An AC motor is an electrical machine that transforms alternating current into mechanical rotation. AC motors, also known as alternating current motors, are widely used in various applications due to their reliability, efficiency, and simplicity. This article delves into the definition, working principles, key components, and applications of AC motors.

Definition of AC Motor

An AC motor is driven by alternating current (AC). Unlike DC motors powered by direct current, AC motors operate using an AC power source. These motors convert electrical energy into mechanical energy to perform various tasks, from powering household appliances to industrial machinery.

Working Principle of AC Motor

The working principle of an AC motor is based on the interaction between the magnetic field generated by the stator and the induced magnetic field in the rotor. Here’s a step-by-step explanation of how an AC motor works:

- Stator Magnetic Field: When AC power is supplied to the stator windings, it generates a rotating magnetic field.

- Induced EMF in Rotor: This rotating magnetic field induces an electromotive force (EMF) in the rotor windings (for induction motors) or causes the rotor to follow the rotating field (in synchronous motors).

- Rotor Motion: The interaction between the stator’s rotating magnetic field and the induced magnetic field in the rotor creates a torque, causing the rotor to turn.

- Continuous Rotation: As long as the AC power is supplied, the rotor turns, converting electrical energy into mechanical energy.

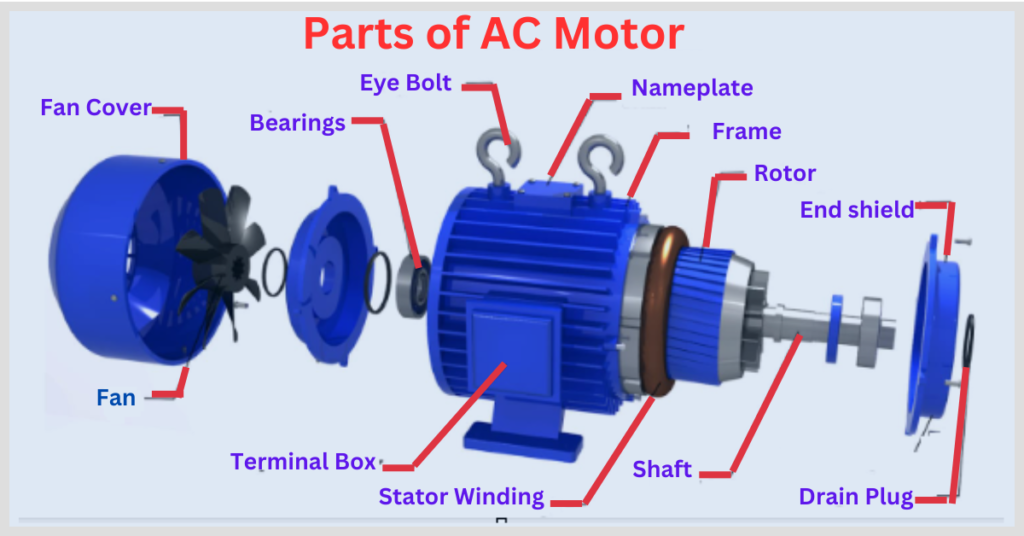

Parts of AC Motor

An AC motor consists of several essential parts, each playing a critical role in its operation:

1. Stator

The stator, the stationary part of the motor, generates the magnetic field. It is made up of laminated steel sheets and has insulated copper or aluminum wire windings.

2. Rotor

The rotor is the rotating part of the motor located inside the stator. Depending on the motor design, it can be either a squirrel cage type or a wound type.

3. Bearings

Bearings provide support to the rotor and enable it to rotate smoothly with minimal friction. They are crucial for the efficient operation and longevity of the motor.

4. Shaft

The shaft is the component that transfers mechanical energy from the motor to the connected load. It is connected to the rotor and extends outside the motor housing.

5. Housing

The housing encloses the motor’s internal components, protecting them from external elements and ensuring safety. It also aids in heat dissipation.

6. Cooling System

AC motors often have a cooling system, such as a fan or cooling fins, to dissipate the heat generated during operation and maintain optimal operating temperatures.

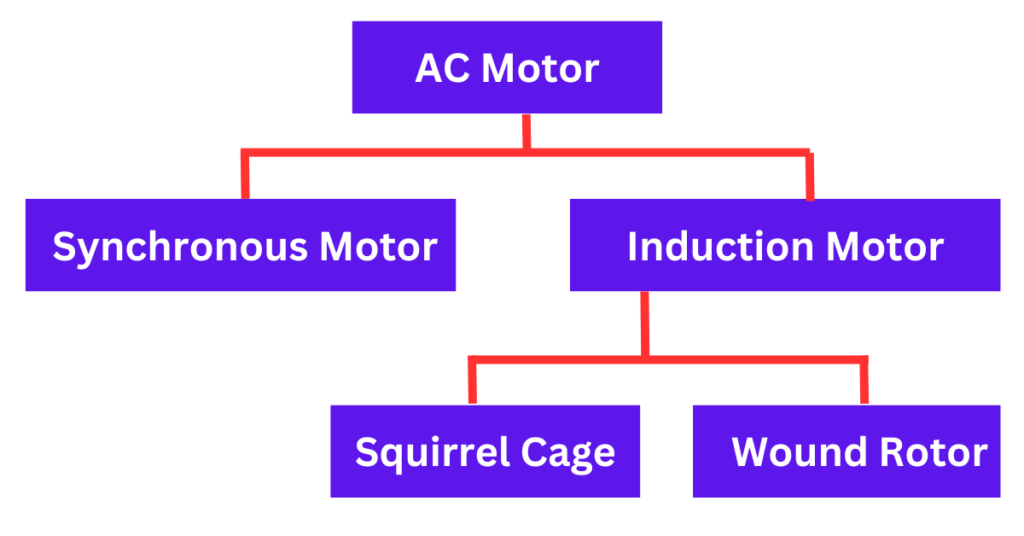

Classification of AC Motor

AC motors are widely used in various applications due to their reliability, efficiency, and versatility. They can be classified based on different criteria, such as the rotor type and operation principle.

Classification Based on Operation Principle

1. Synchronous Motor

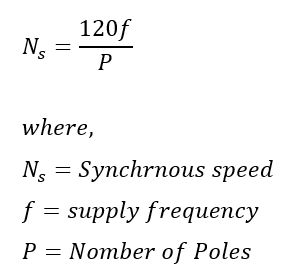

Synchronous motors operate at a constant speed synchronized with the frequency of the AC power supply. The rotor’s rotation matches the speed of the stator’s magnetic field. You can calculate the synchronous speed of the AC motor using the following formula.

These motors are used in applications where precise and constant speed is required, such as clocks, timers, and synchronous conveyors.

Key Characteristics:

- Constant speed operation

- Requires an additional DC supply for the rotor

- High efficiency

Woking Principle of Synchronous Motor

- A rotating magnetic field is generated when AC power is supplied to the stator windings.

- This magnetic field rotates at a synchronous speed, which is determined by the frequency of the AC power supply and the number of poles in the motor.

- The rotor is supplied with direct current (DC) through slip rings, which create a constant magnetic field. This DC supply is fed from an external source or an internal excitation system.

- The interaction between the stator and rotor magnetic fields produces a constant torque, which drives the load connected to the motor shaft.

- As long as the motor is supplied with the appropriate AC power and the rotor excitation is maintained, the synchronous motor runs at a constant speed. Any attempt to vary the rotor speed from synchronous speed results in a loss of synchronization, causing the motor to stop.

2. Induction Motor

The most common type of AC motor is the induction motor. They operate based on electromagnetic induction, where the stator’s rotating magnetic field induces a current in the rotor, causing it to turn. There are two types of induction motors: squirrel cage and wound rotor.

Key Characteristics:

- Simple and rugged construction

- Cost-effective and low-maintenance

- Variable speed with load variations

Woking Principle of Induction Motor

- When AC power is supplied to the stator windings, it generates a rotating magnetic field that rotates at a synchronous speed.

- The stator’s rotating magnetic field cuts across the rotor conductors. According to Faraday’s Law of Electromagnetic Induction, this induces an electromotive force (EMF) in the rotor.

- The induced EMF causes current to flow in the rotor conductors. The rotor current generates its magnetic field, which interacts with the stator’s rotating magnetic field.

- The interaction between the stator’s rotating magnetic field and the rotor’s induced magnetic field produces a torque on the rotor. This torque causes the rotor to start turning in the direction of the rotating magnetic field.

- The rotor never reaches synchronous speed. Instead, it runs at a slightly lower speed. The difference between synchronous speed and the actual rotor speed is called “slip.” Slip is necessary to induce current in the rotor and generate torque.

- As long as the motor is powered, the rotating magnetic field continues to induce current in the rotor. The motor maintains a constant speed slightly less than the synchronous speed, allowing for continuous operation and torque production.

Classification Based on Rotor Type

1. Squirrel Cage Induction Motor

Squirrel cage induction motors have a rotor constructed with bars short-circuited by end rings, resembling a squirrel cage. These motors are known for their simplicity, durability, and low cost.

Key Characteristics:

- Robust and reliable

- Requires minimal maintenance

- Suitable for most industrial applications

2. Wound Rotor Induction Motor

Wound rotor induction motors have a rotor with windings connected to external resistors or controllers through slip rings. This design allows for better control of the motor’s speed and torque.

Key Characteristics:

- Adjustable speed and torque

- Higher starting torque compared to squirrel cage motors

- Used in applications requiring variable speed control

Applications of AC Motor

AC motors are versatile and find applications in various sectors due to their robust performance and efficiency. Some common applications include:

1. Industrial Machinery: AC motors power various industrial equipment, such as conveyor belts, pumps, compressors, and cranes, ensuring smooth and efficient operations.

2. Household Appliances: Many household appliances, including washing machines, refrigerators, air conditioners, and fans, rely on AC motors for their operation.

3. HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems use AC motors to drive fans, blowers, and compressors, providing temperature control and air circulation in buildings.

4. Transportation: AC motors are used in electric vehicles (EVs), trains, and elevators, contributing to efficient and eco-friendly transportation solutions.

5. Power Tools: Various power tools, such as drills, saws, and grinders, use AC motors to deliver the necessary torque and speed for different tasks.

Conclusion

AC motors are integral to modern technology, offering efficient and reliable solutions across various applications. Understanding their definition, working principles, key components, and applications provides valuable insights into their operation and significance in everyday life and industrial processes.

Read Next: