In any power distribution system, the shackle insulator is indispensable because it prevents unwanted current flow to the supporting structures. Without proper insulators, electricity could leak into poles, towers, or the ground, causing serious safety hazards.

Among the types of insulators in transmission lines, the shackle insulator—sometimes called a spool insulator—is one of the simplest yet most effective for low-voltage distribution lines.

This guide covers everything about shackle type insulators—their construction, types, working, diagram, applications, and how they differ from other insulators on transmission lines.

What is a Shackle Insulator?

A shackle insulator is a small cylindrical insulator used mainly in overhead distribution lines up to 11 kV. Unlike large suspension type insulators used in high-voltage transmission, shackle insulators are compact, cost-effective, and ideal for short spans and angle poles.

They are commonly installed on LT (low-tension) lines in rural and urban power networks.

- Other names: Spool insulator, distribution line insulator

- Voltage range: Suitable up to 11 kV (sometimes used up to 33 kV in rare cases)

- Mounting: Can be fixed either horizontally or vertically on poles and cross-arms

Because of their small size, shackle insulators are particularly effective at turning points of distribution lines, where mechanical stress is higher.

Construction of Shackle Type Insulator

The construction of a shackle insulator is simple yet robust, making it durable even in harsh environments.

- Material: Usually made of porcelain insulator material or toughened glass, both offering excellent electrical insulation and mechanical strength.

- Shape: Cylindrical or spool-like with a groove around the circumference to hold conductors securely.

- Mounting hardware: Fixed to the pole or cross-arm with the help of a bolt and metal strap.

This design allows it to handle both mechanical strain and electrical insulation effectively.

Working Principle of Shackle Insulator

The working of a shackle insulator relies on electrical isolation and mechanical support.

- The conductor is placed in the groove of the insulator.

- A binding wire or clamp secures the conductor.

- The insulator prevents leakage current, ensuring electricity flows through the conductor only.

- The insulator bears the mechanical tension of the line, especially at angular positions.

Thus, the shackle type insulator acts both as an electrical insulator and a strain insulator in low-voltage lines.

Types of Shackle Insulator

Shackle type insulators are classified based on their material, size, and application. The main types are:

1. Porcelain Shackle Insulator

- The most widely used type in distribution lines.

- Made from glazed porcelain, which provides excellent insulation and weather resistance.

- Long service life and reliable under outdoor conditions.

2. Glass Shackle Insulator

- Made of toughened or annealed glass.

- Offers good electrical strength but is less common compared to porcelain.

- Can shatter under mechanical stress, so mostly used in specific distribution setups.

3. Polymer (Composite) Shackle Insulator (modern type)

- Made using polymeric materials like silicone rubber.

- Lightweight and resistant to vandalism.

- Increasingly used in areas where porcelain insulators are prone to damage.

4. Based on Mounting Position

- Horizontal mounting type: Fixed flat on cross-arms.

- Vertical mounting type: Installed upright on poles.

Each type has its advantages, and the selection depends on line voltage, mechanical stress, and environmental conditions.

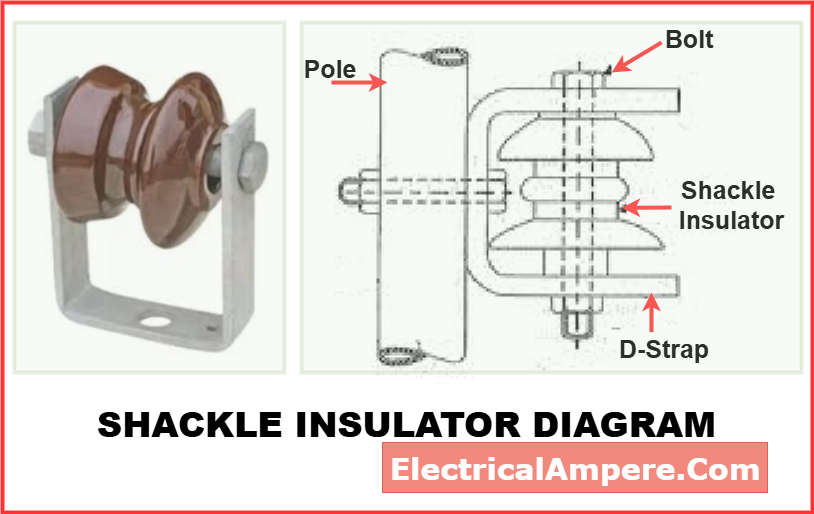

Shackle Insulator Diagram

Below is a typical representation of a shackle insulator diagram:

- Groove: Holds the conductor in place.

- Binding wire: Tightly secures the conductor.

- Porcelain/glass body: Provides insulation.

- Metal strap or bolt: Fixes the insulator to the cross-arm or pole.

The diagram helps visualize how conductors are supported and insulated on distribution poles.

Applications of Shackle Insulator

Shackle insulators have several practical uses in power distribution systems:

- Widely used in low-voltage distribution lines (LT lines up to 11 kV).

- Common at line junctions or angular points, where mechanical stress is higher.

- Used in straight runs to support and insulate conductors.

- Employed in rural electrification networks due to their low cost and easy availability.

- Preferred in compact urban distribution systems where space is limited.

Advantages & Disadvantages of Shackle Type Insulator

Advantages

- Cost-effective compared to larger insulators.

- Compact and lightweight, making installation simple.

- Can be fixed horizontally or vertically as needed.

- Provides reliable insulation in low-voltage distribution.

- Withstands mechanical strain effectively.

- Made of weather-resistant porcelain, ensuring long service life.

Disadvantages

- Not suitable for high-voltage transmission lines.

- Less efficient compared to suspension insulators in long spans.

- Can crack under severe mechanical stress if not properly maintained.

Difference Between Shackle Insulator and Suspension Insulator

| Feature | Shackle Insulator | Suspension Insulator |

| Voltage Range | Up to 11 kV (occasionally 33 kV) | 11 kV to 765 kV |

| Application | Low-voltage distribution lines | High-voltage transmission lines |

| Design | Small, spool-like | String of porcelain/glass discs |

| Mounting | Fixed on poles/cross-arms | Hung from cross-arms |

| Role | Insulation + strain handling | Mainly insulation for long spans |

This comparison shows that shackle type insulators serve distribution networks, while suspension insulators dominate high-voltage transmission.

Relation to Other Types of Insulators

- Pin type insulator: Common for 11 kV–33 kV overhead lines.

- Strain insulator: Used at dead-ends and sharp turns in high-voltage lines.

- Suspension insulator: Ideal for long spans and high voltages.

- Shackle insulator: Economical solution for low-tension distribution.

Together, these insulator types in transmission lines ensure safe and reliable electricity supply.

Conclusion

The shackle insulator is a small but crucial component in low-voltage distribution systems. It insulates the conductor from the pole while withstanding mechanical strain, especially at line angles and junctions.

- For LT networks up to 11 kV, shackle insulators are cost-effective and reliable.

- For high-voltage transmission lines, other insulator types like suspension or strain insulators are better suited.

With different types of shackle insulators—porcelain, glass, and polymer—utilities can choose the most suitable one based on environmental and operational needs.

The shackle type insulator plays a key role in distribution systems, helping deliver power safely to homes and industries.

For a complete overview, check out our Types of Insulators in Transmission Line guide.

Related Articles:

- What is Disc Insulator: Its Types & Applications

- Stay Insulator: Definition,Types, Working Principle, Material

- What is Post Insulator? Types & Applications

- Strain Insulator- Definition, Construction, Working, Types, Applications

- Pin Type Insulator: Construction, Uses, Diagram & Advantages

- Suspension Type Insulator – Diagram, Types & Advantages

- Conductors and Insulators – Examples, Definition

- Types of Insulators Used in Overhead Transmission Line