An oil circuit breaker is a type of circuit breaker that uses oil as a dielectric or insulating medium to extinguish the electrical arc. The breaker’s contacts are separated within an insulating oil. When a fault occurs in the system, the circuit breaker’s contacts are opened under the insulating oil, creating an arc between them. The heat generated by the arc is dissipated in the surrounding oil.

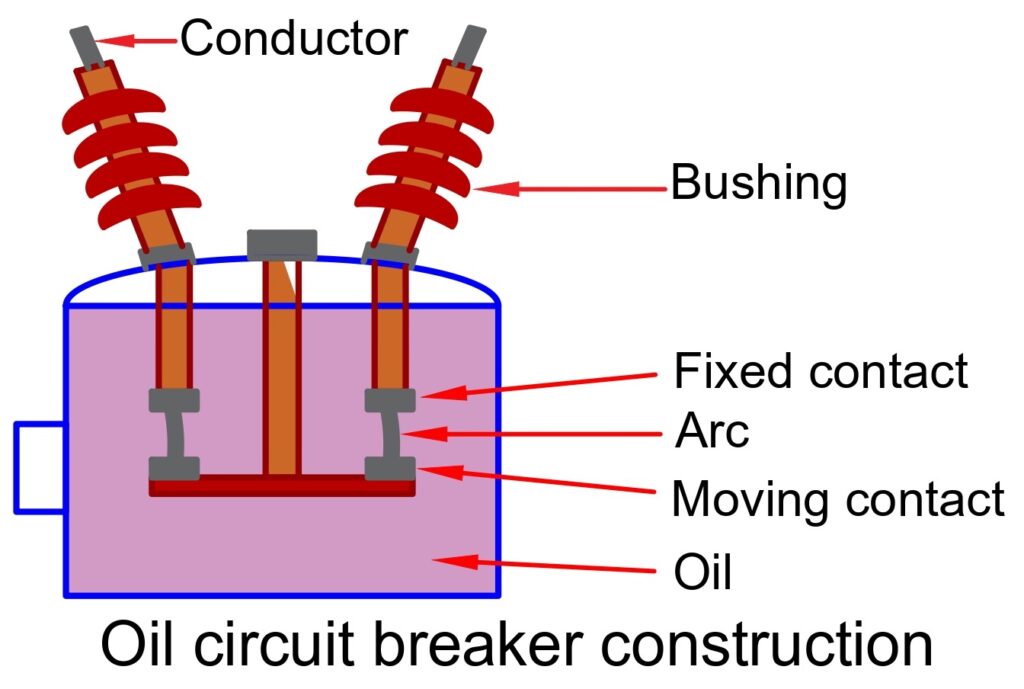

Construction of Oil Circuit Breaker

The oil circuit breakers are quite simple in their construction. It comprises current-carrying contacts enclosed in a sturdy, weather-tight tank of earth metal. The tank is then filled with transformer oil, acting as an arc-extinguishing medium and an insulator between the live part and the earth.

Air is filled at the top of the oil tank, which provides a cushion to control the displaced oil when gas is formed around the arc. It also absorbs the mechanical shock of the upward movement of oil. The breaker tank is securely bolted to carry out the vibrations caused by interrupting high currents. The oil circuit breaker (OCB) consists of a gas outlet fitted in the tank cover for removing gases.

Working Principle of Oil Circuit Breaker

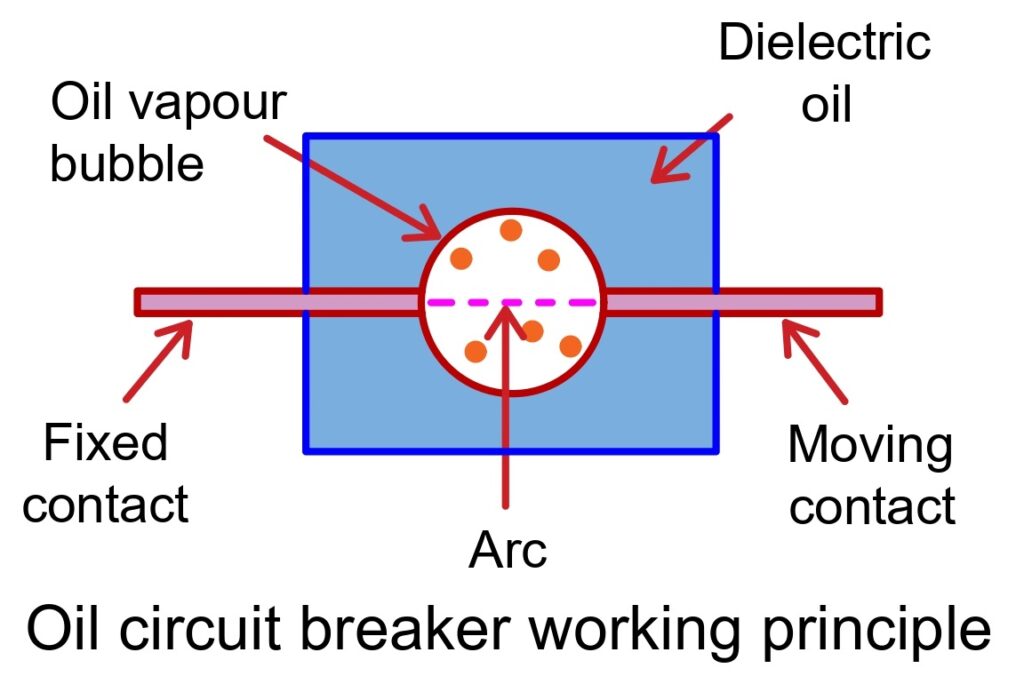

Under normal operating conditions, the oil circuit breaker’s contact closes the carrying current. However, when a fault occurs in the system, the contacts of the breaker move apart, creating an arc between them.

As a result of the electrical arc, a significant amount of heat is produced, which causes the surrounding oil to vaporize into gas at a very high temperature. The released gas then surrounds the arc, causing it to grow explosively and violently displace the oil. The arc is only extinguished when the distance between the fixed and moving contact reaches a critical value, which is dependent on both the arc current and recovery voltage.

The oil circuit breakers are a cost-effective and reliable device. It doesn’t require specialized equipment to control the arc the moving contact creates. However, using oil as the medium for arc quenching has both advantages and disadvantages.

Types of Oil Circuit Breaker

Oil circuit breakers are classified into two categories.

Bulk Oil Circuit Breaker

Bulk oil circuit breakers, or BOCBs, are circuit breakers that utilize oil as both an arc quenching and insulating medium between the current-carrying contacts and the earthed parts of the breaker. The oil used in BOCBs is the same type used to insulate transformers.

To learn more about its working, construction, and advantages, read our full guide on Bulk Oil Circuit Breaker (BOCB).

Minimum Oil Circuit Breaker

These circuit breakers use oil as the medium to break the electrical current. The minimum oil circuit breakers (MOCB) have the interrupting unit placed in an insulating chamber at the live potential. The MOCB is designed to use less oil and is called a “minimum oil circuit breaker.”

To learn more about its working, construction, and advantages, read our full guide on Minimum Oil Circuit Breaker (MOCB).

Advantages of Oil as an Arc Quenching

- The oil provides insulation between contacts by maintaining high dielectric strength even after the arc is extinguished.

- The oil provides a small gap between the conductors and the earth components.

- The oil has good cooling properties and a high diffusion rate of hydrogen gas that forms in the tank.

Disadvantages of Oil as an Arc Quenching

- The oil used in the circuit breakers is flammable, posing a fire hazard.

- It is important to note that there is a potential danger of an explosive mixture forming when combined with air.

- Due to the decomposition of oil in the arc, carbon particles are generated, which pollute the oil and hence decrease its dielectric strength.

Maintenance of Oil Circuit Breaker

In case of a short-circuit current, a circuit breaker might experience burnt contacts due to arcing. Additionally, the dielectric oil in the contact area can get carbonized, which leads to a loss of its dielectric strength. This reduces the breaker’s breaking capacity. Hence, it is crucial to maintain oil circuit breakers by regularly checking and replacing the oil and contacts.

Applications

Oil circuit breakers are used in high-voltage applications such as power grids, substations, powerlines, and transmission and distribution systems with voltage ratings of up to 220 kV.

Key Takeaways

Oil circuit breakers are essential components in electrical systems, especially in medium- to high-voltage networks. Here’s a quick recap:

- Medium for Interruption: Use insulating oil for both arc quenching and dielectric insulation.

- Application: Commonly used in power grids, substations, and distribution networks up to 220 kV.

- Maintenance Needs: Require regular oil checks and contact cleaning/replacement.

- Modern Relevance: While newer technologies like SF₆ and vacuum breakers are more common today, oil circuit breakers are still widely in service.

- Key Takeaway: Knowing how they work and are maintained helps ensure system reliability and safety.

Related Articles: