Reliable power transmission starts with understanding underground cable (UG Cable) construction. These cables are designed to safely carry electrical current while withstanding environmental and mechanical stresses.

In this article, we will explain the construction of underground cables, including cores, insulation, metallic sheath, armoring, and protective layers. Diagrams are provided to help visualize each part and understand its function. Whether you are selecting the right cable for a project or learning about its components, this guide offers a clear and easy-to-follow overview.

Overview and Selection of Underground Cables

Underground Cable (UG Cable) comprise one or more conductors covered with insulation and then protected with a cover.

The right cable type is crucial for a reliable electrical power transmission system. The choice of cable depends on the working voltage and service requirement. For instance, for a 6.6 kV earth system, choosing the 6.6 kV(E) (E-earth ) is essential.

Key Considerations for Choosing Underground Cables

When selecting an Underground Cable (UG Cable), consider the following requirement.

- Type of conductors– tinned stranded copper/ aluminum

- Conductor size – Select the cable as per the desired load requirement.

- The thickness of the cable Insulation– The thickness of the insulation increases with an increase in the cable’s working voltage.

- Sheath – The cable sheath is responsible for providing mechanical protection to the cable, shielding it from any potential damage.

- Cable Materials -The cable materials should protect the cable from chemical and physical damage.

Construction of Underground Power Cables

Now, let’s discuss the construction of underground cables.

Underground cables are typically constructed with one or more conductors wrapped in insulating materials to provide electrical insulation. The cable is then given another layer of insulation and finally protected by a shield to ensure safety against mechanical damage.

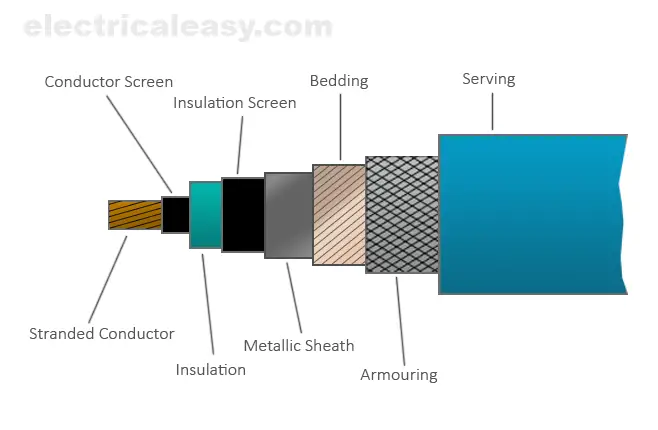

UG Cable Diagram: Layers of Underground Cable Construction

The diagram below provides an overview of the construction of an Underground Cable (UG Cable).

Image courtesy: electricaleasy

UG Cable Parts and Layers

Conductor or Core

An Underground Cable (UG Cable) may have one or more cores depending on its intended service. For example, a 3-conductor cable is used for a 3-phase 3-wire electrical system, while a 3 and 1/2 core cable is used for a 3-phase 4-wire system.

A cable’s conductors can either be solid or stranded. The stranded conductor reduces the skin effect and proximity effect and offers more cable flexibility. The conductor can be made of tinned copper or aluminum. The cable’s current carrying capacity depends on the cable’s size. The larger the conductor’s cross-sectional area, the greater its capacity to carry current.

Medium voltage conductors are typically used from 35mm2 to 1000mm2 and are usually compacted stranded or solid.

Aluminum conductors are ideal for long-distance medium voltage distribution networks that require extensive cabling. On the other hand, copper cables are used for shorter links in substations and industrial installations where higher power transmission is desired.

Conductor Screen

Conductor screening is commonly employed in MV and HV underground cables to maintain a uniform electric field and minimize electrostatic stresses. It typically consists of a semi-conducting tape or an extruded layer of a semi-conductive cross-linked compound, usually less than 1.0mm.

Insulation

The cable conductors carry the live electrical phases and must be insulated to prevent short circuits. Therefore, insulation of suitable thickness is provided around the core of the conductors.

The cable’s working voltage determines the insulation thickness around a conductor. The cable’s insulation must comply with the standard requirements and withstand the electrical potential during rated and transient operating conditions.

See the table on cable insulation thickness.

| U0 (kV) phase-to-phase voltage | U (kV) phase-to-phase voltage | Um (kV) highest permissible voltage | BIL (kV) basic impulse level | Insulation thickness (mm) – Minimum Average |

| 3.8 | 6.6 | 7.2 | 60 | 2.5 – 3.2 |

| 6.35 | 11 | 12 | 95 | 3.4 |

| 8.7 | 15 | 17.5 | 120 | 4.5 |

| 12.7 | 20 | 24 | 144 | 5.5 |

| 19 | 33 | 36 | 194 | 8.0 |

The commonly used materials for cable insulation include impregnated paper, varnished cambric, rubber, mineral compounds, VIR (Vulcanized India Rubber), PVC (polyvinyl chloride), and XLPE (cross-linked polyethylene).

XLPE (Cross-linked Polyethylene) and EPR(Ethylene Propene Rubber) are two main types of insulation material used in medium-voltage underground cables.

Insulation screen

A layer of semi-conductive material is applied over the insulation to reduce electrical stress on the cable.

Metallic Sheath in UG Cable

The cable is exposed to the surrounding environment, which may contain damaging liquids such as acids and alkalis in the soil. This can cause damage to the cable. A sheath made of lead or aluminum is provided around the insulator to protect the cable.

The metallic sheath does the following functions.

- When an electric cable is charged, a lumped capacitor is created between the conductor’s core and the sheath. The sheath serves as the second electrode of the capacitor, and when the current flows through the conductor, an electric field is generated. The sheath is grounded to eliminate the electric field, resulting in a zero electric field outside the cable.

- The sheath also acts as a radial barrier, preventing humidity from entering the cable insulation system. An electric field and humidity can cause water-treeing, which deteriorates cable insulation and can lead to failure.

Bedding

Protecting the metallic sheath against corrosion and mechanical damage due to armoring is essential. A layer of bedding consisting of fibrous material, such as jute or hessian tape, is applied over the metallic sheath.

Armoring

The cable is armored to prevent mechanical damage during installation and operation. The armor layer comprises one or two galvanized steel wire or tape applied over the bedding layer.

Serving Layer in UG Cable

A second layer of insulation is added over the armor to protect the steel from atmospheric contaminants. It can be made of materials like Jute, Hessian, or thermoplastic compounds like PVC.

UG Cable Parts: Summary Table

| Parts | Function | Composition |

| Conductor | It carries the current through it under normal, overload, and short-circuit conditions. |

S<1000mm² (copper or aluminum) Compacted round stranded conductors S<400mm² (aluminum) Round solid conductors |

| Internal semiconductor |

1. Prevents concentration of the electric field at the interface between insulation and internal semi-conductor 2. Ensures close contact with insulation and smooths the electric field at the conductor |

XLPE semi-conducting shield |

| Insulation | To withstand various voltage field stresses during the cable service life: rated voltage, lightning overvoltage, switching overvoltage | XLPE insulation; internal and external semi-conducting layers co-extruded within the same head |

| External semiconductor | Ensures close contact between insulation and screen; prevents concentration of electric field at the interface | XLPE semi-conducting shield |

| Metallic screen | Provides electric screen (no electric field outside cable), radial waterproofing, active conductor for capacitive and zero-sequence short-circuit current, mechanical protection | Extruded lead alloy, or copper wire screen (with optional helical equalizing tape), welded aluminum screen bonded to PE jacket, combination of copper wires and lead sheath, copper tape screens and wire armoring, copper foil laminate |

| Outer protective sheath | Insulates metallic screen from surrounding medium, protects metallic screen from corrosion, contributes to mechanical protection, reduces fire propagation | Insulating sheath; possibility of semi-conducting layer for dielectric tests, Polyethylene jacket, PVC jacket, HFFR jacket |

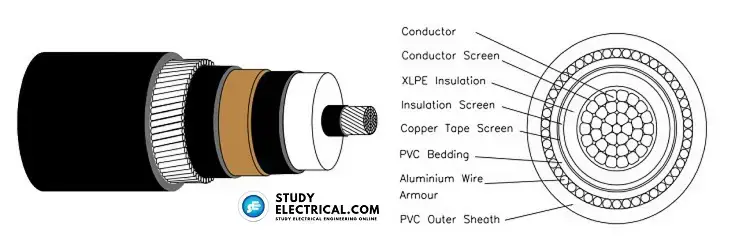

Construction Details of Single Core XLPE Insulated Armoured PVC Sheath Underground Cable

Image courtesy: studyelectrical

| Parts of the Underground Cable | Details |

| Conductor | Plain circular compacted stranded copper or aluminum conductor to IEC 60228 class 2. |

| Conductor Screen | An extruded layer of semiconductive compound. |

| Insulation | XLPE (cross-linked polyethylene) is rated at 90°C temperatures. |

| Insulation Screen | 1. Non-metallic part – An extruded layer of semiconductive compound. 2. Metallic part – Copper tape screen (SCT). |

| Armour | Aluminum wires applied helically over the PVC bedding for mechanical protection. |

| Outer Sheath | Made of PVC or PE, it protects the cable from moisture, chemicals, and other environmental effects. |

Conclusion

This article explained the construction of Underground Cable (UG Cable), along with their key parts, helping readers understand their structure and choose the right cable for specific applications.

Reference- Types of Underground Cables- www.electrricalvolt.com

FAQs

The bedding layer is provided above the metallic sheath to protect it from corrosion and mechanical damage caused by the armoring.

An UG cable is an insulated electrical cable designed to safely transmit power underground while withstanding environmental and mechanical stresses. It usually includes a conductor, insulation, metallic sheath, armoring, and protective layers.

The primary parts include: conductor/core, conductor screen, insulation, insulation screen, metallic sheath, bedding, armoring, and the outer protective sheath. Each layer has a specific role in electrical insulation, mechanical protection, and longevity.

Common insulation materials include XLPE (cross-linked polyethylene), EPR (Ethylene Propene Rubber), PVC, impregnated paper, and rubber. XLPE and EPR are preferred for medium-voltage UG cables.

Armoring protects the cable from mechanical damage during installation and operation. It usually consists of galvanized steel wires or tapes applied over the bedding layer.

Related Articles: