HT switchgears are essential high-voltage control and protection systems used in electrical networks operating above 1.1 kV. They manage power flow, isolate faults, and ensure stable, safe power delivery across industrial, utility, and commercial infrastructures.

What are HT Switchgears?

The full form of HT switchgear is High Tension Switchgear, where “tension” is a legacy term for voltage. In modern electrical systems, it refers to high-voltage switchgear typically operating at 3.3 kV, 6.6 kV, 11 kV, 33 kV, or higher.

These systems consist of protective devices like high voltage circuit breakers, disconnect switches, and relays that detect faults and provide safe circuit isolation to ensure reliable power distribution.

In short, switchgear means a combination of control, switching, and protective devices that manage power flow and safeguard electrical networks.

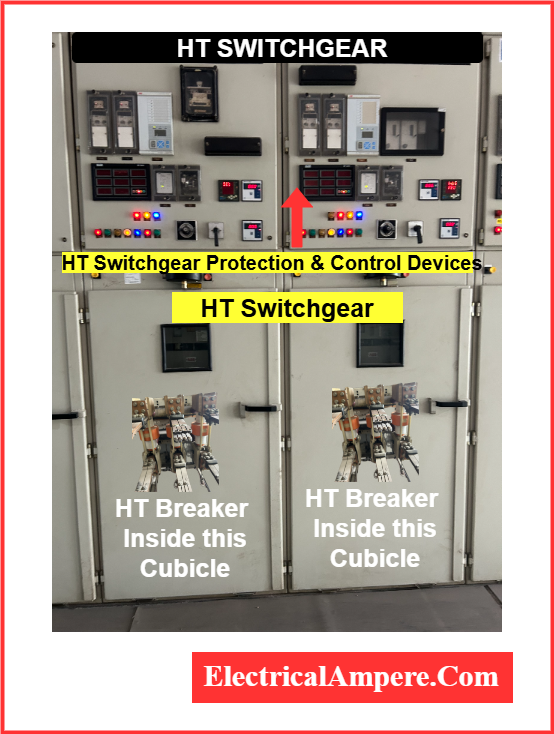

Key HT Switchgear Components

An HT switchgear panel houses multiple components that collectively control, monitor, and protect high-voltage power systems. Below are the major elements:

- High Voltage Circuit Breakers – Used to interrupt fault current safely. Types include VCB, SF6, ACB, and oil breakers.

- Current Transformers (CTs) – Measure current and provide input to protection relays.

- Potential Transformers (PTs) – Step down voltage for monitoring and control.

- Protection Relays – Analyze input from CTs/PTs and trigger breaker tripping during faults.

- Busbars – Distribute power internally across the HT panel system.

- Isolators and Earth Switches – Enable maintenance and grounding for operational safety.

- Meters & Control Units – Facilitate automation, remote control, and system visibility.

These devices are individually important, but together, they enable coordinated protection, monitoring, and seamless operation of the HT system.

Working Principle of HT Switchgear

HT switchgear operates by constantly monitoring electrical parameters and rapidly isolating faulty circuits to maintain power system stability.

- Sensors (CTs and PTs) measure system parameters.

- Relays analyze those parameters and detect faults.

- If a fault is found, the circuit breaker opens instantly.

- Isolators and earthing switches provide further disconnection for safe maintenance.

This quick response minimizes downtime and prevents damage to connected equipment.

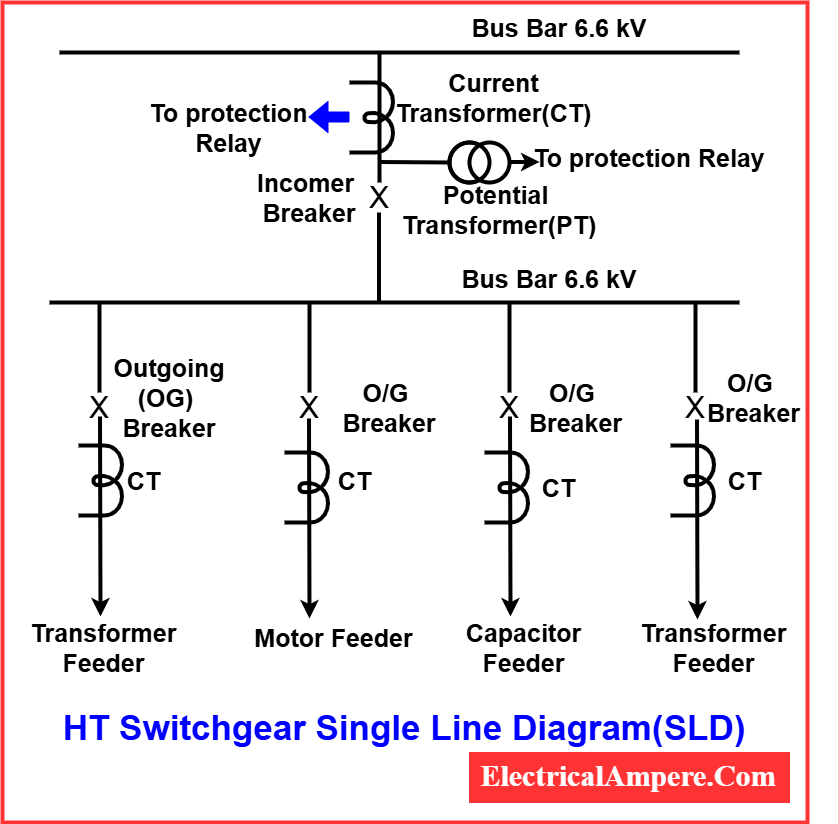

HT Switchgear Single Line Diagram

A simplified HT switchgear SLD:

The single line diagram of an HT switchgear follows the below sequence:

- It begins with the Incoming Line, which carries high-voltage power into the system.

- Next, the power passes through Current Transformers (CTs) and Potential Transformers (PTs). These devices measure electrical parameters and feed data to the Protection Relay.

- The Protection Relay continuously monitors system conditions. If a fault occurs, it sends a trip signal to the Circuit Breaker.

- Once the circuit is secured, power flows into the Busbar, which acts as a central distribution point.

- Finally, electricity is routed to various loads via the Outgoing Feeder.

Types of HT Switchgears

There are various switchgear types based on insulation and arc-quenching methods. Common types include:

1. Vacuum Circuit Breaker (VCB)

- Uses vacuum for arc interruption

- Compact and suitable for indoor use

- Low maintenance and high life expectancy

2. SF6 Circuit Breaker

- Uses sulfur hexafluoride gas for arc extinguishing

- Ideal for high-voltage outdoor installations

- High dielectric strength and reliability

3. Air Circuit Breaker (ACB)

- Uses air to quench arcs

- Suitable for medium-voltage indoor systems

4. Oil Circuit Breaker

- Uses insulating oil as arc-extinguishing medium

- Now outdated due to fire risk and maintenance needs

Comparison of Different HT Circuit Breaker Types

Here’s a quick comparison of the main HT breaker types by insulation method, use case, and core benefits:

| Breaker Type | Insulation Medium | Use Case | Key Advantage |

|---|---|---|---|

| VCB | Vacuum | Indoor | Long lifespan, low maintenance |

| SF₆ | SF₆ gas | Outdoor/High voltage | High dielectric strength |

| ACB | Air | Medium voltage | Simpler design |

| Oil | Oil | Legacy systems | Historically common, now less used |

Where are HT Switchgears Used? Key Applications

HT switchgears are deployed wherever high-voltage power distribution is required:

- Substations and power plants

- Large industrial facilities

- Commercial buildings

- Renewable energy systems (solar, wind)

- Transmission and distribution networks

Their main job is to protect systems and allow safe, controlled power delivery.

Advantages of HT Switchgears in Power Systems

- Prevents damage from overloads and short circuits

- Allows remote control and monitoring

- Ensures operator safety during maintenance

- Minimizes outages and equipment downtime

- Compatible with smart grid automation

Safety Aspects of HT Switchgears

HT switchgears operate at high voltages, requiring strict adherence to safety standards to protect both equipment and personnel.

One key safety measure is proper insulation, which prevents voltage leakage and accidental contact. Equally important are arc-quenching methods like vacuum or SF6 that safely interrupt fault currents during abnormal conditions.

Effective grounding systems help redirect fault currents and minimize electrical hazards. In addition, interlocking mechanisms ensure that switching or maintenance operations are only performed under safe, predefined conditions.

Protection relays play a critical role in identifying faults and instantly isolating affected circuits. This prevents equipment damage and reduces the risk of dangerous arc flash incidents.

Routine inspection and maintenance ensure long-term system reliability. Operators must also follow LOTO (Lockout/Tagout) procedures and wear appropriate PPE (Personal Protective Equipment) to avoid injury during operation or servicing.

Together, these safety practices form the foundation of secure and reliable HT switchgear operation.

Conclusion: Why HT Switchgears Matter

HT switchgears form the protective backbone of high-voltage electrical systems. From switchgear panels to high voltage circuit breakers, these components ensure fault-free, reliable operation. Whether you’re designing a substation or upgrading industrial power infrastructure, understanding HT switchgear types, components, and working principles is essential for safe and efficient power management.

Related Articles:

- What Are LT and HT Panels? Types, Uses, and Key Differences

- What is the Difference Between HT and LT Motor?

- HT Panel- Function, Components, Working, Features

- LT Panel- Definition, Purpose, Types, Components, Design

- What is LT and HT Line? Difference Between LT and HT?

- High Tension (HT) Power Cable: Types, Parts, and Applications