for protecting and managing electrical power systems. They can interrupt high fault currents, isolate faulty sections, and restore operation after maintenance or repairs.

Electrical engineers can isolate and switch different parts of the power system for maintenance and control purposes. They use various arc quenching media such as oil, air, SF6, or vacuum, depending on the voltage level and current rating of the circuit.

They are superior to fuses in terms of repeatability, selectivity, reliability, and durability.

However, they have some drawbacks, such as complexity, cost, maintenance, and failure. Nevertheless, they are widely used in various fields of electrical engineering, such as power generation, transmission, distribution, industrial, commercial, and rail.