A vacuum circuit breaker is a kind of breaker that utilizes a vacuum as an arc extinction medium. The fixed and moving contact is enclosed within a vacuum interrupter that is permanently sealed. When the contacts separate in a high vacuum, the arc is extinguished. The vacuum circuit breaker is primarily used for medium voltage ranging from 6.6 kV to 33 kV.

The vacuum circuit is superior to other types of circuit breakers due to its high-insulating medium for arc extinction. The pressure inside the vacuum interrupter is around 10-4 torr, which means there are very few molecules present in the interrupter. The vacuum circuit breaker has two main properties that make it an exceptional choice.

- Compared to other insulating media used in circuit breakers, vacuum is a superior dielectric medium. It is better than all other media except air and SF6, employed at high pressure.

- When the contacts of an electrical circuit are separated in a vacuum, an arc is created. This arc is interrupted at the first current zero, resulting in an increase in dielectric strength that is thousands of times greater than other types of breakers.

The aforementioned properties make the breakers more efficient, less bulky, and cheaper, with a longer service life and requiring almost no maintenance.

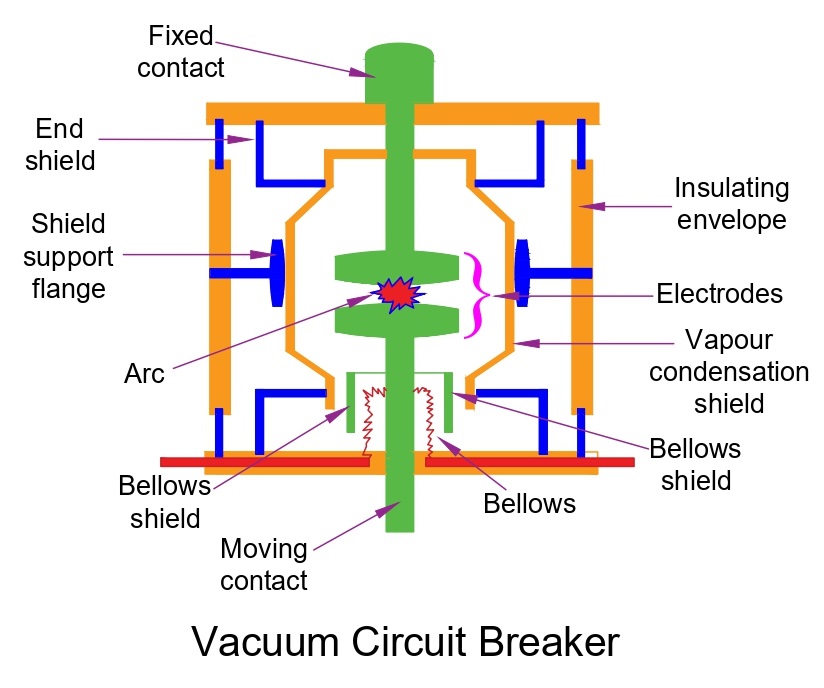

Construction of Vacuum Circuit Breaker

The construction of circuit breakers is divided into three parts: fixed contacts, moving contact, and an arc shield located within the arc interrupting chamber. It is simpler in construction than other circuit breaker types.

The outer casing of a vacuum circuit breaker is typically made of glass. This is because the glass casing allows for easy inspection of the breaker from the outside after it has been operated. If the glass casing becomes milky or cloudy in appearance, it is an indication that the breaker is losing its vacuum.

The contacts of the circuit breaker, both fixed and moving, are positioned inside the arc shield. When the circuit is interrupted, the pressure inside the vacuum interrupter is maintained at around 10-6 torr. The distance that the moving contacts travel varies between 5 to 10 mm, depending on the voltage at which the circuit is operating.

The vacuum circuit breaker uses stainless steel metallic bellows to move the contacts. The design of the metallic bellows plays a crucial role in the lifespan of the vacuum circuit breaker, as it must perform repeated operations satisfactorily.

Working Vacuum Circuit Breaker

When a fault occurs in the system, the contacts of the circuit breaker move apart, creating an arc between them. As the current-carrying contacts are pulled apart, their connecting parts experience a high temperature, which causes ionization. This ionization fills the contact space with a vapor of positive ions that are discharged from the contact material.

The density of vapor is dependent on the current flowing through the circuit. As the current wave decreases, the vapor release rate also falls. Once the current reaches zero, the medium regains its dielectric strength, provided that the vapor density around the contacts has been reduced. As a result, the arc does not restrike again because the metal vapor is quickly removed from the contact zone.

Current Chopping in Vacuum Circuit Breaker

Dependence of current chopping in vacuum circuit breaker on vapor pressure and electron emission properties of contact material. The thermal conductivity influences the current chopping level – lower thermal conductivity results in a lower chopping level.

It is possible to lower the current level at which chopping occurs by choosing a contact material that produces enough metal vapor to allow the current to drop to a very low or zero value. However, this is seldom done because it negatively impacts the dielectric strength.

Vacuum Arc recovery of Vacuum Circuit Breaker

The high vacuum has very high dielectric strength. The arc is extinguished quickly with no current and the dielectric strength is established rapidly. This increase in dielectric strength occurs because the vaporized metal that is localized between the contacts diffuses rapidly due to the absence of gas molecules. After interrupting an arc, the recovery strength is 1 kV/µs in the first few microseconds for an arc current of 100A.

Due to these unique attributes, vacuum circuit breakers can easily handle the severe recovery transients associated with short-line faults.

Property of contact material

The contact material used in the vacuum circuit breaker must possess the following properties.

- The material must have high electrical conductivity to carry normal load currents without overheating.

- For optimal performance, the material used for the contact should have a high density and low resistance.

- The material should have high thermal conductivity to quickly dissipate the heat generated during arcing.

- The material needs to possess a high arc withstand capacity and a low current chopping level.

Advantages of Vacuum Circuit Breaker

Rapid recovery of high dielectric strength occurs on current interruptions that last only half a cycle or less after proper contact separation.

- Vacuum circuit breakers do not require any additional oil or gas and do not need periodic refilling.

- Rapid recovery of high dielectric strength occurs on current interruptions that last only half a cycle or less after proper contact separation.

- The breaker unit is designed to be compact and self-contained and easily installed in any required orientation.

- Due to the aforementioned reasons and the economic advantages they offer, vacuum circuit breakers have gained widespread acceptance.

Disadvantages of Vaccum Circuit Breaker

- The production of vacuum interrupters requires high-tech requirements.

- Additional surge suppressors are required to interrupt low magnetizing currents within a specific range.

- Transit damage or failure causing loss of vacuum causes the entire interrupter useless, as it cannot be repaired on-site.

Applications of Vacuum Circuit Breaker

- Due to their short response time and efficient recovery, vacuum circuit breakers are highly useful as high-speed switching devices in various industrial applications.

- These breakers demonstrate clear superiority over other breakers when the voltage is high, and the current to be interrupted is low.

- Interrupting devices with low fault capacities are less expensive than others.

- Due to low maintenance requirements, these breakers are suitable for systems requiring 11 to 33 kV.