Explore the different types of electrical substations, including step-up, step-down, distribution, mobile, and more. Learn about their functions, voltage levels, and designs in our comprehensive guide.

As the demand for electrical power continues to grow, it can be met through power generation substations.

There are different types of power generation substations, including thermal, nuclear, and hydroelectric, each utilizing specific energy sources to generate electricity efficiently.

The location of these substations depends on resource availability, but they are often situated far from load centers (areas with high electricity demand). Since the actual power consumption occurs at these load centers, electricity must be transmitted over long distances from the substations.

This requires the establishment of extensive transmission networks.

While power is generated efficiently at lower voltage levels, transmitting it at higher voltage levels is more cost-effective due to reduced energy losses. To regulate voltage levels and ensure efficient power delivery, multiple switching and transformation stations are installed between the power generation facility and the end consumers.

These stations, commonly known as electrical substations, play a crucial role in the power distribution system. This article explores the different types of substations and their functions.

What is a Substation?

A substation is a crucial component of the electrical power system, designed to regulate, control, and distribute electricity efficiently. It serves as an intermediary between power generation plants and end users, facilitating the safe and reliable transmission of electricity.

One of the primary functions of a substation is voltage conversion, ensuring that power is transmitted at optimal levels to minimize energy losses. While some substations are designed for simple operations with integrated transformers and switches, others are large-scale facilities equipped with multiple components, including:

- Transformers – Used to step up or step down voltage levels.

- Circuit breakers – Protect electrical circuits by interrupting excessive current flow.

- Equipment – Various devices for monitoring, control, and protection.

- Switches – Help manage power flow and isolate faulty sections.

Although substations are primarily associated with AC power transmission, some are specifically designed to convert alternating current (AC) into direct current (DC) for specific applications such as high-voltage direct current (HVDC) transmission systems.

Importance of a Substation

- Acts as a bridge between power generation units and end users, ensuring efficient electricity transmission.

- Regulates power flow by adjusting current and voltage levels as needed.

- Ensures system stability using key components such as:

- Transformers – Step up or step down voltage for efficient transmission.

- Insulators – Prevent leakage currents and enhance safety.

- Circuit breakers – Protect the system from faults and overloads.

- Manages critical electrical parameters, including:

- Frequency control

- Voltage regulation

- Power Factor (P.F.) adjustment

- AC to DC conversion

- Supports reliable power distribution, ensuring a stable and uninterrupted electricity supply to homes, businesses, and industries.

Types of Substations

Electrical substations are categorized based on their function, power handling capacity, and structural design. The four main types of substations include:

- Based on Application:

- Based on Services Provided:

- Based on Operating Voltage Levels:

- Based on Location and Design:

Each type of substation serves a specific role in power generation, transmission, and distribution, ensuring a stable and efficient electrical network.

Types of Substations Based on Application

Substations are classified according to their specific applications in the power system. The main types include:

- Step-up Substation – Increases voltage for efficient long-distance power transmission.

- Step-down Substation – Reduces voltage for safe distribution to consumers.

- Primary Substation – Handles high-voltage power from transmission lines and steps it down for regional distribution.

- Secondary Substation – Further reduces voltage from primary substations for local distribution.

- Distribution Substation – Delivers electricity at usable voltage levels to homes and businesses.

- Mobile Substation – A temporary or emergency substation used during maintenance or power failures.

- Industrial Substation – Supplies power to factories and large industrial facilities.

- Mining Substation – Provides power to mining operations, often in remote areas.

Each type of substation plays a critical role in ensuring efficient and reliable power distribution across different sectors.

1). Step-up Substation

A step-up substation is directly connected to power generation stations because electricity is initially produced at lower voltages. To ensure efficient long-distance power transmission, these voltages must be increased. By stepping up the voltage, energy losses are minimized, making transmission more effective.

Step-up substations typically include transformers to raise voltage levels and circuit breakers to protect both transmission and generation circuits by shutting them down when necessary. The required output voltage is carefully determined based on transmission needs and customer requirements, ensuring a stable and efficient power supply.

2). Step-Down Substation

Step-down substations are connected to load centers to supply electricity at appropriate voltage levels for different types of consumers. These substations reduce high transmission voltages to around 33kV, making the power suitable for further distribution.

The electricity from a step-down substation is then supplied to distribution substations, which further lower the voltage for residential and commercial use. Additionally, some of the power is directly drawn from the substation for industrial applications, where higher voltage levels are required for heavy machinery and equipment.

3) Primary Substation

Primary grid substations serve as crucial nodes in the power transmission network, connecting bulk load centers to the primary transmission system. They step down high-voltage electricity from transmission lines to lower voltage levels suitable for secondary transmission. These substations typically contain transformers, circuit breakers, and protective devices to ensure reliable and efficient power flow. They play a key role in stabilizing voltage levels and preventing power losses over long-distance transmission.

4) Secondary Substation

Secondary substations are strategically located along secondary transmission lines near consumer load centers. Their primary function is to further step down voltage from the primary substations to levels suitable for distribution. These substations typically supply power to industrial, commercial, and residential areas. Equipped with transformers, switchgear, and protective relays, secondary substations ensure safe and efficient power distribution while minimizing voltage fluctuations and ensuring power quality for end users.

5) Distribution Substation

Distribution substations are strategically positioned where primary distribution voltages are further stepped down to levels suitable for consumer use. These substations play a critical role in delivering electricity to residential, commercial, and industrial consumers. They are designed to handle high-voltage electricity and transform it into usable voltages for end users.

A typical distribution substation consists of transformers, switchgear, circuit breakers, and protective devices. The voltage levels at these substations typically include:

- Three-phase voltage: 440V between conductors

- Single-phase voltage: Approximately 230V between neutral and conductor

The design of distribution substations ensures reliability, safety, and efficient power delivery. They are classified based on the type of equipment used and their configuration:

- Conventional Substation: Outdoor substation with air-insulated equipment.

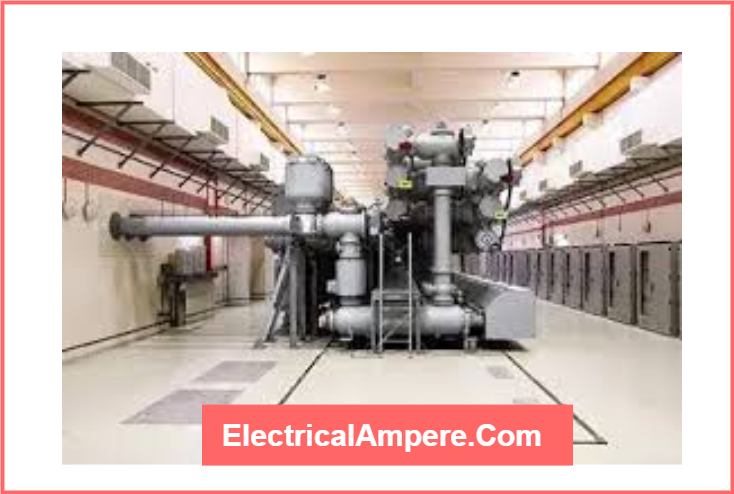

- Indoor Air-Insulated Substation: Located indoors with air-insulated electrical components.

- SF₆ Gas-Insulated Substation (GIS): Uses sulfur hexafluoride (SF₆) gas for insulation, making it compact and suitable for high-density urban areas.

- Outdoor Gas-Insulated Substation: Designed for outdoor installation, using gas insulation.

- Indoor Gas-Insulated Substation: Indoor substation with gas-insulated components.

- Composite (Hybrid) Substation: A combination of air-insulated and gas-insulated equipment, offering a balance of reliability and space efficiency.

Distribution substations are essential for ensuring a stable and uninterrupted electricity supply, protecting the grid from faults, and regulating voltage levels to meet consumer demand.

6) Mobile Substation

Mobile substations are specialized, temporary power solutions designed for emergency situations, large construction projects, and maintenance operations. These substations provide a rapid and flexible power supply when permanent substations are unavailable or undergoing repairs. Mounted on trailers or skids, mobile substations can be easily transported and deployed in remote or disaster-affected areas.

Key Features of Mobile Substations:

- Temporary Power Supply: Ideal for construction sites, industrial expansions, and emergency power restoration.

- Quick Deployment: Can be transported and installed rapidly to minimize downtime.

- High Reliability & Safety: Protects against blackouts, fires, natural disasters, and sabotage.

- Low Maintenance: Designed for easy operation and servicing.

- Flexible Voltage Levels: Configured to step up or step down voltage as per specific power requirements.

Mobile substations are essential backup systems that enhance grid resilience and ensure uninterrupted power supply in critical situations.

7) Industrial Substation

Industrial substations, also known as bulk substations, are specialized power distribution facilities that cater exclusively to large industrial consumers. Unlike general distribution substations, these substations are dedicated to supplying high-capacity electricity to industries such as manufacturing plants, steel mills, refineries, chemical plants, and mining operations.

Key Characteristics of Industrial Substations:

- High Power Demand: Designed to handle large electrical loads required for industrial machinery and processes.

- Dedicated Supply: Exclusively serves industrial customers with customized voltage levels.

- Enhanced Power Quality: Ensures stable voltage levels and minimal power fluctuations to support sensitive industrial equipment.

- Efficient Power Distribution: Optimized to reduce transmission losses and improve energy efficiency.

- Specialized Equipment: Includes transformers, switchgear, capacitors, and protective relays tailored for industrial applications.

Industrial substations play a crucial role in ensuring uninterrupted and reliable power supply for large-scale industrial operations, supporting productivity and economic growth.

8) Mining Substation

Mining substations are specialized power distribution units designed to meet the demanding electrical requirements of mining operations. These substations must be built with high safety standards to ensure reliable and hazard-free power distribution in challenging environments, including both surface and underground mines.

Key Features of Mining Substations:

- Robust Design: Built to withstand extreme conditions such as dust, moisture, vibrations, and temperature fluctuations.

- Safety Compliance: Equipped with explosion-proof and fire-resistant components to minimize risks in hazardous mining environments.

- Efficient Power Distribution: Supplies electricity from surface substations to underground mining equipment, including drills, conveyors, and ventilation systems.

- Voltage Control & Protection: Ensures stable voltage levels and includes protective relays to prevent faults and power failures.

- Mobility & Scalability: Some mining substations are modular and transportable, allowing flexibility in expanding mining operations.

Mining substations play a crucial role in maintaining operational efficiency and worker safety, ensuring a continuous and reliable power supply for mining equipment and processes.

Types of Substations Based on Services

Substations are classified based on various factors, one of which is the type of service they provide. The primary types of substations according to their function include:

- Converter Substation

- Switching Substation

- Collector Substation

1). Converter Substation

Converter substations are specialized power facilities designed to modify the frequency or type of electrical power to meet specific transmission and operational needs. They are essential in systems requiring the conversion of alternating current (AC) to direct current (DC) or vice versa.

These substations play a key role in High Voltage Direct Current (HVDC) transmission, where AC power is converted to DC for efficient long-distance transmission and then converted back to AC for distribution.

Additionally, they are used in frequency conversion applications, ensuring compatibility between different electrical systems, such as industrial operations and railway networks.

By facilitating efficient energy transfer, improving grid stability, and integrating renewable energy sources, converter substations are a crucial component of modern power infrastructure.

2). Switching Substation

Switching substations play a crucial role in the power grid by enabling the switching of power lines without altering voltage levels. These substations are strategically located between transmission lines to manage the flow of electricity.

One of their key functions is to isolate and de-energize faulty or damaged equipment, preventing further disruptions to the grid. This enhances the reliability and stability of the electrical system by ensuring that other sections of the grid continue to operate smoothly even when certain components fail.

3). Collector Substation

Collector substations are commonly used in distributed power generation projects, such as wind farms and hydroelectric plants. Their primary function is to gather electricity generated from multiple sources within the project and then deliver it to the grid.

To ensure efficient transmission, the collector substation steps up the voltage of the collected electricity, enabling it to be transmitted over long distances with minimal loss. This is especially important for renewable energy sources, where power is often generated in remote or decentralized locations.

Types of Substations According to Operating Voltage Levels

Substations are categorized based on the voltage levels they handle, and these classifications may vary depending on the region. The primary categories include:

- High Voltage Substations (HV Substations) (11–66 kV)

- Extra High Voltage (EHV) Substations (132–400 kV)

- Ultra-High Voltage (UHV) Substations (Operating >400 kV)

- Direct-Current High Voltage (HVDC) Substations (±250, 400, or 500 kV)

1). High Voltage Substations (HV Substations) (11–66 kV)

High voltage substations, operating within the range of 11 kV to 66 kV, play a crucial role in the electrical power system. They act as intermediaries, converting high-voltage electricity from transmission lines into lower voltages that are suitable for distribution to consumers and businesses.

These substations are vital for efficient power delivery but also pose significant safety concerns due to the high voltages they handle. To mitigate risks, HV substations are typically located in secured, fenced areas with restricted access. They are equipped with numerous safety features, including:

- Grounding systems to prevent electrical hazards.

- Warning signs to alert personnel of potential dangers.

- Personal protective equipment (PPE) for employees working in these high-risk environments.

Such safety measures ensure that HV substations operate securely while providing a reliable power supply.

2). Extra High Voltage (EHV) Substations (132–400 kV)

Extra High Voltage (EHV) substations are critical components of electric power transmission networks. They play a vital role in converting ultra-high voltage electricity from power plants into levels suitable for efficient long-distance transmission via overhead wires. EHV substations also step down extra-high voltages to distribution levels for local use.

These substations utilize heavy-duty equipment designed to handle voltages ranging from 132,000 to 400,000 volts. Key components include:

- High-capacity transformers to step up or step down voltage.

- Circuit breakers to protect the system from faults.

- Switches to control the flow of electricity.

- Instrument transformers for measuring and monitoring voltage and current.

Due to the extremely high voltages involved, EHV substations require strict design considerations, including advanced insulation, lightning protection, and appropriate clearance to ensure safe and reliable operation.

Given their critical role in bulk power transfer and their large size, EHV substations require significant land areas, robust physical protection, constant monitoring, and skilled maintenance. They are essential for the functioning of the transmission grid, ensuring efficient and safe power delivery across vast distances.

3). Ultra-High Voltage (UHV) Substations (Operating >400 kV)

Ultra-High Voltage (UHV) substations operate at exceptional transmission voltages exceeding 400 kV, with some systems reaching up to 1,100 kV. These substations utilize advanced technology to step up voltages from mega-capacity generators to levels suitable for long-distance bulk power transfer via high-voltage overhead lines, often spanning across states.

UHV technology enables the efficient transfer of large quantities of electricity over vast distances to load centers, significantly reducing transmission losses. The key equipment in UHV substations includes:

- Specialized UHV transformers to handle extremely high voltages.

- Reactors to control the flow of power.

- High-voltage circuit breakers for fault protection.

- Instrument transformers for monitoring and measurement.

- Switchgear, using gas or air insulation technologies, for safe and reliable operation.

To ensure safe, reliable, and efficient operation at ultra-high voltage levels, UHV substations rely on sophisticated control systems and automation. These systems incorporate careful design considerations for insulation coordination, clearances, electric field management, noise control, and environmental impacts, ensuring that UHV substations operate optimally while meeting stringent safety and performance standards.

4). Direct-Current High Voltage (HVDC) Substations (±250, 400, or 500 kV)

High Voltage Direct Current (HVDC) transmission systems use power electronics to convert alternating current (AC) electricity into high-voltage direct current (DC). This technology enables the efficient transfer of large blocks of power over long distances, whether via land or subsea cables.

HVDC is particularly effective for bulk power transmission, minimizing transmission losses over vast distances. Key components involved in HVDC substations include:

- Converter transformers to step up or step down voltage levels.

- Thyristor or Voltage Source Converter valves to convert AC to DC.

- Smoothing reactors to reduce voltage fluctuations.

- Harmonic filters to eliminate undesirable frequencies.

- Specialized switchgear designed to manage high DC currents.

HVDC substations typically operate at transmission voltages ranging from ±250 kV to ±500 kV DC, delivered through overhead lines or undersea cables with solid or liquid insulation. Converter stations use air or gas-insulated switchgear that can withstand large DC currents.

To ensure reliable and safe operations, HVDC systems rely on advanced automation and control technologies, alongside careful design considerations for clearances, insulation coordination, and electric field management. The efficiency of HVDC technology reduces transmission losses, especially over long distances, making it a crucial element in modern power grids.

Types of Substations According to Location and Design

Substations are also classified based on their location and design. Here are the main types:

- Outdoor Substation

- Indoor Substation

- Pole-mounted Substation

- Underground Substation

1). Outdoor Substation

Outdoor substations are constructed in open-air environments and are typically designed to house high-voltage equipment, including transformers, circuit breakers, and switchgear. These substations are often referred to by the voltage levels they handle, such as 400KV, 132KV, 220KV, and 66KV substations.

In recent times, gas-insulated substations (GIS) have been introduced for high-voltage systems, offering enhanced reliability and reduced space requirements. These outdoor substations are generally located in areas with ample space and are protected by fencing or other safety measures to ensure secure operation.

2). Indoor Substation

Indoor substations are typically located beneath a covered structure or roof and are designed to operate at lower voltages. These substations are often used for urban environments where space is limited and are commonly referred to by their voltage levels, such as 33KV and 11KV substations.

Since they are housed indoors, these substations are protected from environmental factors like weather, offering increased safety and operational reliability. Indoor substations are compact and designed for easy access to equipment for maintenance and monitoring.

3). Pole-mounted Substation

Pole-mounted substations are typically used for distribution purposes and are built on a structure made up of two, four, or even six or more poles. These substations are commonly found in rural or suburban areas where space is available, and they help distribute power to smaller communities or businesses.

In these substations, distribution transformers are mounted on the poles, along with isolator switches to control the flow of electricity. The single-pole configuration is often referred to as the “H pole,” while four-pole structures are more common for higher capacity needs, typically handling power levels such as 25KVA, 125KVA, and 225KVA.

4). Underground Substation

Underground substations are built beneath the ground, often in densely populated or urban areas where space is limited, and constructing open-air or outdoor substations is not feasible. These substations are designed to minimize land use and avoid the impact of noisy or large structures in crowded environments.

Due to their complex designs, underground substations can accommodate various components such as transformers, switchgear, and protective equipment. These substations typically operate at voltage levels ranging from 34,500/19,920 volts to around 4,160/2,400 volts, depending on the area’s power requirements.

Conclusion

In this post, we have provided an in-depth discussion on the types of substations based on various factors such as application, design, location, service, and operational voltage levels. While there are additional terms like Grid Substations, Town Substations, Traction Substations, and others, these are generally grouped under the categories already described in our detailed guide.

Read Next: