A circuit breaker is a type of switch that is designed to interrupt the flow of nominal, abnormal, or fault current. Whenever a high magnitude of current flows through the circuit, the circuit breaker works as a mechanical device that can easily cut off the power supply and protect the electrical system from damage. Its primary function is to open or close an electrical circuit and prevent the occurrence of any electrical mishap.

A circuit breaker is a safety switch that automatically stops the flow of current in an overloaded electric circuit, ground faults, or short circuits after protective relays detect a fault.

Working Principle of Circuit Breaker

A circuit breaker has fixed and moving contacts. These contacts touch each other and carry current when the circuit is closed under normal conditions. The contacts engage each other under the pressure of a spring when the circuit breaker is closed.

Under normal operating conditions, the circuit breaker’s arms can be opened or closed to switch and maintain the system. To open the circuit breaker, you only need to apply pressure to a trigger.

Whenever a fault occurs in the system, the breaker’s trip coil gets energized, causing the moving contacts to separate, thus opening the circuit.

How Does a Circuit Breaker Clears the Fault?

- Detection of Fault: The protection relay detects faults, such as overloads or short circuits.

- Activation of Mechanism: After detecting a fault, the protection relay issues a trip command to the circuit breaker, and the breaker initiates a mechanism that releases stored potential energy.

- Separation of Contacts: This energy separates the two main contacts of the circuit breaker: a fixed contact and a moving contact.

- Arc Formation: The separation of contacts produces a high-energy plasma called an arc.

- Arc Quenching: The breaker uses various methods to extinguish the arc, such as cooling, compressing, or replacing the ionized medium with fresh gas.

- Current Interruption: The process involves interrupting the flow of current, which stops any damage caused by the fault condition

- Resetting: After the fault is resolved, the circuit breaker can be reset manually or automatically, allowing the current to flow again.

- Re-establishment of Contacts: Resetting the circuit breaker reconnects the fixed and moving contacts, allowing current to flow through the circuit again.

Types of Circuit Breaker

Circuit breakers are classified based on their rated voltages. Those rated below 1000V are low-voltage circuit breakers, while those rated above 1000V are high-voltage circuit breakers.

The different types of circuit breakers can be classified based on the medium used for arc extinction.

- Oil Circuit Breaker

- Bulk Oil Circuit Breaker

- Minimum Oil Circuit Breaker

- Air Circuit Breaker

- Sulphur Hexafluoride (SF6) Circuit Breaker

- Vacuum Circuit Breaker

All high-voltage circuit breakers can be classified into two main categories: oil circuit breakers and oil-less circuit breakers.

Oil Circuit Breaker

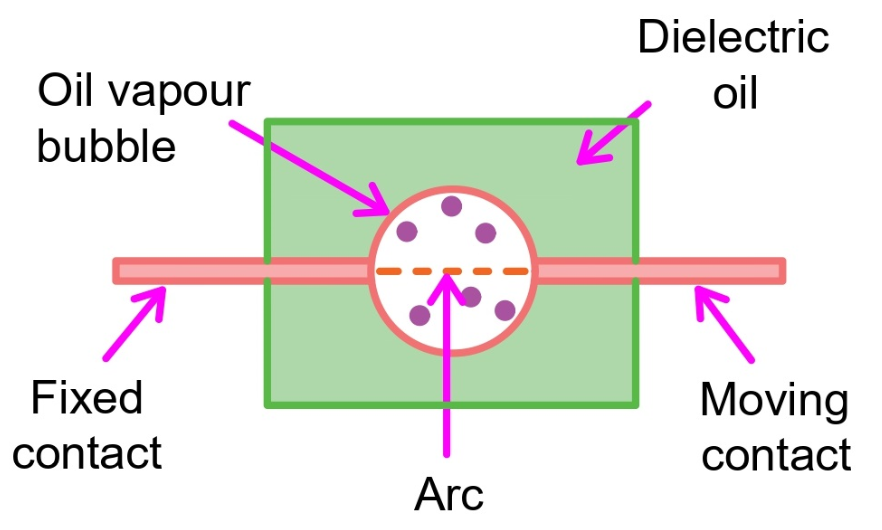

The oil circuit breakers utilize mineral oil as the arc quenching medium. It immerses the contacts in an oil-filled chamber that acts as an insulator while providing high dielectric strength and cooling properties.

When the contacts of the circuit breaker open, the electric current creates an arc that draws in the surrounding oil. This process decomposes the oil into hydrogen gas and other byproducts. The gas bubbles then surround the arc, which cools and reduces the pressure of the arc. Additionally, the oil acts as a barrier to prevent the arc from reigniting.

Oil circuit breakers can interrupt high-voltage circuits and are used for transmission lines and substations. They have low maintenance costs and long service life.

There are certain risks associated with oil circuit breakers that need to be managed. These risks must be carefully considered and addressed to ensure the safe and effective operation of the equipment.

- There is a risk of oil leakage and fire.

- Over time, there is a possibility of oil contamination and deterioration.

- Large size and weight

- Environmental concerns

Read More: Oil Circuit Breaker

Air Circuit Breaker

Air circuit breakers utilize compressed air to quench the arc. The fixed and moving contacts of the circuit breaker are housed in an air-tight chamber. The air-tight chamber is connected to an air compressor.

When the contacts open, the air blast is directed toward the arc to blow it away from the contacts. The air cools down the contacts and removes the ionized particles from the gap.

Air circuit breakers can interrupt the current at low voltage, and they are suitable for low-voltage applications like distribution panels and industrial circuits. They operate at high speed and have low arc energy. However, they also have some disadvantages.

- High noise level

- High operating pressure

- Sensitivity to voltage fluctuations

- High cost of installation and maintenance

Read More: Air Circuit Breaker

SF6 Circuit Breaker

An SF6 circuit breaker utilizes sulfur hexafluoride gas to extinguish the electrical arc. This gas has high dielectric strength and exceptional arc-quenching properties. The circuit breaker’s contacts are enclosed within a sealed chamber filled with SF6 gas at low pressure.

When the contacts open, the gas flows through a nozzle and hits the arc. The gas absorbs free electrons in the arc, forming negative ions that lower its conductivity and increase resistance. The gas also cools down the contacts and prevents them from restriking.

SF6 circuit breakers are used in medium and high-voltage applications like power plants and switchyards. They have low maintenance requirements and long service life. However, they also have some disadvantages.

- High cost of SF6 gas

- Gas leakage has an impact on the environment.

- There is a problem with disposing of gas.

- Special handling and safety precautions are necessary.

Read More about– SF6 Circuit Breaker

Vacuum Circuit Breaker

A vacuum circuit breaker employs a vacuum to extinguish electric arcs. The vacuum has high dielectric strength and low arc resistance, so it is an effective medium. The breaker’s contacts are housed within a ceramic or metal chamber, which is then evacuated to a very low pressure.

When the contacts open, the arc is quickly extinguished in a vacuum. Interruption is fast due to low arc resistance and high dielectric strength.

Vacuum circuit breakers are ideal for low and medium-voltage applications, such as commercial and industrial circuits. They offer low arc energy and noise levels, high reliability, and durability. However, there are a few drawbacks associated with them, including:

- High cost of manufacturing and testing

- The current rating and breaking capacity are limited.”

- It can be difficult to detect a loss of vacuum

- It is important to handle ceramic or metal chambers with special care to avoid any damage.

Applications of Circuit Breaker

Circuit breakers are extensively utilized across various fields of electrical engineering. They serve crucial purposes such as:

- Power generation: Circuit breakers are devices that protect generators from overloads, short circuits, and reverse power flow. They also facilitate the synchronization and parallel operation of generators.

- Power transmission: Circuit breakers protect transmission lines from faults, lightning strikes, and switching surges. They also allow for the sectionalizing and load-shedding of power systems.

- Power distribution: Circuit breakers protect power system equipment from faults, overloads, and under-voltage while also managing loads and responding to demand.

- Industrial: Circuit breakers protect industrial equipment from faults, overloads, phase imbalance, etc. They also enable motor speed control and soft starting.

- Commercial: Circuit breakers are used to protect commercial buildings, such as offices, malls, hotels, hospitals, etc., from faults, overloads, power surges, etc. Energy management and automation of building systems are also facilitated by them.

- Rail: Circuit breakers protect rail vehicles from faults, overloads, and short circuits and enable traction control and regenerative braking.

Conclusion

Circuit breakers are critical devices used for protecting and managing electrical power systems. Circuit breakers have the ability to interrupt high fault currents and restore the normal operation of the circuit.

Electrical engineers can isolate and switch different parts of the power system for maintenance and control purposes. They use various arc quenching media such as oil, air, SF6, or vacuum, depending on the voltage level and current rating of the circuit.

They are superior to fuses in terms of repeatability, selectivity, reliability, and durability.

However, they have some drawbacks, such as complexity, cost, maintenance, and failure. Nevertheless, they are widely used in various fields of electrical engineering, such as power generation, transmission, distribution, industrial, commercial, and rail.