Definition: The energy wasted in the form of heat due to hysteresis in magnetic materials is called Hysteresis Loss. The magnetizing force works against the internal friction of the magnet’s molecules and produces heat.

What is Hysteresis Loss?

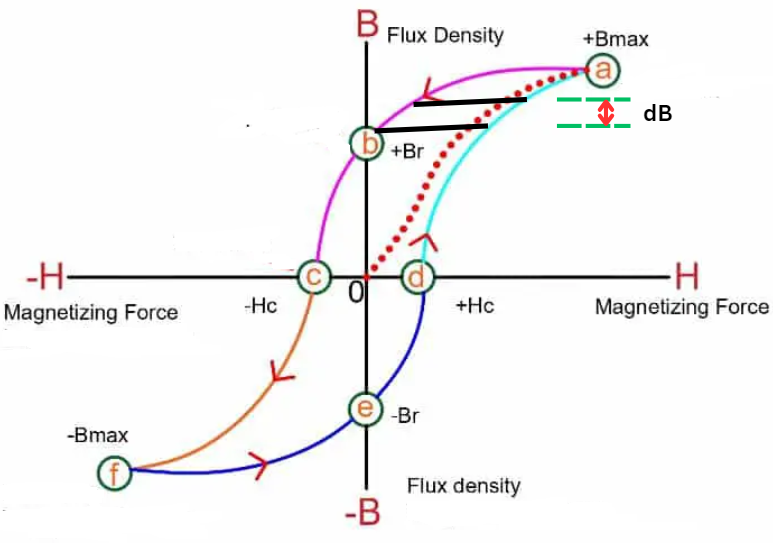

When a magnetization force is applied to a magnetic material, the molecules in the material align in a particular direction. However, when this magnetizing force(H) is reversed in the opposite direction, the internal friction of the molecular magnets resists the reversal of magnetism(B). Therefore, the magnetic field(B) lags the magnetizing force(H), and this phenomenon of a magnetic field lagging with a magnetizing force is called hysteresis. If you observe the B-H curve of a magnetic material, you will find that the magnetic field B always lags the magnetizing force(H).

Image source: electricalvolt.com

In order to overcome the internal resistance within a magnetic material, a portion of the magnetizing force is employed. However, this process generates heat due to work done by the magnetizing force, which results in energy loss in the form of heat. This loss of energy is known as hysteresis loss, and it is directly proportional to the area of the B-H curve.

Let’s take electrical machines as an example to understand the concept. The hysteresis loss mainly occurs in the magnetic parts of the electrical machines, where there is a reversal of magnetism.

The increase in temperature of a machine results in energy loss, mainly in the form of heat, which is an undesirable process. Therefore, a suitable magnetic material with minimal losses and a narrow hysteresis loop is used for electrical machinery parts.

How can we Reduce Hysteresis Losses?

To reduce hysteresis losses, it is recommended to use materials that have a smaller area of the hysteresis loop. For instance, high-grade or silica steel is a good choice for designing the transformer’s core because it has an extremely small area of the hysteresis loop.

To reduce losses in transformers, it is possible to increase the number of laminations and reduce the gaps between the plates. To decrease hysteresis loss, a soft core with less hysteresis, such as silicon steel(CRGO), can be chosen.

The grains in CRGO (Cold Rolled Grain Oriented) steel are intentionally made larger, about 10 times the size of grains in regular steel. These grains are grown and aligned almost parallel to the direction of the rolling of the steel. Therefore, hysteresis loss of CRGO core is minimal.

The density of flux, laminated core, and frequency are the main factors that influence these losses.

Factors Affecting Hysteresis Loss

The following factors affect hysteresis loss.

- The hysteresis loop is narrow so that the material can be easily magnetized.

- If the material is difficult to magnetize, the resulting hysteresis loop will be larger.

- At various ‘B’ values, different materials can saturate, affecting loop height.

- The physical properties of the material largely determine the loop.

- The size and shape of the loop depend primarily on the specimen’s initial position.

- The hysteresis loss increases as the frequency and magnetic flux density increase.

- The loss increases with the increase in the volume of magnetic material.

Hysteresis Loss Formula

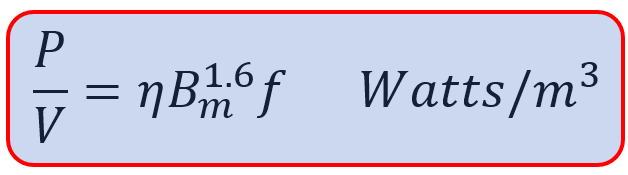

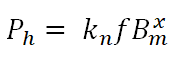

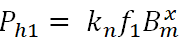

The formula for hysteresis loss is given below.

Where,

Ph – Hysteresis loss in watts

Ƞ – Steinmetz’s constant in J/m3, its value depends upon the nature of the magnetic material.

Bm – Maximum value of the flux density in the magnetic material in wb/m2

f- Number of cycles of magnetization made per second

V- Volume of the magnetic material (part in which magnetic reversal occurs) in m3

The hysteresis loss per unit volume is.

If you know the shape of the B-H curve, you can calculate this loss by calculating its area.

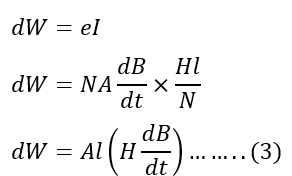

We will mathematically prove that the hysteresis loss per unit volume is equal to the area of the hysteresis loop. Let’s take a BH curve.

We consider a small thickness dB strip on the hysteresis loop. The flow of the current (I ) in a coil produces a magnetic field in the magnetic material. The magnetic field in the specific area is called flux. Thus, magnetic flux is ;

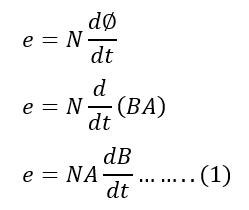

When the current passing through a coil changes, it induces an electromotive force (e.m.f.) due to the change in flux.

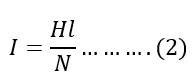

Magnetic field strength (H) is;

Therefore,

The power expended in maintaining the current ‘I’ against induced EMF ‘e’ is known as the power or rate of energy expenditure.

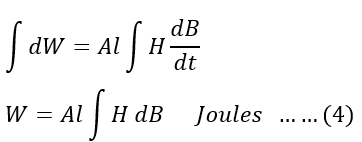

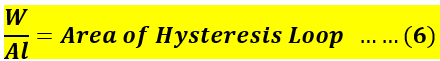

Equation 3 can be integrated on both sides to obtain the total work done during a complete cycle of magnetization.

Where ʃ HdB is the area of the hysteresis loop.

Work done /unit volume (W/m3),

A smaller area of the hysteresis loop indicates that there is less hysteresis loss. Soft magnetic material has a smaller BH loop area and lower loss. In contrast, the hard magnetic material has more loss due to the greater BH curve area.

Solved Example

The hysteresis loss of a 1-phase transformer working on 200 V, 50 Hz is Ph. What would be the percentage decrease in this loss when operated on a 160 V, 40 Hz?

Solution:

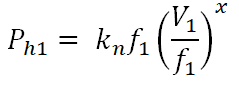

Hysteresis loss formula is.

Loss in the core at f1 frequency,

Since,

Therefore,

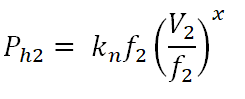

and,

% decrease in loss,

Hence, the % decrease in hysteresis loss would be 20 %.