When it comes to electrical safety and circuit protection, understanding the making capacity of a circuit breaker is crucial. For basics, see our guide on circuit breakers. This article delves into the concept of the making capacity of a circuit breaker, its formula, how it relates to the breaking capacity of a breaker, and why knowing these capacities is important for electrical engineers.

What is the Making Capacity of Circuit Breaker?

The making capacity of a circuit breaker refers to the maximum peak current (including the DC offset) that it can safely close onto a fault condition. This value indicates the maximum current a breaker can handle without damage at the moment it is switched on, before any issues arise.

Circuit breakers with high making capacity are essential in high-voltage environments, where sudden spikes in current can occur. This ensures that the breaker does not experience failure when it connects a live circuit.

How Does the Making Capacity of a Circuit Breaker Work?

When a circuit breaker closes, it allows electricity to flow through the circuit. If a short circuit occurs, the making capacity circuit breaker must immediately handle this excessive current flow. It reflects the peak fault current a breaker can safely withstand at the instant of closing onto a live circuit.

For instance, if a breaker’s peak closing current is rated at 25 kA (kiloamperes), it can safely withstand a short-circuit surge of 25 kA at the instant of being switched on.

The Difference Between Making Capacity and Breaking Capacity

It’s essential not to confuse the making capacity of a circuit breaker with its breaking capacity. While the making capacity refers to the ability to safely close and withstand the initial surge of current, the breaking capacity circuit breaker indicates the maximum amount of fault current that the breaker can safely interrupt once the fault has occurred.

- Making Capacity: The breaker’s ability to handle the initial current surge when it’s switched on.

- Breaking Capacity: The maximum fault current the breaker can interrupt once a short circuit happens.

Learn more: Breaking Capacity of Circuit Breaker: Explained with Example

Mathematical Relation Between Making and Breaking Capacity

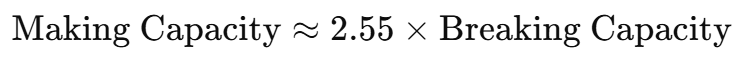

The making capacity of a circuit breaker is typically 2.55 times higher than its breaking capacity. This is due to the different electrical conditions the breaker faces during closure and during fault interruption. These values are key parameters in circuit breaker ratings, ensuring the device performs reliably under fault conditions.

- Making Capacity: Represents the peak current surge at the moment the breaker is first closed on fault.

- Breaking Capacity: Represents the maximum fault current the breaker can interrupt once the fault has occurred.

The relationship can be expressed as:

Making Capacity≈2.55×Breaking Capacity

For example, if a circuit breaker has a breaking capacity of 25 kA, its making capacity would typically be around:

Making Capacity=2.55×25 kA=63.75 kA

This means the breaker can safely handle a surge current of up to 63.75 kA when first closed on fault condition, ensuring that it can withstand the initial high-current conditions without failure.

Factors Affecting the Making Capacity of Circuit Breakers

Several factors influence a breaker’s peak current rating during closure, including:

- Voltage Level: Higher voltage systems typically require breakers with a higher making capacity. Learn more in our guide on Classification of Voltage Levels.

- Type of Circuit: Different circuits (industrial, commercial, residential) require breakers with varying making capacities.

- Short-Circuit Protection: A breaker’s making capacity must be sufficient to handle fault conditions at the moment it is turned on. → Learn more about fault current behavior in our article on overcurrent protection,

- Breaker Design: The physical design and technology used in the breaker, such as whether it’s a vacuum, SF6, or air circuit breaker, will affect its making capacity.

Importance of Correctly Sizing the Making Capacity

Ensuring the breaker’s making capacity aligns with system requirements is essential for avoiding failure during initial fault conditions.

- Safety: If the breaker’s making capacity is too low, it could fail to handle a short-circuit condition, resulting in damage to the electrical system or even fires.

- Longevity: Proper sizing ensures that the breaker operates optimally and doesn’t experience unnecessary wear and tear.

- Compliance: Regulatory standards often dictate the minimum making capacity requirements for various systems to ensure safety.

Explore the types of ACBs where making capacity is critical.

Conclusion

Breakers must meet international standards and pass testing to validate their rated capacities. You can read more about this in our guide on circuit breaker testing methods.

In summary, having a clear understanding of the making capacity of circuit breaker is essential for maintaining the safety, stability, and long-term reliability of any electrical installation. This capacity defines how much peak current a breaker can handle at the moment of closure onto a fault, ensuring that it doesn’t fail under sudden electrical stress.

On the other hand, the breaking capacity refers to a breaker’s ability to interrupt sustained fault current once a fault is established. By appreciating the functional distinction between these two ratings and the design factors that influence them, electrical engineers and system designers can make smarter, code-compliant decisions that protect equipment, personnel, and system performance over time.

Key Takeaways:

- Making Capacity: The highest current a breaker can safely handle at the instant of closing onto a fault.

- Breaking Capacity: The maximum fault current the breaker can interrupt once the fault has occurred.

- Mathematical Relation: Making Capacity ≈ 2.55 × Breaking Capacity (as per IEC standard IEC 60947-2 for low-voltage circuit breakers and IEC 62271-100 for high-voltage circuit breakers).

- In high-voltage and industrial systems, always account for the making capacity of circuit breaker during selection.

- Correctly sizing the making current of a circuit breaker helps prevent damage and extends system lifespan.

FAQs

The peak making current is the maximum instantaneous current, including the DC offset, that a circuit breaker can safely close onto during a fault condition. It is typically 2.5 to 2.55 times the symmetrical breaking capacity, as per IEC standards.

The making capacity is higher because it must handle the asymmetrical peak current that occurs at the instant of contact closure during a short circuit. This surge includes both the AC and DC components, making it more severe than the steady-state fault current the breaker interrupts.

According to IEC standards, the making capacity is typically 2.55 times the symmetrical breaking capacity. This ratio considers the asymmetrical peak current that appears immediately after a fault begins.

Yes. Vacuum, SF6, air, and oil circuit breakers each have different arc-quenching characteristics, which affect their making and breaking capacities. Vacuum circuit breakers, for example, typically have higher making capacity due to better arc control.

If fault current exceeds the breaker’s making capacity, it may fail to close safely, causing contact damage, arcing, or even explosive failure. This can lead to equipment damage and pose serious safety risks.

Related Article: