Learn the eddy current definition with formula, diagram, and examples. Understand how eddy currents work, where they’re used, and how to reduce eddy current loss in electrical systems.

Introduction

Have you ever noticed how a speedometer works? Inside, a spinning magnet creates eddy currents in a metal disc. These currents slow the disc down and move the needle, showing your speed. This is just one of the many uses of eddy currents.

Eddy currents play a key role in many everyday devices and technologies. Understanding their behavior helps explain how these devices work and how engineers design systems to control their effects.

Understanding what eddy currents helps connect the theory you learn in class to real-world phenomena around you.

What Is the Eddy Current Definition?

Eddy currents are circular loops of electric current that form inside conductors when they are exposed to a changing magnetic field. This is exactly how eddy current is generated within conductors like copper and aluminum. These currents swirl around, just like water eddies in a river — which is where the name comes from.

Eddy Current in Practical Terms

When a conductor such as copper or aluminum is placed in a varying magnetic field, tiny circular currents begin to flow within it. These induced currents always oppose the change that caused them, following Lenz’s Law. This opposition can produce heat or generate a repelling force.

So, in essence, the eddy current definition refers to the localized electric currents induced within conductors due to a time-varying magnetic field — often resulting in heating or electromagnetic effects. Understanding this helps us see many eddy current examples in daily life where such currents either create useful effects or unwanted losses.

Eddy Current Loss Formula

The power loss due to eddy currents in a conductor can be quantified using this formula: Pe = ke × B² × f² × t²:

Where:

- Pe = Power loss due to eddy currents (in watts)

- ke = Constant that depends on the material and shape of the conductor

- B = Magnetic field strength (in teslas)

- f = Frequency of the changing magnetic field (in hertz)

- t = Thickness of the metal conductor (in meters)

This formula shows that the power loss increases with the square of the magnetic field strength, frequency, and thickness of the metal. Engineers minimize these losses by using laminated cores, high-resistance materials, or thinner sheets in devices like transformers and motors.

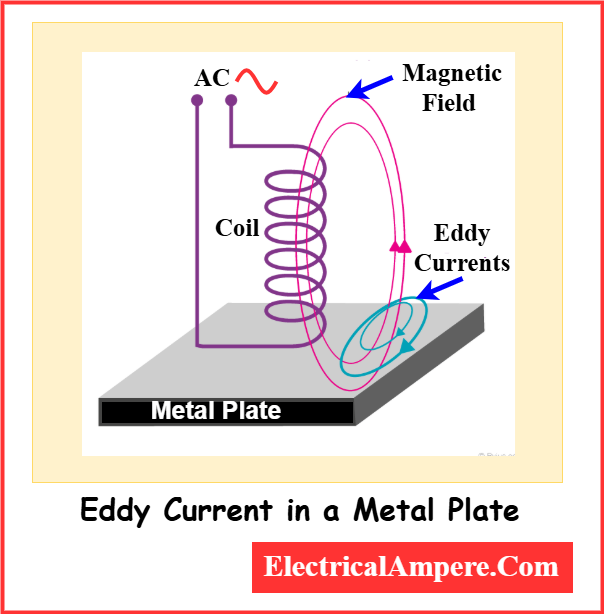

Eddy Current Diagram

In the diagram above, you can see how the magnetic field (B) changes across a metal plate, and as a result, circular currents (eddy currents) are generated within the material. These currents flow in loops, opposing the direction of the changing magnetic field that created them.

This opposition can produce repulsive forces or cause heating—the same principle used in induction cooktops, electric brakes, and energy meters.

Eddy Current Examples

Eddy currents are not just theoretical — they’re used in many devices around us. Here are some real-world examples:

- Induction cookers –Heat pans without an open flame.

- Electric brakes – Used in roller coasters and trains.

- Metal detectors – Find hidden metal objects.

- Speedometers – Show vehicle speed using eddy currents.

- Non-destructive testing (NDT) – Find cracks in metals without cutting them. Learn more about this method in our detailed eddy current testing guide.

These are common eddy current examples in daily life that demonstrate how physics meets practicality in everyday technology.

What Is Eddy Current Loss?

When eddy currents flow, they make heat. This heat is wasted energy. It is called eddy current loss. So, what causes eddy current loss? It’s the internal resistance of the conductor that converts the energy of circulating currents into heat.

To reduce this loss:

- Machines use thin metal layers (laminations).

- High-resistance materials are used.

Understanding what causes eddy current loss helps engineers design more efficient machines, especially in applications like transformers, electric motors, and induction heaters where heat generation must be controlled.

Applications of Eddy Currents

- Braking systems – Used in high-speed trains and gym machines.

- Heat treatment – For welding or melting metals.

- Measuring devices – Like wattmeters and energy meters.

- Safety checks – Detect cracks in airplane parts or pipelines. Explore more uses in our comprehensive applications of eddy current article.

Conclusion

Eddy currents are small loops of current that form inside metals when magnetic fields change. These circulating currents can cause heating or mechanical forces. Their effects are seen in many everyday technologies — from brakes and cookers to electric meters — making eddy currents a common and important phenomenon in daily life.

This topic bridges the gap between magnetism and electricity in real-world applications. By understanding the eddy current definition and the causes of eddy current loss, students and learners can see how textbook concepts translate into practical engineering solutions. This is especially useful for Class 12 physics students, helping them connect theory with hands-on understanding of machines and devices.

FAQs – Eddy Current

Eddy currents are circular currents formed in a metal due to a changing magnetic field. They follow Lenz’s law and oppose the cause that makes them.

They are used in brakes, induction cooking, metal detectors, and electric meters.

It is the loss of energy as heat due to eddy currents. It happens in electrical machines like motors and transformers.

It is the voltage made by a source or by changing magnetic fields. It causes current to flow.

They look like small circles or loops inside a metal. These loops are invisible but can be visualized using diagrams.

It is called an eddy current.

A speedometer is a device that shows how fast a vehicle moves. It uses a spinning magnet to make eddy currents in a disc, which moves the needle.

Eddy currents are widely used in non-destructive testing (NDT) to detect surface and sub-surface flaws in conductive materials. This process is called eddy current testing, and it helps inspect metal parts without damaging them.

Related Articles: