Learn about the V/f ratio in induction motors, its importance in speed control, how it maintains constant flux, and its role in improving motor performance and efficiency. Ideal for engineers and students.

What is V/f Ratio?

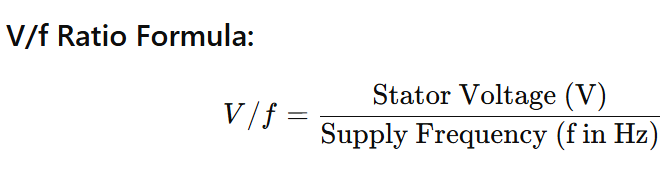

The V/f ratio, also known as Volts per Hertz ratio, is the ratio of the applied stator voltage (V) to the frequency (f) of the supply in an induction motor. It’s a key concept in motor speed control and efficiency, especially when using Variable Frequency Drives (VFDs).

V/f Ratio Formula:

Maintaining a constant V/f ratio ensures that the magnetic flux in the motor remains constant, which is critical for stable torque production and motor health.

How Constant V/f Ratio Maintains the Constant Flux in the Motor?

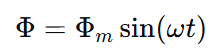

The magnetic flux (Φ) in an induction motor is a critical factor for its performance, particularly for torque production. Let’s understand how the flux is maintained constant when the V/f (voltage to frequency) ratio is kept constant in V/f control of induction motors.

When an AC voltage is applied to the stator winding, a time-varying magnetic flux is produced:

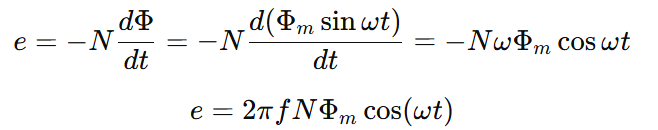

According to Faraday’s Law of Electromagnetic Induction, the self-induced EMF in the stator winding is:

Where:

- e = instantaneous induced EMF

- N = number of turns in the winding

- f = frequency of supply

- Φm = maximum flux

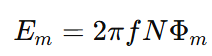

From this, the peak value of the EMF is:

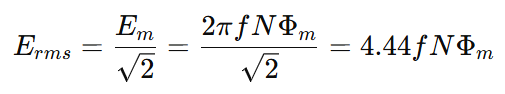

Taking the RMS value of EMF:

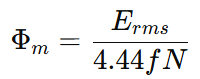

Now rearranging the equation for flux (Φ):

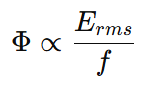

This shows:

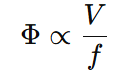

Since the applied voltage V ≈ induced EMF E in the stator (neglecting impedance drops), we get:

From the above derivation:

Φ = V/f

This implies that if the ratio of the applied voltage (V) to frequency (f) is kept constant, the magnetic flux (Φ) in the motor remains constant.

Why is the V/f Ratio Important?

In an induction motor, torque is directly related to magnetic flux. Any change in voltage or frequency affects the flux. Here’s why the V/f ratio matters:

- Prevents Core Saturation: If voltage is too high for a given frequency, the motor core can saturate.

- Avoids Weak Torque: If voltage is too low for a high frequency, the flux and torque drop.

- Ensures Efficient Speed Control: Especially important in fan, pump, and conveyor systems.

- Maintains Motor Health: Helps avoid overheating and insulation damage.

How Does V/f Control Work?

V/f control is a type of scalar control used in VFDs. It works by adjusting both the voltage and frequency supplied to the motor while keeping their ratio constant. This method is commonly used in VVVF (Variable Voltage Variable Frequency) drives, which efficiently control the speed of AC induction motors across various applications.

Example:

To maintain a 220 V/50 Hz = 4.4 V/Hz ratio, if frequency is reduced to 25 Hz, voltage should be reduced to:

This keeps the flux constant and ensures smooth motor operation.

V/f Control Table (for a 440 volts, 50 Hz, 4-pole Motor)

| Frequency (Hz) | Voltage (V) | V/f Ratio (V/Hz) | Synchronous Speed (RPM)=120f/P |

|---|---|---|---|

| 10 | 88 | 8.8 | 300 |

| 20 | 176 | 8.8 | 600 |

| 30 | 264 | 8.8 | 900 |

| 40 | 352 | 8.8 | 1200 |

| 50 | 440 | 8.8 | 1500 |

Operating Zones in V/f Control

1. Constant Torque Zone (up to base frequency):

Voltage and frequency increase proportionally. Motor delivers constant torque. In this region, both voltage and frequency increase proportionally, maintaining a constant V/f ratio. This keeps the magnetic flux constant, allowing the motor to deliver constant torque across the speed range up to the base frequency.

Example: Consider a 440V, 50Hz induction motor (V/f = 8.8 V/Hz):

| Frequency (Hz) | Voltage (V) | V/f Ratio (V/Hz) | Zone | Torque Behavior |

|---|---|---|---|---|

| 10 | 88 | 8.8 | Constant Torque | Full torque available |

| 20 | 176 | 8.8 | Constant Torque | Full torque available |

| 30 | 264 | 8.8 | Constant Torque | Full torque available |

| 40 | 352 | 8.8 | Constant Torque | Full torque available |

| 50 | 440 | 8.8 | Constant Torque | Full torque available |

As long as the V/f ratio is constant, the flux in the motor remains constant, ensuring full torque delivery. This range is ideal for conveyors, elevators, and pumps where constant torque is required at different speeds.

2. Field Weakening Zone (above base frequency):

Frequency increases but voltage stays constant (due to limits). Motor torque drops.

Example: For a 440V, 50Hz induction motor, the V/f ratio is 8.8 V/Hz up to 50 Hz. When we increase frequency beyond 50 Hz:

| Frequency (Hz) | Voltage (V) | V/f Ratio (V/Hz) | Zone | Torque Behavior |

|---|---|---|---|---|

| 50 | 440 | 8.8 | Base Zone | Full rated torque |

| 60 | 440 | 7.33 | Field Weakening | Torque reduces |

| 70 | 440 | 6.29 | Field Weakening | Further torque drop |

| 80 | 440 | 5.5 | Field Weakening | Low torque available |

In the field weakening region, as frequency increases beyond 50 Hz but voltage stays at 440V, the magnetic flux decreases. Since motor torque is proportional to flux, the available torque drops. This zone is suitable for constant power applications (e.g., fans, blowers at high speed), but not ideal for high-load torque.

3. Low Frequency Zone (Below ~5–10 Hz):

Careful voltage boosting is needed to overcome stator resistance and maintain torque. At very low frequencies, the stator resistance becomes significant relative to the motor’s impedance. To maintain the required air-gap flux and deliver sufficient torque, the controller must boost the voltage slightly above the linear V/f ratio.

Example: For a 440V, 50Hz motor (V/f = 8.8 V/Hz), ideally at 5 Hz, the voltage should be:

- 5 Hz × 8.8 V/Hz = 44 V

However, due to stator resistance, a voltage boost is applied:

| Frequency (Hz) | Linear Voltage (V) | Boosted Voltage (V) | Zone | Torque Behavior |

|---|---|---|---|---|

| 2 | 17.6 | 25–30 | Low Frequency | Torque maintained |

| 5 | 44 | 55–60 | Low Frequency | Torque maintained |

| 8 | 70.4 | 75–80 | Low Frequency | Torque maintained |

Without boosting, the voltage drop across the stator resistance at low speed would reduce the air-gap flux, causing torque to fall sharply. The voltage boost compensates for this drop, allowing the motor to start smoothly with sufficient torque, especially under load.

Relationship Between Speed and Frequency

The synchronous speed of a 3-phase induction motor is given by:

Where:

- Ns = synchronous speed in RPM

- f= supply frequency

- P = number of poles

Thus, changing the frequency directly changes the speed of the motor.

Applications of V/f Control in Induction Motors

- HVAC systems

- Industrial drives

- Pumps and blowers

- Elevators and escalators

- Conveyor belts

- Agricultural water pumps

Benefits of V/f Control

The followings are the advantages of VVVF control.

| Feature | Benefit |

|---|---|

| Smooth Speed Variation | Allows precise motor speed control |

| Energy Efficiency | Saves energy in low-load applications |

| Simple Implementation | Easy to set up and maintain |

| Affordable | Cost-effective motor control method |

Comparison: V/f Control vs Vector Control

| Parameter | V/f Control ( VVVF Control) | Vector Control |

|---|---|---|

| Complexity | Low | High |

| Cost | Low | Moderate to High |

| Accuracy | Moderate | High |

| Torque at Low Speed | Limited | Better |

| Applications | General-purpose loads | High-performance systems |

Conclusion

The V/f ratio in induction motor control is essential for smooth, efficient, and reliable motor performance. Whether it’s for small appliances or industrial systems, understanding and maintaining a constant V/f ratio ensures optimal torque production, energy savings, and prolonged equipment life. VVVF drive for V/f control has become one of the most widely used and trusted methods for motor speed control today.

FAQs on V/f Ratio in Induction Motor

1. What is the V/f ratio formula?

The V/f ratio formula is:

V/f = Applied Voltage / Supply Frequency

Maintaining a constant V/f ratio ensures constant magnetic flux in the motor, which is essential for efficient torque production.

2. Why is the V/f ratio kept constant?

The V/f ratio is kept constant to maintain constant magnetic flux in the motor. This ensures that the motor produces consistent torque without saturating the core or weakening the flux, which could otherwise lead to inefficiencies or overheating.

3. What is the V/Hz ratio?

The V/Hz ratio, also known as the V/f ratio, refers to the ratio of voltage to frequency in volts per hertz (V/Hz). It’s crucial in AC motor drives to maintain proper magnetic flux and torque. For example, a 440V motor at 50Hz has a V/Hz ratio of 8.8 V/Hz.

Read Next: