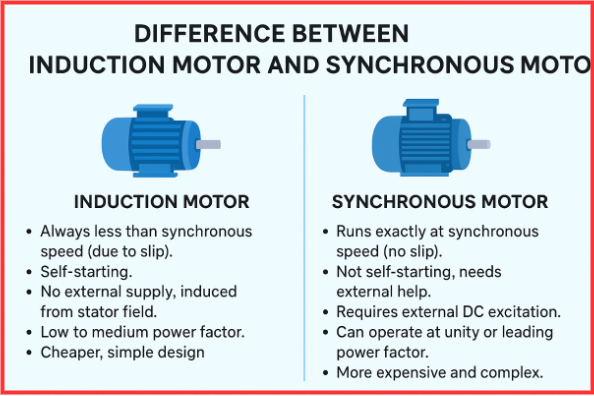

In electrical engineering, two of the most widely used machines are induction motors and synchronous motors. The main difference between induction motor and synchronous motor is that an induction motor always runs at a speed lower than synchronous speed due to slip, while a synchronous motor runs exactly at synchronous speed with no slip.

Understanding this difference is important because both motors are widely used in industries, but their working principles, speed control, and applications differ significantly.

What is an Induction Motor?

An induction motor is a type of AC motor in which the rotor receives power through electromagnetic induction from the stator’s rotating magnetic field, without any direct electrical connection.

Structurally, an induction motor has two main parts: the stator and the rotor. The stator carries a three-phase winding connected to an AC supply, while the rotor is fitted with a short-circuited winding.

When the stator winding is energized, it produces a rotating magnetic field (RMF). This field sweeps across the air gap and cuts through the stationary rotor conductors. Due to the relative motion between the RMF and the rotor, an EMF is induced in the rotor conductors, in accordance with Faraday’s law.

Since the rotor winding is short-circuited, this induced EMF drives a current through the rotor conductors. Now, these current-carrying conductors experience a force when placed in the stator’s magnetic field. The combined effect of these forces generates a torque, which causes the rotor to start rotating.

The rotor follows the direction of the rotating magnetic field but never fully catches up with it—this slight difference in speed, called slip, is what makes induction possible.

Key Features of Induction Motor

- Operating Speed:

Induction motors run at a speed slightly less than the synchronous speed. This difference in speed, known as slip, allows the rotor to induce current from the stator, which generates torque. - Starting Method:

These motors are self-starting and do not need any external excitation or DC supply. The motor starts automatically when connected to the AC supply. - Design & Construction:

Induction motors have a simple and rugged design, making them highly durable. Their construction is cost-effective, which is why they are widely used in various industries. - Types Available:

They are available in both single-phase and three-phase types, catering to a wide range of applications from household appliances to heavy industrial machinery. - Maintenance & Reliability:

Induction motors are low maintenance and reliable. Their robust design ensures long life and stable performance under different load conditions.

Applications of Induction Motor:

- Household appliances (fans, pumps, washing machines).

- Industrial machinery (compressors, conveyors, blowers).

- Agricultural pumps and small mechanical equipment.

What is a Synchronous Motor?

A synchronous motor is an AC motor that runs precisely at synchronous speed, meaning the rotor rotates in step with the rotating magnetic field generated by the stator.

Unlike induction motors, there is no slip under steady load conditions—the rotor speed remains locked with the stator’s field as long as the applied load does not exceed a certain limit. If the shaft load goes beyond this limit, the motor loses synchronism, the rotor comes to rest, and the average torque drops to zero.

The motor is built from two main components: the stator and the rotor. The stator is equipped with a three-phase armature winding connected to a balanced AC supply, which creates a rotating magnetic field. The rotor, typically designed with salient poles, is excited by direct current (DC) to form alternate north and south poles.

For proper operation, the stator and rotor are wound for the same number of poles. This allows the magnetic field of the stator to lock with that of the rotor, ensuring the motor runs in exact synchronism with the supply frequency. As a result, a synchronous motor maintains constant speed regardless of load variations—up to its stability limit.

Key Features of Synchronous Motor

- Operating Speed:

Synchronous motors run at a constant speed, known as synchronous speed, which remains the same regardless of the load on the motor. This makes them ideal for applications requiring precise speed control. - Rotor Excitation:

The rotor requires external DC excitation to produce the magnetic field necessary for motor operation. Without this excitation, the motor cannot run. - Starting Method:

Synchronous motors are not self-starting. They require auxiliary means such as damper windings or an external motor to bring them up to synchronous speed before normal operation. - Efficiency & Power Factor:

These motors are highly efficient and can operate at unity or leading power factor, making them useful for power factor correction in industrial systems. - Construction & Reliability:

Synchronous motors have a robust construction designed for long-term industrial use. They are suitable for applications where speed stability and precise timing are important.

Applications of Synchronous Motor:

- Power factor correction in industries.

- High-precision applications (clocks, record players, robotics).

- Large-scale operations requiring constant speed (rolling mills, compressors).

Difference Between Induction Motor and Synchronous Motor (Tabular Form)

| Feature / Key Point | Induction Motor | Synchronous Motor |

| Type of Machine | Singly-excited – only the stator is supplied with AC; rotor currents are induced. | Doubly-excited – stator connected to AC, rotor field excited by DC. |

| Operating Speed | Always below synchronous speed due to slip. Speed drops with load. | Runs exactly at synchronous speed, independent of load (within limit). |

| Starting | Self-starting with direct starting torque. | Not self-starting – needs damper winding, auxiliary motor, or starter. |

| Rotor Supply / Excitation | No external supply; rotor currents induced from stator field. | Requires external DC excitation to form poles. |

| Power Factor | Always lagging, poor at heavy loads, cannot be controlled. | Can run lagging, unity, or leading. Excitation control improves PF. |

| Efficiency | Moderate due to slip and rotor copper losses. | Higher than induction motors of the same rating (no slip losses). |

| Relative Motion | Needs slip for induction to occur between stator field and rotor. | No slip needed; rotor poles lock with rotating stator field. |

| Cost | Cheaper, simple design, widely used. | More expensive due to DC excitation and complex parts. |

| Construction | Simple (squirrel cage or wound rotor), robust, easy to maintain. | Complex (salient/cylindrical rotor) with excitation system. |

| Starting Torque | Moderate torque, enough for pumps, fans, compressors. | High torque after synchronism, but needs help to start. |

| Speed Range (RPM) | Economical for medium/high speeds (above 600 RPM). | Better for low-speed, high-power jobs (below 300 RPM). |

| Maintenance | Low maintenance, esp. squirrel cage type (no brushes/slip rings). | Higher maintenance – slip rings, brushes, excitation needed. |

| Reliability | Very rugged and reliable, tolerates load swings well. | Less reliable under fluctuating loads; may lose synchronism. |

| Applications | Fans, pumps, compressors, conveyors, household and general drives. | Constant-speed drives, power factor correction, mills, precision tools. |

Quick Summary: Induction vs Synchronous Motor

- Speed: Induction motor runs below synchronous speed, synchronous motor runs exactly at synchronous speed.

- Starting: Induction is self-starting, synchronous needs external help.

- Rotor Supply: Induction motor has induced rotor current, synchronous motor needs DC supply.

- Power Factor: Induction motor has low to medium PF, synchronous can run at unity or leading PF.

- Cost: Induction motors are cheaper, synchronous motors are expensive.

- Applications: Induction for household/industrial loads, synchronous for heavy industries and PF correction.

Conclusion

The difference between induction motor and synchronous motor lies mainly in their speed and excitation method. While induction motors are self-starting, rugged, and run below synchronous speed, synchronous motors maintain exact synchronous speed but require external excitation and starting methods.

Both types of motors are indispensable: induction motors dominate everyday applications due to their simplicity and low cost, while synchronous motors are chosen for constant-speed and power factor correction needs in industries.

Related Articles: