Tube light is one of the most widely used sources of artificial lighting in homes, offices, schools, and industries. It provides bright, uniform illumination with relatively low power consumption compared to traditional incandescent bulbs. To understand how it works, let’s explore the tube light meaning, its parts, and the working principle of tube light in detail.

Tube Light Meaning

Tube light means a type of fluorescent lamp that produces visible light by exciting mercury vapor inside a glass tube. The mercury vapor emits ultraviolet (UV) rays when electric current passes through it. These UV rays strike the fluorescent coating on the inner surface of the glass tube, which then converts them into visible light.

In simple words, tube light meaning refers to a cylindrical-shaped lamp that works on the principle of gas discharge and fluorescence.

Components of Tube Light

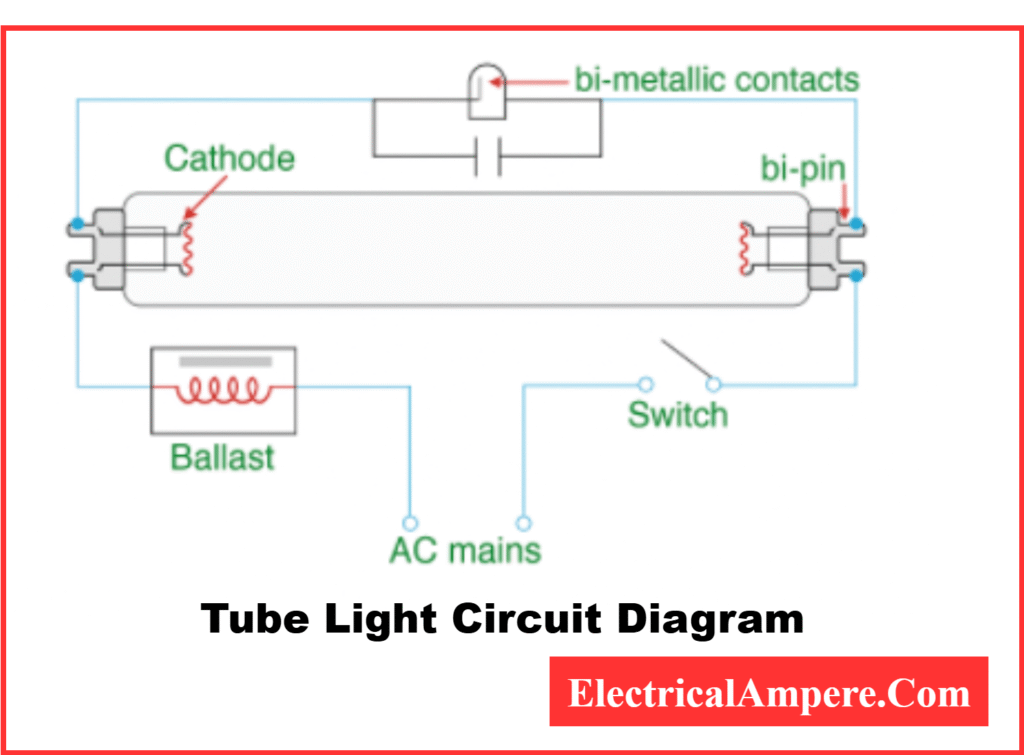

A tube light is made up of several essential parts that work together to produce light. Below are the tube light components:

- Glass Tube – A sealed cylindrical tube filled with low-pressure mercury vapor and inert gas like argon.

- Filament (Electrodes) – Tungsten filaments coated with emissive material placed at both ends of the tube.

- Starter – Provides initial surge of current to heat the filaments and start the discharge.

- Choke (Ballast) – A coil of wire that limits current flow and provides high voltage for starting.

- Fluorescent Powder Coating – Coating on the inner surface of the tube that converts UV rays to visible light.

- End Caps & Holders – Provide mechanical support and electrical connections.

So, the main parts of tube light include the tube, electrodes, starter, choke (ballast), and coating.

Auxiliary Electrical Components of Tube Light

A tube light cannot run directly from the power supply. It needs the help of auxiliary electrical components that assist in starting the lamp and regulating the flow of current. These components play a crucial role in ensuring that the tube light working process is smooth and efficient.

1. Ballast

The ballast is a device that controls the current flowing through the tube. Without it, the current would rise uncontrollably and damage the lamp.

- Electromagnetic Ballast: Uses a copper coil and iron core. It is reliable but consumes more energy and sometimes causes flickering.

- Electronic Ballast: A modern alternative that uses electronic circuitry to provide high-frequency supply. It is more efficient, eliminates flickering, and saves energy.

2. Starter

The starter is another important auxiliary part of tube light. It is a small glass bulb filled with gas, usually neon, with a bimetallic strip and a capacitor inside. When the tube light is switched on:

- The starter allows a brief flow of current to heat the filaments at both ends of the tube.

- After a moment, the bimetallic strip cools and breaks the circuit, causing a voltage surge from the ballast.

- This surge helps in ionizing the mercury vapor, which initiates the discharge inside the tube.

In short, the ballast and starter are essential tube light components that make the ignition process possible and ensure the lamp operates safely.

Working Principle of Tube Light

The working of tube light is based on the discharge of electrons through mercury vapor and the conversion of UV light into visible light.

Here’s the step-by-step tube light working process:

- Starting the Tube Light

- When the switch is turned on, current flows through the choke and starter.

- The starter contains a small gas-filled bulb with bimetallic strips that initially allow current to pass, heating the filaments at both ends of the tube.

- Ignition of Mercury Vapor

- The heating causes the filaments to emit electrons.

- The starter opens after a few seconds, causing a sudden high voltage surge from the choke.

- This surge ionizes the mercury vapor inside the tube.

- Emission of Ultraviolet Rays

- As the electrons flow through the ionized mercury vapor, it emits ultraviolet radiation.

- Conversion to Visible Light

- The UV rays strike the fluorescent powder coating on the inside of the glass tube.

- This coating absorbs UV rays and re-emits them as visible white light.

Thus, the working of tubelight involves electrical discharge, gas ionization, and fluorescence.

Types of Tube Light

Over the years, tube lights have evolved with improvements in technology. Today, you can find different kinds of tube lights designed for various needs. The main types of tube light are:

1. Conventional Fluorescent Tube Light

This is the most common and traditional form of tube light. It uses a choke (ballast) and a starter for operation.

- The ballast regulates the current and provides the voltage surge needed to start the lamp.

- The starter helps in preheating the filaments and initiating the discharge.

- These lights are affordable but may cause flickering and consume more power compared to modern options.

2. Electronic Ballast Tube Light

An advanced version of the conventional type, this tube light replaces the heavy choke with an electronic ballast.

- Provides a high-frequency supply, eliminating flicker.

- Reduces humming noise and improves energy efficiency.

- Lightweight and compact design compared to electromagnetic ballast.

- Often preferred in offices, schools, and homes for steady, comfortable lighting.

3. LED Tube Light

The LED tube light is the latest innovation in lighting technology. Unlike fluorescent tubes, it does not require a starter or ballast.

- Operates directly on the electric supply.

- Offers higher energy efficiency, longer lifespan (up to 50,000 hours), and brighter light output.

- Eco-friendly as it does not contain mercury.

- Gradually replacing fluorescent tube lights in homes, offices, and industries.

In short, the difference between LED tube light and fluorescent tube light lies in efficiency, lifespan, and ease of use. While conventional and electronic ballast types are still in use, LED tube lights are becoming the preferred choice worldwide.

Comparison: LED vs Fluorescent vs Electronic Ballast Tube Lights

| Feature | Conventional Fluorescent Tube Light | Electronic Ballast Tube Light | LED Tube Light |

| Starting Method | Needs choke and starter | Uses electronic ballast, no starter | Direct supply, no choke or starter |

| Energy Efficiency | Moderate (more power loss) | Better than conventional | Very high (up to 60% energy savings) |

| Flicker | Common issue | Reduced flicker | No flicker |

| Noise | May produce humming | Silent | Silent |

| Lifespan | 5,000–10,000 hours | 8,000–12,000 hours | 25,000–50,000 hours |

| Maintenance | Starter & choke may need replacement | Low maintenance | Very low maintenance |

| Eco-Friendliness | Contains mercury (toxic) | Contains mercury (toxic) | Mercury-free, eco-friendly |

| Cost | Low initial cost | Moderate cost | High initial cost but cost-effective long term |

Advantages & Disadvantages of Tube Light

Like any lighting technology, tube lights come with their own benefits and limitations. Understanding these helps in comparing them with modern alternatives like LED lights.

Advantages of Tube Light

- Bright and Uniform Light – Provides clear illumination, suitable for large rooms, offices, and study areas.

- Low Heat Emission – Unlike incandescent bulbs, tube lights produce very little heat, keeping rooms cooler.

- Cost-Effective – Affordable and widely available in the market.

- Long Life Span – Lasts much longer than traditional filament bulbs, typically 5,000–10,000 hours.

- Wide Coverage – Provides broad light distribution, ideal for larger spaces.

Disadvantages of Tube Light

- Contains Mercury – Fluorescent tube lights use mercury vapor, which is harmful to health and the environment if not disposed of properly.

- Needs Starter and Ballast – Requires auxiliary components, making installation slightly more complex.

- Flickering Issues – Older models with electromagnetic ballasts often flicker, which can strain the eyes.

- Less Efficient than LEDs – Consumes more power compared to LED tube lights with similar brightness.

- Maintenance Required – Starters and ballasts may need replacement over time.

Applications of Tube Light

Tube lights have been one of the most popular lighting solutions for decades because of their bright illumination, cost-effectiveness, and wide coverage area. They are suitable for both residential and commercial purposes. Below are the major applications of tube light:

- Homes and Offices – Tube lights are widely used in living rooms, study rooms, and office spaces because they provide uniform, glare-free lighting that is ideal for reading and working.

- Educational Institutions – Schools, colleges, and libraries use tube lights to ensure bright and consistent lighting, creating a comfortable environment for students.

- Hospitals and Clinics – Medical facilities require clean, bright, and reliable lighting for patient care and diagnosis, making tube lights a common choice.

- Factories and Workshops – Industrial areas need strong lighting for safety and precision in work. Tube lights are used in workshops, assembly lines, and warehouses.

- Commercial Buildings – Shopping malls, retail stores, and showrooms often use tube lights to highlight products and provide bright indoor lighting.

Common Problems in Tube Light and Their Solutions

Over time, tube lights may develop faults due to wear and tear of their components like the starter, choke, or filament. Here are some of the most common tube light problems and solutions:

1. Flickering Tube Light

- Cause: Usually happens because of a faulty starter or weak choke (ballast).

- Solution: Replace the starter first, as it is inexpensive and easy to change. If the issue continues, replace the choke.

2. Dim Light Output

- Cause: This may occur due to a weak ballast, reduced gas pressure inside the tube, or low mercury vapor.

- Solution: Check and replace the ballast if needed. If the tube is old, replacing it with a new one is the best solution.

3. Tube Light Not Glowing at All

- Cause: Possible reasons include a defective starter, broken filament, or internal tube failure.

- Solution: Inspect the starter and filaments. If damaged, replace them. In many cases, replacing the entire tube light is more practical.

4. Blackened Tube Ends

- Cause: Occurs when the filament coating wears out after prolonged use.

- Solution: This is a sign that the tube has reached the end of its lifespan. Replacing the tube light is the only fix.

By knowing these common issues in tube light and their solutions, users can quickly troubleshoot and maintain their lighting system without much hassle.

Environmental Impact & Disposal of Tube Light

While tube lights have been widely used for decades, they pose certain environmental concerns due to the materials inside them. Understanding their impact and proper disposal methods is important for both safety and sustainability.

Environmental Impact

- Contains Mercury – Tube lights use mercury vapor to produce ultraviolet rays. Mercury is toxic and harmful to humans, animals, and the environment if released.

- Risk of Pollution – Improper disposal can lead to mercury leakage into soil and water, causing long-term contamination.

- Energy Consumption – Though more efficient than incandescent bulbs, fluorescent tube lights still consume more electricity compared to modern LEDs.

Safe Disposal and Alternatives

- Proper Recycling – Tube lights should not be thrown in regular trash. They must be taken to authorized recycling centers that handle hazardous waste.

- Safe Handling – If a tube light breaks, avoid direct contact with glass and ventilate the area to reduce mercury exposure.

- Switch to LEDs – LED tube lights are mercury-free, consume less energy, and last much longer, making them an eco-friendly alternative.

In short, while tube lights are not directly harmful during normal use, their mercury content makes safe disposal essential. Replacing them with LED tube lights is a better choice for health, energy savings, and the environment.

Conclusion

In summary, tube light means a fluorescent lamp that works on the principle of gas discharge and fluorescence. Its essential components of tube light include the glass tube, electrodes, starter, choke, and fluorescent coating. The working principle of tubelight involves ionization of mercury vapor, emission of ultraviolet rays, and conversion into visible light through the fluorescent coating.

Understanding the tube light working process helps us appreciate why it became a preferred lighting solution for decades before the rise of LEDs.

Related Articles: