Definition: Eddy current loss is the heat generated by the flow of circulating currents( Eddy currents) in a magnetic material.

When a magnetic material is subjected to an alternating magnetic field, it induces an electromotive force (EMF) in the material itself, in accordance with Faraday’s Law of Electromagnetic induction. As the magnetic material is also a conducting material, the EMFs generated circulate current within the body of the material, and this current is known as eddy current. The eddy current is produced when the conductor experiences a changing magnetic field.

These currents, known as eddy currents, do not perform any useful work and instead cause a loss, called I2R loss, in the magnetic material. This loss increases temperature, similar to hysteresis loss.

The losses in a magnetic material are known as iron or core losses and are caused by hysteresis and eddy currents.

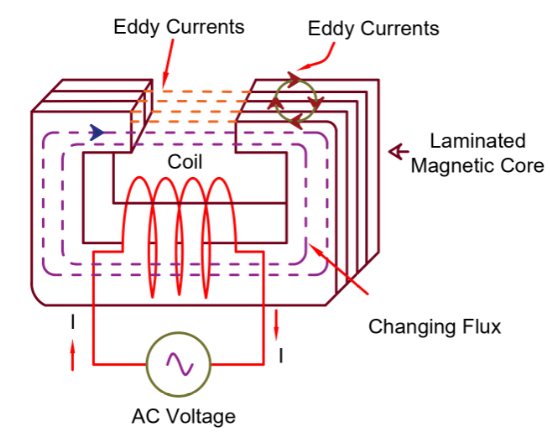

A sectional view of the magnetic core is shown in the figure above. When the changing flux links with the core, it induces emf in the core, which sets up the circulating current called Eddy Current. This current, in return, produces a loss called eddy current loss or (I2R) loss, where I is the current value, and R is the resistance of the eddy current path.

In the above figure, we can see a sectional view of the magnetic core. When the flux changes and links with the core, it induces an electromotive force (emf) in the core. This EMF sets up circulating currents known as Eddy Currents, which produce an Eddy Current Loss or (I2R) Loss. I represent the current value, while R represents the resistance of the eddy current path.

If the core is made of solid iron with a larger cross-sectional area, the current will be high, resulting in higher losses.

Methods of Reducing Eddy Current Loss

Two methods are used to reduce eddy current losses.

By Reducing the magnitude of the eddy current

The strength of an electrical current can be decreased by dividing the solid core into thin sheets referred to as laminations. These sheets are arranged parallel to the magnetic field and are insulated from each other using a thin layer of varnish or oxide film coating.

By Laminating the core

By laminating the core, the area of each section is reduced, which lowers the induced emf. This is because the smaller area through which the current passes increases the resistance of the eddy current path.

Mathematical Expression for Eddy Current Loss

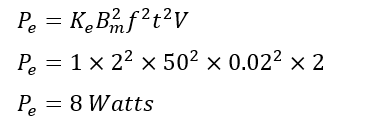

Determining the eddy current loss from resistance and current values is difficult. However, experiments have shown that the eddy current power loss in a magnetic material can be calculated using the following equation:

where,

Ke – co-efficient of eddy current. Its value depends upon the nature of the magnetic material

Bm – maximum value of flux density in wb/m2

t – thickness of lamination in meters

f – frequency of reversal of the magnetic field in Hz

V – volume of magnetic material in m3

Solved Problem

Calculate the eddy current loss for a material with an eddy current coefficient of 1, a thickness of 0.02 m, and a volume of 2 m³. The material is placed in a magnetic field with a maximum flux density of 2 tesla and is supplied by an AC source with a frequency of 50 Hz.

Given Data-

Ke –1

Bm – 2 wb/m2

t – 0.02m

f – 50 Hz

V – 2 m3

Applications of Eddy Currents

Eddy current is a phenomenon that causes heat production, which unfortunately results in energy loss in AC machines such as transformers, generators, and motors. This loss of energy is referred to as Eddy Current Loss. Although this energy loss is not helpful, eddy current can have some applications, such as induction heating.

- Induction heating involves placing an iron shaft as the core of an induction coil. When a high-frequency current is passed through the coil, a large amount of heat is produced at the outermost part of the shaft due to the eddy current. However, the amount of heat reduces towards the center of the shaft. This is because the outermost periphery of the shaft offers a low resistance path for the eddy currents. This process is commonly used in automobiles for surface hardening of heavy shafts.

- In induction-type energy meters, eddy currents provide a braking torque. This helps to slow down the rotation of the meter disc, making it easier to measure the amount of electrical energy consumed. These instruments can accurately and precisely measure electricity by leveraging this phenomenon, making them an essential tool in many applications.

- Permanent magnet-moving coil instruments require damping torque to ensure accurate readings. The eddy current provides damping torque.

- Eddy current instruments are commonly used in the industry to detect cracks or other defects in metal parts.

- Eddy currents are used in trains for braking applications.