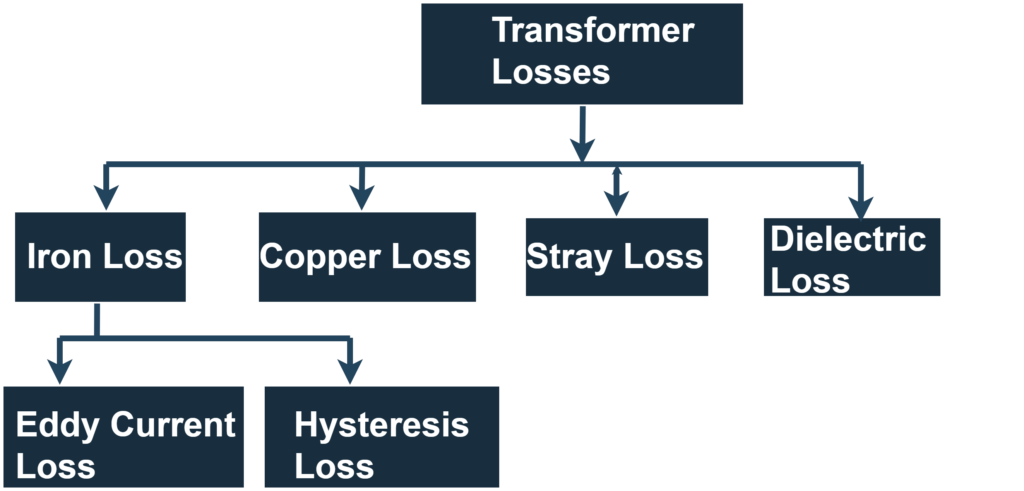

Iron Loss, Hysteresis Loss, Eddy Current Loss, Copper Loss, Stray Loss, and Dielectric Loss are the types of losses in a transformer.

Transformers play a key role in power systems. The transformer transfers electrical energy between different voltage levels. However, transformers are not 100% efficient. This is because certain losses occur during their operation. These losses are known as transformation losses. These losses affect the efficiency and performance of the transformer. You can reduce energy wastage and improve the efficiency of the transformer by understanding the types of losses that occur in a transformer.

Types of Losses in a Transformer

The broad categories of transformer losses are – Core loss and Copper loss. In addition to these losses, Stray Loss and Dielectric Loss occur in a transformer.

1. Iron Losses

When the primary winding gets an alternating voltage, it creates an alternating magnetic flux in the core. The core of the transformer carries the magnetic flux. The magnetic flux is alternating and loss caused by the magnetic flux is called the core loss or iron loss. These losses are independent of transformer loading and remain constant under specified operating conditions. Core loss has two main parts: hysteresis loss and eddy current loss.

Hysteresis Loss

Hysteresis loss occurs in the magnetic core of a transformer. When AC supply is applied to the primary winding, the alternating magnetic flux is created in the core. The flux repeatedly magnetizes and demagnetizes the core material. The magnetic domains in the core align and realign with the changing magnetic field. In this process, energy is lost in the form of heat.

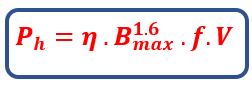

The formula to calculate this loss is given as,

Where:

- η = Hysteresis constant (depends on the core material)

- Bmax = Maximum flux density in wb/m2

- f = Frequency of AC supply( Hz)

- V = Volume of the core (m3)

The hysteresis loss depends on the core material. This loss can be reduced by using the CRGO (Cold Rolled Grain Oriented) core material for the transformer core.

Eddy Current Loss

When magnetic flux links to a closed circuit, an electromotive force (EMF) is induced. The EMF causes the current to flow in the circuit. The magnitude of the current depends on the EMF and the resistance of the circuit. The transformer core is made of a conducting material and has finite resistance. The induced EMF causes the currents to flow in the core material, and these currents are called eddy currents.

The eddy currents do not perform any useful work, they result in energy loss in the magnetic material. The loss caused by eddy currents is called Eddy Current Loss.

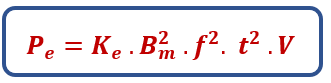

The formula to calculate eddy current loss is given by:

Where:

- Ke = Eddy current constant. Its magnitude depends on factors such as the properties of the magnetic material, including the core’s volume and resistivity, as well as the thickness of the laminations used.

- t = Thickness of the core lamination (m)

- Bm- maximum value of flux density in wb/m2

- f = Frequency of AC supply (Hz)

- V = Volume of the core (m3)

A solid core has higher resistance and contributes to increased eddy current losses. Transformer cores are made using thin laminations to reduce eddy current loss. The laminations are insulated from one another to limit the flow of eddy currents.

2. Copper Loss (Ohmic Loss)

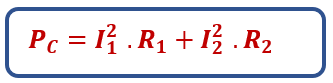

Copper losses happen due to the Ohmic resistance of the transformer windings. If the currents in the primary and secondary windings are I1 and I2, and their resistances are R1 and R2, the copper losses in these windings are I21R1 and I22R2, respectively. The total copper loss is given by:

Copper losses depend on the load and vary as the load changes. Higher currents result in greater copper losses. To reduce these losses, low-resistivity materials are used for transformer windings.

3. Stray Loss

In an ideal transformer, all the magnetic flux links perfectly with primary and secondary windings. However, in a real transformer, magnetic flux does not link perfectly to the primary and secondary windings. Some of the flux leaks out from the core and windings. This leakage flux causes circulating currents in the windings or nearby metal parts and causes I2 R loss. These losses can be reduced by the proper selection and use of insulating materials, the correct placement of windings, and the use of low-resistance windings.

4. Dielectric Loss

Dielectric loss in a transformer happens because of the movement of charges and dipoles in the insulating materials when AC voltage is applied. This loss mainly comes from two sources:

- Conduction Loss – Caused by the small conductivity of the insulating material.

- Polarization Loss – This happens when the polarization of the dielectric material lags behind the alternating electric field.

The formula for dielectric loss is,

Where:

- V = Voltage applied across the insulation

- f= Frequency of the AC supply

- C = Capacitance of the insulating material

- tanδ = Dielectric loss angle

Dielectric loss can be reduced by using high-quality insulating materials that have low-loss angles.

Summary: Types of Transformer Losses

| Type of Loss | Reason | Dependence on | How to Minimize |

|---|---|---|---|

| Hysteresis Loss | magnetization and demagnetization of the magnetic core | Frequency and core material | Use of silicon steel cores ( CRGO) |

| Eddy Current Loss | Induced EMF in the core | Core thickness and supply frequency | Use of laminated thin cores |

| Copper Loss | Resistance of primary and secondary windings | Load current, winding resistance | Use of low-resistivity winding materials |

| Stray Loss | Leakage flux | Core design, material conductivity | Optimize core design and use of non-conductive materials |

| Dielectric Loss | Polarization of insulation | Voltage, frequency, and material quality | Use of high-quality insulating materials |

Conclusion

Understanding the different types of losses in a transformer, like Iron Losses, Hysteresis Loss, Eddy Current Loss, Copper Loss, Stray Loss, and Dielectric Loss, is key to making the transformer more efficient and reliable.

Read Next: