Learn everything about VVVF drive (Variable Voltage Variable Frequency), including its working principle, block diagram, VVVF vs VFD comparison, formula, and key applications in motor control. Discover how VVVF improves efficiency and precision in industrial and transport systems.

What is VVVF Drive?

VVVF Drive stands for Variable Voltage Variable Frequency Drive. It is an advanced type of motor control system used to regulate the speed and torque of AC motors by varying both the voltage (V) and frequency (f) of the power supply. This control technique helps in achieving smooth acceleration, deceleration, energy efficiency, and reduced mechanical stress in electric motors.

VVVF Drive (Variable Voltage Variable Frequency Drive) is also commonly known as a VFD (Variable Frequency Drive). Both terms refer to a system that controls the speed and torque of an electric motor by varying the voltage and frequency of the power supplied to it.

VVVF drives are widely used in elevators, escalators, trains, industrial motors, and HVAC systems.

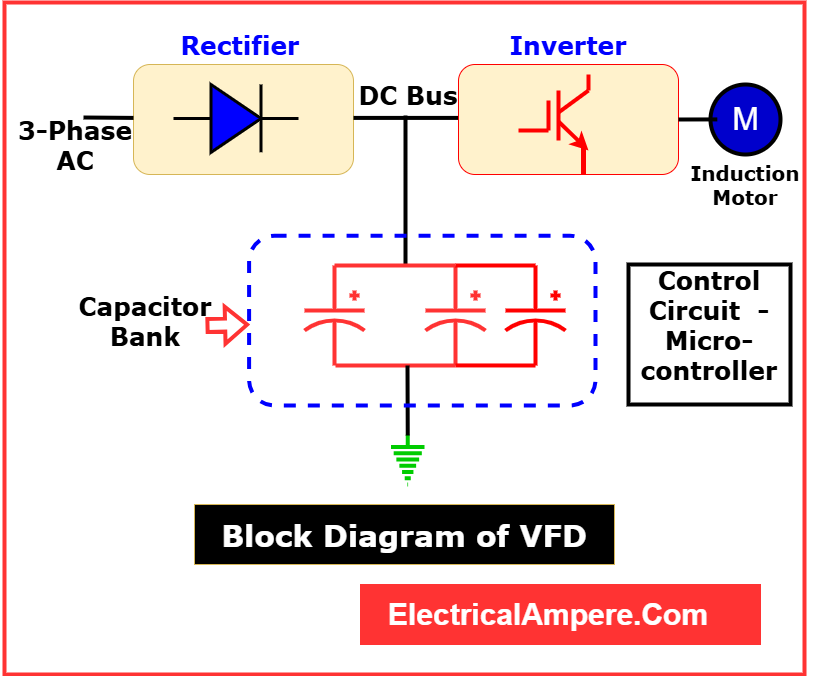

VVVF Drive Block Diagram

A typical VVVF drive block diagram consists of the following major components:

- Rectifier Unit: Converts incoming AC supply to DC.

- DC Link (Filter): Smoothens the DC signal using capacitors and inductors.

- Inverter Unit: Converts the DC back to variable voltage and frequency AC using power electronic switches like IGBTs or MOSFETs.

- Control Circuit: Microcontroller or DSP-based system that determines the desired voltage and frequency output based on input commands.

VVVF Drive Working Principle

The working principle of a VVVF (Variable Voltage Variable Frequency) drive is centered on controlling both the voltage and frequency of the power supplied to an AC motor to regulate its speed and torque. The process occurs in three main stages:. The working principle of a VVVF drive involves three stages

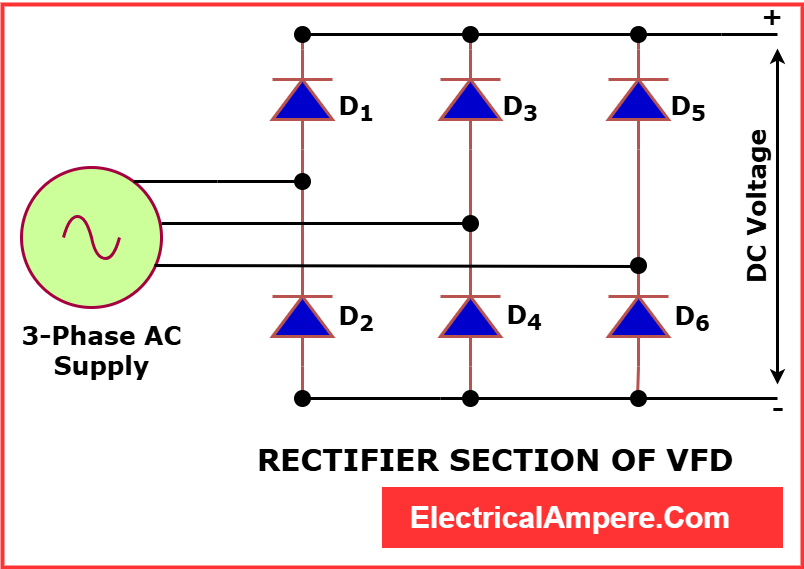

1. AC to DC Conversion (Rectifier Stage):

The incoming AC supply (typically at fixed frequency, e.g., 50 Hz or 60 Hz) is first passed through a rectifier. This rectifier converts the alternating current (AC) into direct current (DC). Depending on the design, either a diode rectifier or a controlled rectifier (thyristor-based) is used. The output at this stage is a pulsating DC.

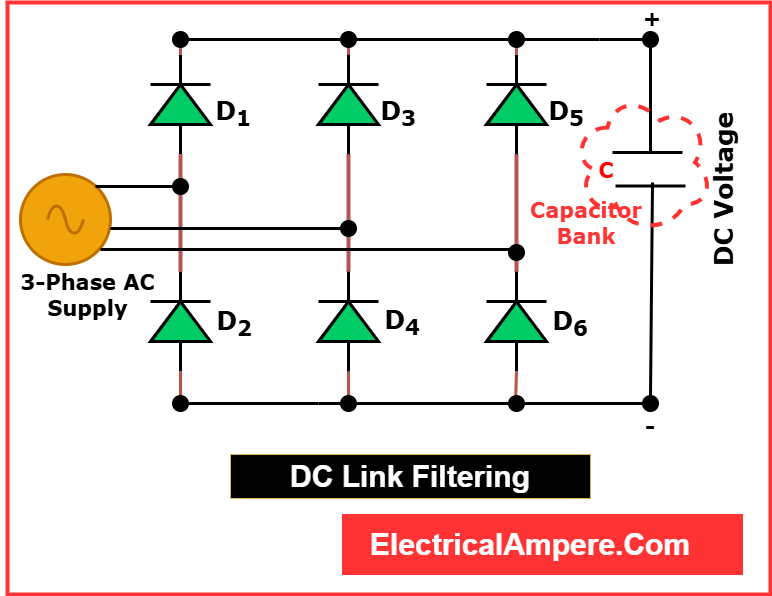

2. DC Link Filtering (Intermediate Stage):

The pulsating DC output from the rectifier is then smoothed using DC link components, which typically include capacitors and inductors. These components filter out ripples and provide a stable and constant DC voltage, which acts as a bridge between the rectifier and the inverter.

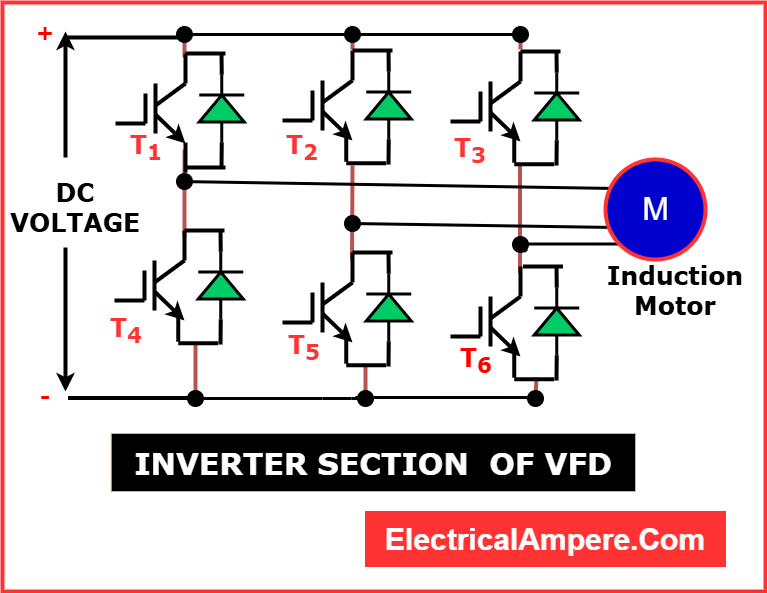

3. DC to Variable AC Conversion (Inverter Stage):

The filtered DC voltage is then fed into an inverter circuit. The inverter uses power electronic switches like IGBTs (Insulated Gate Bipolar Transistors) or MOSFETs, controlled using Pulse Width Modulation (PWM) techniques. PWM allows the inverter to create a synthesized AC waveform whose voltage and frequency can be varied as required.

By controlling the V/f ratio, the drive maintains constant magnetic flux in the motor, ensuring optimal performance and torque control.

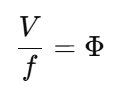

VVVF Drive Formula

The VVVF formula relates voltage and frequency to maintain magnetic flux:

This equation ensures that as frequency increases or decreases, voltage changes proportionally, maintaining efficient motor operation without saturation or torque loss.

VVVF Drive Advantages: Key Benefits

1. Smooth Motor Start-Up

VVVF drives can start motors at zero voltage and frequency. This gentle start helps prevent sudden electrical or thermal stress on motor windings, extending the motor’s service life.

2. Reduced Power Line Disturbance

These drives help eliminate voltage sags caused by direct motor starts, thus protecting sensitive equipment like computers, sensors, and switches from power fluctuations.

3. Lower Start-Up Power Demand

Starting motors directly across the line demands high power, often resulting in utility surcharges. VVVF drives reduce start-up power, helping avoid peak-hour penalties.

4. Controlled Speed and Acceleration

VVVF drives offer precise speed and acceleration control. This is essential in delicate processes—such as bottling fragile products—where smooth operation is crucial. They also allow remote speed adjustments through controllers, enhancing automation.

5. Torque Limiting

VVVF drives can limit and fine-tune torque output, preventing motors from exceeding safe levels. This protects machinery, processes, and final products from damage.

6. Energy and Cost Efficiency

By adjusting motor speed to match demand, VVVF drives lower energy use compared to motors running constantly at full speed. They also eliminate the need for mechanical throttling components, cutting maintenance and operational costs.

VVVF vs VFD

| Feature | VVVF Drive | VFD (Variable Frequency Drive) |

|---|---|---|

| Full Form | Variable Voltage Variable Frequency | Variable Frequency Drive |

| Voltage Control | Yes | Sometimes (not all VFDs control voltage) |

| Application Focus | Precise speed/torque control | General speed control |

| Complexity | More advanced | Less complex |

| Used In | Elevators, Railways, HVAC | Pumps, Fans, Conveyors |

While both are used for motor speed control, VVVF drives provide both voltage and frequency variation, making them more suitable for applications requiring refined control.

Conclusion

A VVVF drive is an essential component in modern motor control systems. Its ability to vary both voltage and frequency enables efficient speed regulation, energy savings, and reduced wear and tear. Whether for industrial motors, electric trains, or building elevators, VVVF drives ensure optimized and intelligent motor performance.

FAQs on VVVF Drive

1. What is the Meaning of VVVF?

VVVF means Variable Voltage Variable Frequency. It refers to a drive system that can change both the amplitude (voltage) and frequency of the AC signal supplied to a motor. This enables precise control over motor behavior, essential in automation, energy-saving systems, and transportation.

2. What is the purpose of a VVVF drive?

A VVVF drive is used to control the speed, torque, and direction of AC motors by varying the voltage and frequency. This helps improve energy efficiency, reduce mechanical stress, and provide smoother operation.

3. How does a VVVF drive differ from a standard VFD?

While both control motor speed, a VVVF drive controls both voltage and frequency, whereas some basic VFDs might only vary frequency. This makes VVVF drives more suitable for precise applications like elevators or electric trains.

4. Where is VVVF drive used?

VVVF drives are commonly used in:

- Elevators and escalators

- Electric trains and metros

- HVAC systems

- Industrial automation and machinery

5. Is VVVF drive same as inverter?

A VVVF drive includes an inverter, but it’s more than just an inverter. It also includes rectifiers, DC links, and control circuits for full motor regulation.

6. What is the main advantage of a VVVF drive?

The main advantage is smooth and energy-efficient control of motor operations, which extends equipment life and improves performance.

7. What kind of motors can use VVVF drive?

VVVF drives are mostly used with AC induction motors and synchronous motors, including those in elevators, trains, and heavy-duty machinery.

8. What is the full form of VVVF?

The full form of VVVF is Variable Voltage Variable Frequency. It refers to a drive system that controls both the voltage and frequency of the electrical power supplied to an AC motor, enabling precise speed and torque control.

9. What is the difference between VSD and VVVF?

VSD (Variable Speed Drive) is a general term for devices that control motor speed by varying input power. VVVF (Variable Voltage Variable Frequency) is a specific type of VSD used with AC motors, where both voltage and frequency are adjusted to control speed. While all VVVF drives are VSDs, not all VSDs are VVVF—some control DC motors using different principles. VVVF is ideal for precise control in AC applications like HVAC and conveyors, offering smooth acceleration and energy efficiency. In summary, VSD is a broad category, and VVVF is a specific method under it.

Read Next: