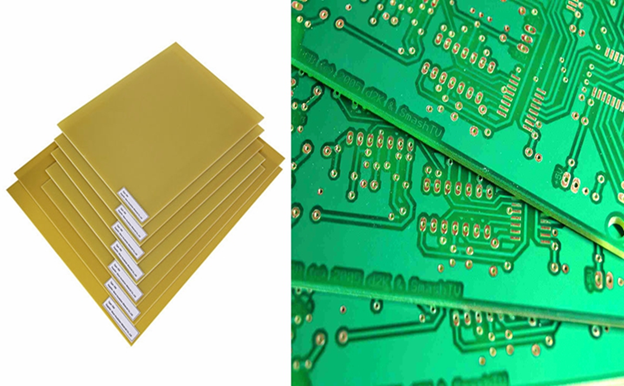

New design requirements that are driven by various market segments have influenced the way printed circuit boards or PCBs are designed and manufactured. The development of PCB solutions is a highly technical effort to fill the need for lightweight, small, cheap, but high-performance electronic systems. Circuit boards have significantly progressed to densely populated boards with complex connections.One of the conventional and mature technologies used as a PCB material is the FR4 PCB substrate.

The primary intent of this article is to understand the basics of PCB board material FR4 and why it is the most commonly used circuit board material.

What is an FR4 PCB Substrate?

An FR4 is a composite material which is made of fibreglass and epoxy resin, commonly used due to its dielectric properties, thermal resistance and good mechanical strength that is ideal for rigid boards. It is a flame retardant type 4 woven fibreglass epoxy resin system, thus the name FR4 or FR4 PCB substrate. . According to history, the first FR4 was developed in the 1960s and used for infrared scans.

The selection of circuit board material FR4 laminate is dictated by several factors such as its electrical, mechanical and thermal properties. These aspects need to be carefully assessed to ensure that the performance of the final PCB is well-aligned with the end requirements. Below are some of the major properties that need to be considered:

- Dielectric Constant: Dielectric constant, abbreviated as Dk, is a measure by which laminates can store electrical energy. It is an important property in keeping signal integrity and impedance control in a PCB. A lower Dk implies better transmission of signals through the PCB substrate. Circuit board material FR4 has a relatively lower DK, which makes it an ideal material for most PCBs.

- Dissipation Factor: Dissipation factor or Df is also referred to as loss tangent, which indicates the degree of loss in energy when subjected to the electric field. A lower Df means that the laminate has less energy loss, which is preferred behaviour of materials to maintain signal integrity. High dissipation factors, on the other hand, can cause more heat to be generated, which can influence the performance of the components and the overall device system. PCB board material FR4 has a lower Df, so it has an excellent performance in common signal transmission.

- Volume Resistivity: A PCB laminate’s ability to resist electrical current through its volume is known as volume resistivity. The thickness of the substrate and surface resistivity are the related parameters to volume resistivity. Higher volume resistivity signifies better insulation capability, which is good for substrates in ensuring electrical performance.FR-4 material has superior performance in resisting electrical current, so it becomes a commonly used material in the PCB manufacturing industry.

- Tensile Strength: PCB laminates are also categorised based on their tensile strength, which is a material’s ability to withstand stress when pulled. This is directly related to the PCB’s resistance to deformation when undergoing mechanical stresses during fabrication, assembly and end applications. FR4 material specification has clear instructions for the production of this material. So this material is widely used in common PCB manufacturing.

- Glass Transition Temperature: The glass transition temperature is the temperature at which the material changes from a rigid to a rubbery phase. This is particularly crucial as it determines how the materials interact at varying temperatures. A higher Tg should be considered for devices that will be used for high-temperature operating ranges.

- Coefficient of Thermal Expansion: Different materials expand differently when exposed to different temperatures. These differences can cause stress due to opposing thermal expansion. The CTE of PCB laminates should be understood to be able to simulate the effect of temperatures on the PCB. The CTE of FR4 PCB material is not as good as that of high-tech materials, but it can meet the needs of most daily applications.

What are the Different Types of FR4 PCB Substrate?

The basic understanding of FR4 circuit board material has now evolved as the quest for better materials with higher requirements has heightened over the past years. The tightened requirements for base materials have pushed fabricators, manufacturers and assemblers to find FR4 substrates that conform to the range of FR4 material specifications. Below are the different types of FR4 PCB substrates:

- Standard FR4. A standard FR4 PCB is a popular type of FR4 substrate made of interwoven fibreglass with epoxy resin, having a glass transition temperature up to 180 degrees Celsius. It has good tensile strength, high dielectric strength and good chemical resistance.

- High TG FR4. A high Tg FR4 substrate has higher glass transition temperature values than standard PCB material FR4 laminates. It has a lesser tendency to expand or shrink with changing temperatures due to its good thermal stability. This type of PCB allows more design flexibility in terms of width and pad sizes due to its dimensional stability.

- High Frequency FR4. Applications like antenna systems and microwave circuits require PCB that can withstand high frequencies. High-frequency FR4 substrates consist of additives to enhance their ability to maintain dielectric properties at elevated frequencies.

- High CTI FR4. Another special type of PCB material FR4 is the high CTI FR4. CTI stands for Comparative Tracking Index, which is a measure of FR4 substrate to resist ‘electrical tracking’, a phenomenon wherein electrical paths are produced on insulating material when it comes in contact with dirt and contaminants. Higher CTI values for FR4 substrates mean that electrical tracking is avoided, lessening the risks of electrical shorts and failures.

What are the Advantages of Using FR4 as a PCB Substrate?

The popularity of FR4 PCB substrate as the main substrate type for many applications is attributed to its several benefits, which are itemised in the following:

- Cost-Effectiveness: Compared with other PCB substrate types such as ceramic and metallic types, FR4 substrate is more affordable. This is because the raw materials used for FR4 are readily available. The processing methods are also relatively easier as FR4 PCB material is easy to drill, cut and laminate.

- Thermal Stability: The good thermal stability of circuit board FR4 material is linked to its favourable properties such as high glass transition temperature and low thermal expansion. Its structural integrity does not easily change even at high temperatures. This advantage is important to have a stable base for electrical components, especially with decreasing sizes of pads and components.

- Flame Retardance: Flame retardant property is a distinguishing feature for FR4 circuit board material substrates. It is extremely important, especially for electronic applications since heating of PCB components is unavoidable when in operation. International standards have outlined rules and policies for safety purposes.

Conclusion

The FR4 substrate PCB material has been widely used in manufacturing. They have many properties, making them an ideal material for the industry and consumer electronics products. As new and high-tech electronics are emerging in the market, this material will be used more often than before. Go get the best quality FR4 PCB you can find a FR4 PCB manufacturer for your business and products.