The air break circuit breaker is designed to initiate and extinguish arcs in relatively still air. They are typically used for low voltages, usually up to 15KV, and have a rupturing capacity of 500MVA. Air circuit breakers have several advantages as an arc quenching medium compared to oil-based breakers. These are as follows.

- The elimination of risks and maintenance associated with the use of oil.

- The gas pressure and oil movement create no mechanical stress.

- Regular oil replacement costs are eliminated since the oil does not deteriorate with successive breaking operations.

The air break circuit breaker operates by separating the contacts and extinguishing the arc in the air at atmospheric pressure. This circuit breaker employs the high resistance principle and uses arc runners and arc chutes to expand the arc. The arc resistance is increased by splitting, cooling, and lengthening.

The voltage drop across the arc becomes greater than the system voltage, causing the arc to extinguish at the current zero of the AC wave due to increased arc resistance.

Air break circuit breakers are used in both DC and AC circuits up to 12,000 volts. These breakers are typically of the indoor type and are installed on vertical panels or indoor draw-out switchgear. AC circuit breakers are commonly used in indoor medium-voltage and low-voltage.

Plain Break Type Air Break Circuit Breaker

It is the simplest type, with two horn-shaped pieces. When the air first moves between the horns, it is pushed upwards by the convection currents that occur due to the heating of the air during the arcing process and the interaction of the magnetic and electric fields. If the horns are fully separated, the arc will stretch from one tip to the other, causing the arc to become longer and cooler.

The possibility of slow arc spreading of adjacent metal works limits the application of circuits above 500V and too low power..

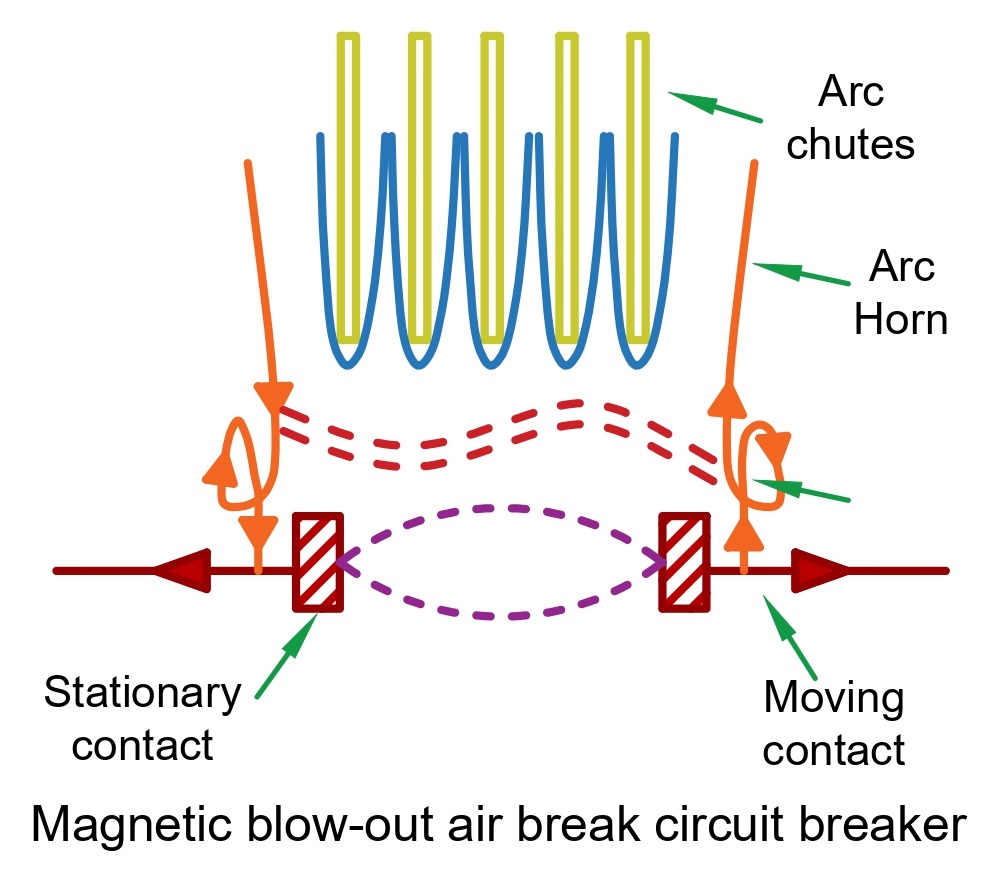

Magnetic Blow-Out Type Air Break Circuit Breaker

Air circuit breakers are used in circuits with voltage up to 11 KV. To extinguish arcs created during the interruption of the circuit, magnetic fields are generated by blowout coils connected in series. These are called blowout coils. The magnetic field doesn’t extinguish the arc by itself. Instead, it moves the arc into chutes, where it is lengthened, cooled, and eventually extinguished. Arc shields prevent the arc from spreading to an adjacent network.

To direct the arc upward, the coils must be connected with the correct polarity. As the breaking action becomes more effective with larger currents, this principle increases the rupturing capacities of such breakers to higher values.

The arc chute is essential for ensuring the safe and efficient operation of electrical systems. It performs three interrelated crucial functions by efficiently extinguishing arcs in the air.

- Confines the arc within a restricted space

- Provides magnetic control to ensure arc movement is contained and extinguished

- Quick cooling of arc gase ensures that the arc is extinguished by deionization.

Air Chute Air Break Circuit Breaker

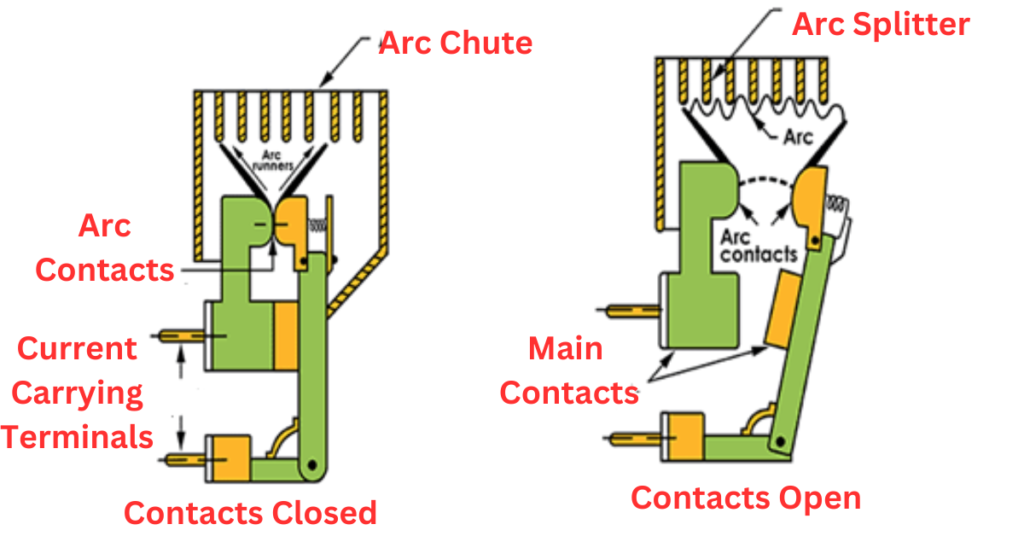

The figure below shows the typical air-chute break circuit breaker setup for low- and medium-voltage circuits.

This breaker consists of two sets of contacts – the main contacts and the arcing or auxiliary contacts. The main contacts are made of copper and conduct current when the breaker is closed. They have low contact resistance and are plated with silver.

The arcing contacts are made of a hard, heat-resistant copper alloy. They are used to protect the main contacts from damage caused by arcing. When necessary, the arcing contacts can be easily replaced. During operation, the auxiliary and arcing contacts close before the main contacts and open after them.

The blowouts in this system consist of steel inserts placed in the arcing chutes. These inserts are arranged so that the magnetic field induced by the current in the arc moves it upwards at a faster rate. The steel plates divide the arc into multiple smaller arcs in a series.

The voltage distribution along the arc length is non-linear and is accompanied by significant anode and cathode drops. If the sum of anode and cathode drops of all the short arcs in series exceeds the system voltage, it automatically creates conditions for the arc to be quickly extinguished.

When the arc comes into contact with the relatively cool surfaces of the steel, it gets rapidly and effectively cooled. The movement of the arc may be natural or aided by a magnetic blowout. As a result, the arc is extinguished by reducing its power and increasing its loss.

Working Principle Air Break Circuit Breaker

When a fault occurs, the first thing that happens is that the main contacts separate, and the current is shifted to the arcing contacts. Next, the arcing contacts separate, forming an arc between them. This arc is then forced upwards by electromagnetic forces and thermal action. The arc ends are directed along the arc runner and move upwards until they reach the arc splitter plates. Finally, the arc is extinguished by various methods, including lengthening, cooling, and splitting.

Applications of Air Break Circuit Breaker

The air break circuit breaker is ideal for controlling power station auxiliaries and industrial plants. It doesn’t need any additional equipment, such as compressors. They are commonly used in areas where fire or explosion hazards are present. The air break principle of lengthening the arc and utilizing arc runners and magnetic blow-up is employed for DC circuit breakers up to 15 KV.

Drawback of Air Break Circuit Breaker

The arc chute principle has the disadvantage of being ineffective at low currents due to weak electromagnetic fields. Although the lengthening and deionizing action of the chute is not necessarily less efficient than at high currents, the arc movement into the chute tends to become slower, and high-speed interruption is not necessarily achieved.