Discover how eddy current is produced with simple explanations and real-world examples. Learn how electromagnetic induction and eddy current loss affect motors, brakes, and more.

Have you seen a metal pendulum slow down near a magnet? That’s because of eddy currents. Learning how eddy current is produced helps us connect physics to real-life tools like brakes, meters, and induction stoves.

In this article, we’ll explore how eddy currents are produced, the physics behind it, examples, and important related concepts.

What Are Eddy Currents?

Eddy currents are loops of electric current induced within conductors by a changing magnetic field. These currents flow in closed loops and generate their own magnetic fields, which often oppose the original magnetic field.

How Eddy Currents Are Produced

The Basic Principle: Electromagnetic Induction

Eddy currents are generated when a conductor is exposed to a changing magnetic field. This phenomenon is explained by Faraday’s Law of Electromagnetic Induction, which states that a varying magnetic flux induces an electromotive force (EMF) within the conductor.

Here’s how it works step-by-step:

- When either a magnet moves near a metal conductor or the conductor moves through a magnetic field, the magnetic flux experienced by the conductor changes.

- This change in magnetic flux causes electrons inside the conductor to move, creating circular loops of current called eddy currents.

- These currents flow in closed loops within the conductor, generating their own magnetic fields.

- According to Lenz’s Law, the magnetic field created by eddy currents opposes the change that caused them, resulting in a resistive force against the motion.

This process clearly illustrates how eddy current is generated in conductors like copper or aluminum when exposed to varying magnetic fields in motion-sensitive systems or dynamic electromagnetic environments.

Eddy currents are induced under these conditions:

- When a metallic object moves through a magnetic field.

- When the magnetic field near a stationary conductor changes over time.

- When a magnet moves near a stationary conductor like copper or aluminum.

Because eddy currents oppose the motion or change in the magnetic field, they can be used for applications like electromagnetic braking and metal detection.

Real-Life Example: Metal Plate and Magnet

To visualize this, imagine a metal plate moving into a varying magnetic field. Inside the metal, small circular arrows show the flow of eddy currents. These currents flow perpendicular to the magnetic field lines.

Because these eddy currents generate their own magnetic fields that oppose the original change, the plate experiences resistance to motion. This effect perfectly illustrates Lenz’s Law.

That’s why you see the plate slow down — the eddy currents push back against its movement.

Such setups are often used to demonstrate eddy current examples in daily life, like magnetic damping in amusement park rides or automatic doors.

Eddy Current Formula

To calculate eddy currents, we start with the induced electromotive force (EMF).

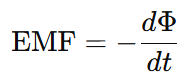

Induced EMF Formula (Faraday’s Law)

Where:

- Φ = Magnetic flux (in Weber)

- t= Time (in seconds)

- EMF = Induced voltage (in volts)

This means the induced EMF depends on the rate of change of magnetic flux.

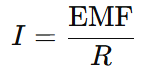

Ohm’s Law for Eddy Current:

Where:

- I = Eddy current (in amperes)

- R = Resistance of the conductor (in ohms)

Simply put, a faster change in magnetic flux or a lower resistance leads to stronger eddy currents.

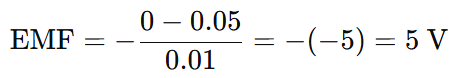

Numerical Example: Let’s consider a case where the magnetic flux in a metal plate changes from 0.05 Wb to 0 Wb in 0.01 seconds, and the resistance of the path is 2 ohms.

Step 1: Calculate EMF

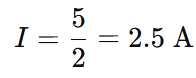

Step 2: Calculate Eddy Current

So, the induced eddy current is 2.5 amperes.

Eddy Current Loss

As eddy currents flow through a conductor, they generate heat. This loss of energy is called eddy current loss, which can reduce the efficiency of devices like transformers and motors. Laminated cores and special materials are often used to minimize this loss by restricting the paths available for eddy currents.

So, what causes eddy current loss? It’s primarily the induced circular currents within conductive material due to changing magnetic fields. These circulating currents generate heat as they pass through the metal’s resistance.

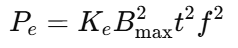

This loss can be estimated using the formula:

Eddy current loss formula:

Where:

- Pe = Eddy current power loss (Watts)

- Ke = Constant depending on material properties

- Bmax = Maximum flux density (Tesla)

- t= Thickness of lamination (meters)

- f= Frequency of magnetic field (Hz)

👉 To explore more, check our full guide on Eddy current Loss→

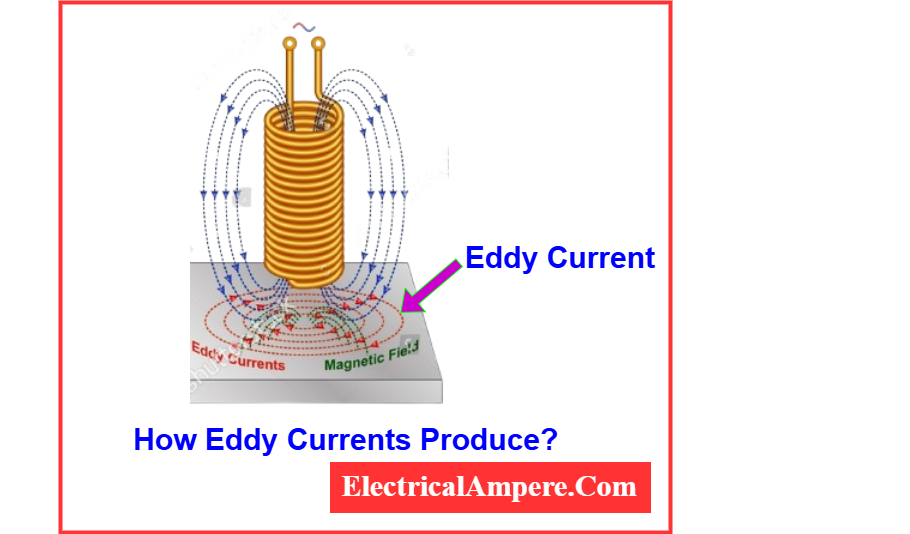

Eddy Current Diagram

A typical eddy current diagram shows a metal plate entering a magnetic field. Inside the metal, small circular arrows appear. These represent loops of electric current—known as eddy currents.

So, what makes them special? In particular, these currents flow perpendicular to the magnetic field lines. As a result, they generate their own magnetic fields. These fields push back against the original magnetic field. That’s why the motion slows down—this is Lenz’s Law in action.

Applications of Eddy Currents

Knowing how eddy current is produced helps us understand its wide range of applications:

- Electromagnetic Braking – In trains and elevators

- Induction Heating – In cooking and metal processing

- Metal Detectors – For security and industrial screening

- Electric Meters – To measure energy use

- Magnetic Levitation – Used in maglev trains

Want a deeper explanation? Read our full post on Applications of Eddy Current

Braking System Using Eddy Currents

Eddy current braking, also known as induction braking, is a method that utilizes electromagnetic forces to slow down or stop moving objects. When a conductor, such as a metal disc, moves through a magnetic field, eddy currents are induced within it. These circulating currents generate an opposing magnetic field, which creates a resistive force that slows down the motion.

In eddy current brake systems, this principle is harnessed to decelerate moving components like coils, rotors, or wheels without physical contact. The braking force is generated by the interaction between the magnetic field and the eddy currents, eliminating the need for traditional friction-based components. This results in smoother and quieter braking, with reduced wear and maintenance.

Due to their efficiency and durability, eddy current brakes are now increasingly used in modern vehicles and high-speed trains, offering a reliable and maintenance-friendly alternative to conventional braking systems.

Eddy Current Testing

Eddy current testing (ECT) is a widely used method in nondestructive testing (NDT). It relies on electromagnetic induction to detect flaws, cracks, or material inconsistencies in conductive materials—without damaging the product. This technique identifies the presence and behavior of eddy currents in metals, which can reveal defects or structural changes.

ECT is especially useful for inspecting surfaces and tubing. You’ll find it commonly applied in critical industries such as aerospace, automotive, power generation, and manufacturing, where safety and precision are paramount.

👉 Explore more: Eddy Current Testing – Principles, Uses & Benefits →

Conclusion

To sum up, eddy currents are produced when a conductor experiences a changing magnetic field. This concept, rooted in Faraday’s and Lenz’s Laws, plays a vital role in modern electrical and mechanical systems. Whether you’re using a maglev train or an induction stove, you’re witnessing the real-world impact of eddy currents.

FAQs – How Eddy Current is Produced

Eddy currents are loops of electric current induced within conductors by a changing magnetic field.

Eddy currents are produced when a conductor is placed in or moved through a changing magnetic field.

Faraday’s Law of Electromagnetic Induction explains how eddy currents are induced.

It is the heat energy lost when eddy currents flow within the conductor. It lowers the efficiency of electrical devices.

Using laminated metal cores and magnetic materials with high resistance helps reduce eddy current losses.

Eddy currents can cause unwanted energy loss in electrical devices by generating heat inside conductors. This reduces efficiency, especially in transformers, motors, and generators. To minimize these losses, designers use laminated cores and materials with high electrical resistance.

Eddy currents themselves are safe and non-harmful. In fact, they are widely used in practical applications such as electromagnetic braking, induction heating (like in cooktops), metal detection, and non-destructive testing to detect material flaws. Proper design ensures they don’t cause overheating or damage.

They are electric currents generated by changing magnetic fields within conductors. Eddy currents can be both beneficial and a source of energy loss, depending on the application. Understanding and managing them is crucial in modern electrical engineering.

Related Article: