What is Pole in Electric Motor? Learn how motor poles affect speed, torque, and performance in electric motors. A simple guide to understand motor poles and their significance.

When we talk about electric motors, one of the most important concepts to understand is the motor pole. But what is pole in electric motor exactly? In simple terms, motor poles are magnetic poles formed by the windings in the stator of the motor. The number of poles in motor—typically 2, 4, 6, or 8—directly affects its speed and torque, playing a crucial role in determining the motor’s performance characteristics.

What is Motor Pole and How Does It Work?

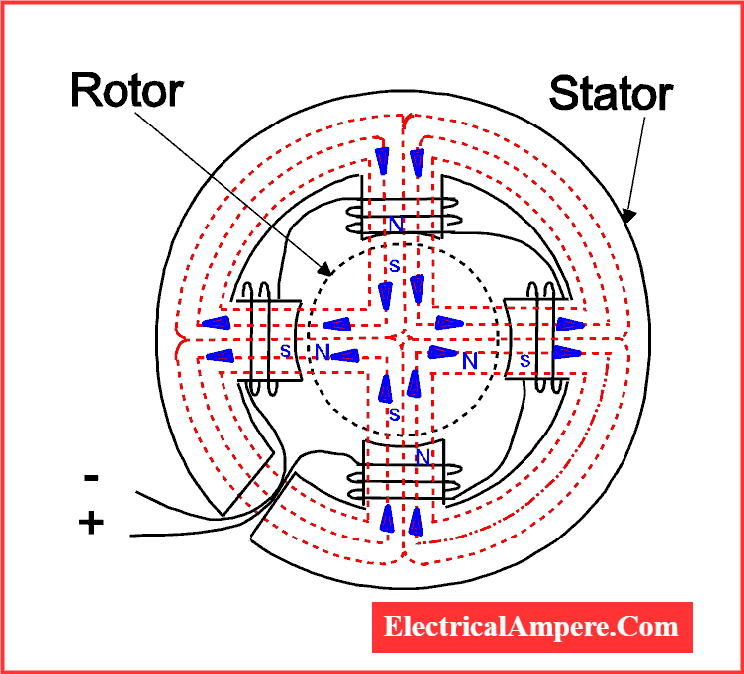

The electric motor pole refers to the magnetic pole generated in the stator winding of a motor. When current passes through the stator windings, magnetic fields are created. These magnetic fields interact with the magnetic field of the rotor, leading to rotation. This rotation is the basic working principle of any electric motor.

The motor poles are responsible for creating the magnetic field required to initiate and maintain this rotation. More specifically, the number of poles in a motor determines the synchronous speed — the higher the number of poles, the lower the speed, and vice versa.

Relationship Between Motor Poles and Synchronous Speed

One of the most important aspects of understanding what is pole in motor is knowing how it relates to synchronous speed. Synchronous speed is the speed at which the magnetic field rotates in an AC motor.

Formula:

Synchronous Speed (Ns)=120×f/P

Where:

- Ns = Synchronous speed in RPM

- f = Supply frequency in Hz

- P = Number of motor poles

Explanation:

As the number of motor poles increases, the synchronous speed of the motor decreases. For example:

- A 2-pole motor on a 60 Hz supply:

Ns=120×60/2=3600 RPM - A 4-pole motor on the same supply:

Ns=120×60/4=1800 RPM

This means that motor poles directly control how fast the motor’s rotor will turn. Choosing the right number of poles is essential for designing motors for specific applications, whether high-speed or high-torque.

Relationship Between Poles and Speed in DC Motor

In DC motors, the speed is inversely proportional to the number of poles, but not as directly as in AC motors. The speed of a DC motor depends on factors including the number of poles, armature current, field flux, and supply voltage.

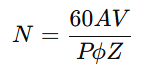

DC Motor Speed Formula:

Where:

- N = Speed of the motor in RPM

- A = Number of parallel paths in the armature

- V = Applied voltage

- P = Number of poles (motor poles)

- ϕ = Flux per pole

- Z= Total number of armature conductors

Explanation:

- As the number of poles (P) increases, the speed (N) decreases (if all other factors remain constant).

- More poles result in more magnetic interactions per rotation, slowing down the motor.

- Fewer poles mean faster motor speed, but they require better commutation and mechanical balancing.

Example:

- A 2-pole DC motor will generally rotate faster than a 4-pole DC motor when powered with the same voltage and load conditions.

The Structure and Function of Poles in Motor

At their core, motor poles are built with robust steel structures, often wrapped with high-conductivity copper coils around iron cores. These components are electrically insulated for protection. When current flows through the coils, a magnetic field is generated around the core.

This magnetic field interacts with the rotor’s field, causing movement. The orientation, strength, and geometry of the motor pole significantly affect how efficiently the motor operates. Therefore, the physical design and materials used in electric motor poles are crucial for performance.

Magnetic Interaction of Electric Motor Poles

The interaction between the stator poles and the rotor field creates the torque that turns the rotor. The motor pole count and their arrangement influence critical aspects like rotational speed and torque.

For example:

- Motors with fewer poles rotate faster but produce less torque.

- Motors with more poles rotate slower but generate higher torque.

Thus, engineers carefully design motor poles to balance these forces based on the application.

A Brief History of Motor Poles

The concept of motor poles has evolved over time. Initially, motors used basic iron cores and very basic winding systems. The discovery of electromagnetism by Michael Faraday in 1831 changed everything, allowing for better field control using electromagnetic coils.

Over the years, innovations in materials, like high-purity copper and corrosion-resistant steel, made electric motor poles more efficient, durable, and suitable for a wide range of applications.

Types of Motor Poles and Their Applications

Understanding the types of motor poles helps us determine which motors are best suited for particular tasks:

1. Salient Poles

- Found in: DC motors and older AC motors

- Characteristics: High torque at low speeds

- Applications: Automotive starter motors, cranes, locomotives

2. Non-salient Poles (Embedded Poles)

- Found in: Modern AC motors

- Characteristics: Smooth and efficient operation at higher speeds

- Applications: Industrial machinery, HVAC systems, home appliances

3. Single-phase Poles

- Characteristics: Produce pulsating magnetic fields

- Applications: Fans, water pumps, basic home appliances

4. Multi-phase Poles (e.g., Three-phase)

- Characteristics: Produce rotating magnetic fields, ideal for high efficiency

- Applications: Industrial motors, electric vehicles, heavy-duty pumps

Key Material Considerations for Motor Poles

The design and performance of a motor pole depend heavily on the materials used. The three critical factors are:

Strength

Poles must endure stress and magnetic forces during operation. High-strength steel ensures structural integrity under these conditions.

Conductivity

Copper windings within the poles must have excellent electrical conductivity. This improves magnetic field strength and enhances motor performance.

Corrosion Resistance

Even though motor poles are often enclosed, they may still be exposed to humidity or corrosive environments. Using corrosion-resistant materials or coatings ensures long-term reliability.

From Fabrication to Maintenance: The Lifecycle of a Motor Pole

Fabrication

- Starts with selecting high-grade steel

- Advanced shaping techniques like laser cutting and forging

- Coils are wrapped with copper and insulated

Installation

- Requires precise setup, grounding, and anchoring

- Heavy machinery may be needed for positioning

- Safety protocols must be strictly followed

Maintenance

- Includes regular inspections for cracks, corrosion, and insulation wear

- Tools like ultrasound and thermal imaging aid in diagnostics

- Repairs may involve welding, reinforcement, or insulation replacement

Future of Motor Poles: Innovation and Sustainability

In the modern era, motor poles are being integrated with sensors and smart systems. These can:

- Monitor performance

- Detect faults in real-time

- Optimize energy use

Environmental Innovations

Materials like bamboo composites, recycled metals, and bio-inspired polymers are being explored to reduce the carbon footprint of electric motor poles.

Advanced Materials

- Nanocomposites for better strength-to-weight ratios

- Self-healing and corrosion-resistant coatings

- Self-cleaning surfaces for longer lifespan and reduced maintenance

Conclusion

So, what is pole in motor and why does it matter? Simply put, motor poles are the important part inside every electric motor. Understanding the function, types, and future of motor poles not only enhances our knowledge of motor design but also prepares us for the smarter, more sustainable electric motors of tomorrow.

Read Next: