Definition: A circuit breaker that uses a small amount of oil as an arc quenching medium is called a minimum oil circuit breaker. It is also known as a low-oil circuit breaker. The oil in this type of circuit breaker is used only for arc extinction and not for insulating the current-carrying contacts from the earth. In contrast, the bulk oil circuit breaker uses oil for both arc extinction and insulation purposes. The minimum oil circuit breaker requires only about 10% of the oil used in bulk oil circuit breakers.

Construction of Minimum Oil Circuit Breaker

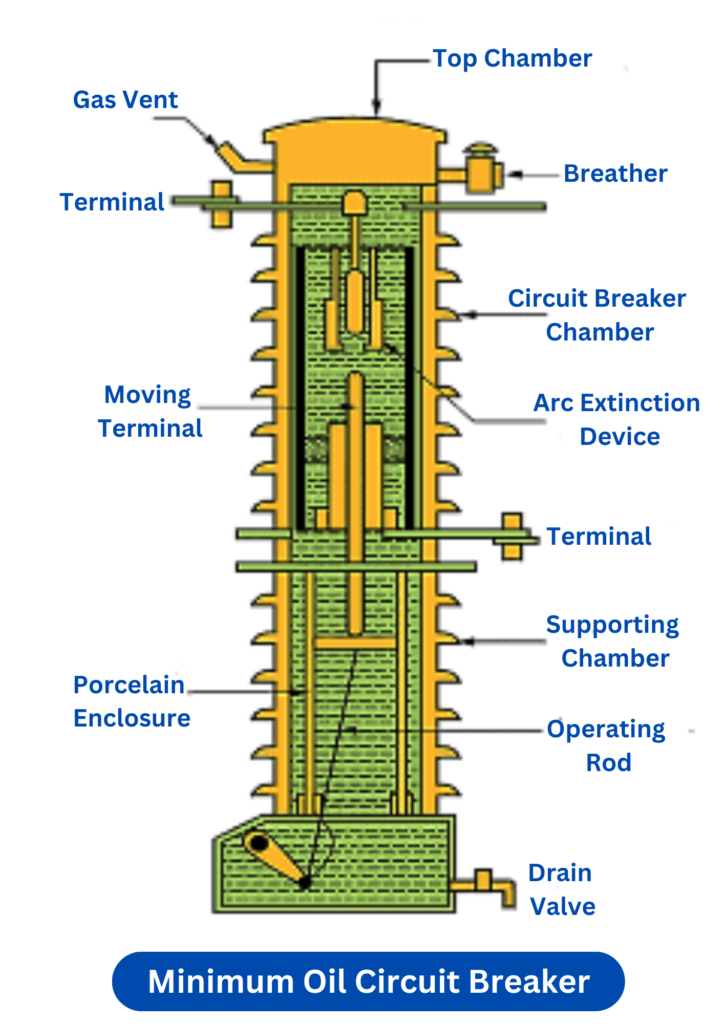

The minimum oil circuit breaker (MOCB) consists of two oil-filled chambers, the supporting and the circuit-breaking chambers, which are separated from each other.

The circuit-breaking chamber is a porcelain enclosure filled with oil to extinguish the arc when circuit breaking occurs. It comprises an arc control device and upper and lower fixed contacts.

The lower fixed contact is ring-shaped, and the moving contact can slide through it. There is a constant electrical connection between the contact that moves and the contact that remains fixed below it. The upper and lower fixed contacts are used to take out the terminals of the circuit breaker.

The process of extinguishing an electric arc is performed by the arc control device, which is attached to the upper fixed contact. This device contains both axial vents for interrupting low currents and radial vents for interrupting high currents. Because of this, the circuit breaking chamber is called an arc extinction chamber. Below is a diagram that illustrates the construction of a single-phase minimum oil circuit breaker.

The diagram of the minimum oil circuit breaker(MOCB) is shown in the image below.

The supporting chamber is a porcelain enclosure that is filled with oil. The oil present in the supporting and circuit breaking chambers does not come into physical contact with each other. Additionally, the oil in the supporting chamber is not involved in the arc extinction process. Its sole purpose is to provide insulation, which is why it is also known as the dielectric supporting chamber.

An operating rod is fixed to the moving contact, which is made to move through the supporting chamber. This operating rod provides vertical movement to the moving contact, allowing it to make and break the circuit. The supporting and circuit breaking chambers are separate enclosed chambers, each with cylindrical-shaped synthetic resin-bonded papers within porcelain insulators.

The circuit-breaking chamber is mounted with a metal top chamber, which allows for expansion space of insulating oil in the compartment. The top chamber contains the breather and gas vent. The breather is used to regulate the volume of oil during changes in atmospheric temperature. The purpose of the gas vent is to remove the gases that are produced in the circuit-breaking compartment.

Working of Minimum Oil Circuit Breaker

During normal operation, the moving contact stays in touch with the upper fixed contact. However, in case of a fault, the operating rod controlled by the operating mechanism pulls the moving contact down. As the moving contact begins to separate, an arc is created between the two contacts.

When the contacts are surrounded by oil during an electrical arc, the temperature of the oil increases. As a result, the oil surrounding the arc becomes very hot and vaporizes, producing gases that expand inside the chamber. This increase in pressure causes the gases to move upward by splitting the arc and cooling the contacts.

As the gases move upwards, fresh oil fills the space previously occupied by them. Due to the energy created by the arc, the oil surrounding the arc decomposes and releases gases, increasing the pressure inside the chamber. This pressure forces the gases to move upwards and be replaced by fresh oil once again.

During the process of extinguishing an arc, the fresh oil between the contacts is continuously replaced until the arc is completely extinguished at the instant of current zero. However, to prevent the arc from reigniting after current zero, the dielectric strength of the medium (oil) must be maintained at a high level. This can be achieved by implementing various methods.

It is important to maintain high oil pressure inside the chamber so that the fresh oil can push between the contacts while the gases move upwards. This will force fresh oil onto the arc with the help of the piston action produced by the operating rod fixed to the moving contact.

Advantages of Minimum Oil Circuit Breaker

A minimum oil circuit breaker is an improvement over a bulk oil circuit breaker due to the fact that it requires less oil, thus making it more cost-effective and eco-friendly.

- Compared to Bulk Oil Circuit Breakers (BOCB), Minimum Oil Circuit Breakers (MOCB) require less oil.

- The risk of fire and explosion is lower in MOCB than in BOCB.

- The weight of MOCB is significantly lower than BOCB due to reduced steel requirements for the tank.

- The size of MOCB is quite small.

- It is easier to access the contacts in MOCB.

- MOCBs can be installed indoors and outdoors, while BOCBs are only suitable for outdoor use.

- The storage of a large amount of high-grade mineral oil (or transformer oil) in generating stations and substations is made safer with MOCBs.

- MOCB circuit breakers cost less than other circuit breakers with the same rating.

Disadvantages of Minimum Oil Circuit Breaker

A minimum oil circuit breaker has some disadvantages compared to a bulk oil circuit breaker.

- Increased degree of carbonization

- It is difficult to eliminate the gases present in the contact space on time.

- The oil’s dielectric strength rapidly deteriorates due to carbonization.