Learn about synchronous machine, its working principle, types, and applications. Understand how synchronous motors and generators operate in power systems for efficient energy conversion.

What is a Synchronous Machine?

A synchronous machine is an AC electrical machine that operates at a constant speed, known as synchronous speed, under steady-state conditions. It can function as both a synchronous motor and a synchronous generator (alternator). A machine that converts mechanical power into AC electrical power is called a Synchronous Generator or Alternator. However, when the same machine operates as a motor, it is known as a Synchronous Motor. These machines are widely used in power generation, industrial applications, and electrical drives.

Basic Principle of a Synchronous Machine

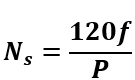

A synchronous machine works on the principles of electromagnetic induction and interaction of magnetic fields. It follows the fundamental relationship:

Where:

- Ns = Synchronous speed (RPM)

- f = Supply frequency (Hz)

- P = Number of poles

When functioning as a generator, it must rotate at synchronous speed to maintain a stable output frequency. As a motor, it must also sustain this speed; otherwise, it loses synchronization, leading to a condition called pulling out of step, where the machine ceases operation. This principle ensures the machine’s reliability in power generation and industrial applications. Since electrical appliances and machines are designed to function at this frequency, maintaining it is crucial. In some countries, the standard frequency is 50 Hz.

Types of Synchronous Machines

- Synchronous Generator (Alternator) – Converts mechanical power into AC electrical power.

- Synchronous Motor – Converts AC electrical power into mechanical power.

Working Principle of a Synchronous Machine

A synchronous machine is an electromechanical transducer that efficiently converts mechanical energy into electrical energy or vice versa. This conversion is governed by two fundamental principles: the Law of Electromagnetic Induction and the Law of Interaction.

A detailed explanation of these principles is provided below.

Law of Electromagnetic Induction

Also known as Faraday’s First Law of Electromagnetic Induction, this law explains the production of electromotive force (EMF). According to this principle, when a conductor moves through a magnetic field or cuts across magnetic field lines, an EMF is induced in it. This fundamental concept is essential in the operation of electrical machines, including generators and transformers. The figure below illustrates this principle.

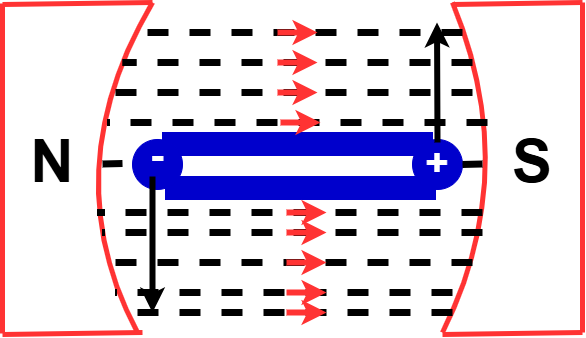

Law of Interaction

This law explains the generation of force or torque in electrical machines. When a current-carrying conductor is placed in a magnetic field, it experiences a force due to the interaction between the magnetic field produced by the conductor and the main field. This interaction results in the exertion of force on the conductor, leading to the production of torque in motors. The figure below illustrates this principle.

Three-Phase Synchronous Machines

Synchronous machines are widely used in both household and industrial applications. Small synchronous machines are found in appliances like air coolers, refrigerators, fans, and air conditioners. However, large AC machines are typically three-phase synchronous machines due to several advantages:

- For the same frame size, a three-phase machine delivers 1.5 times more output than a single-phase machine.

- Three-phase power transmission and distribution are more economical compared to single-phase power.

- Three-phase motors offer self-starting capability (except synchronous motors).

- They generate continuous uniform torque, while single-phase motors produce pulsating torque.

In small synchronous machines, the field winding is on the stator, and the armature winding is on the rotor. In contrast, large synchronous machines have the field winding on the rotor and the armature winding on the stator for better efficiency and performance.

Construction of a Synchronous Machine

- Stator (Armature Winding) – Produces the working voltage in large synchronous generators.

- Rotor (Field Winding) – Generates the main magnetic field, often excited by DC.

- Excitation System – Supplies DC to the rotor winding, maintaining synchronization.

Applications of Synchronous Machines

- Power plants (hydro, thermal, nuclear) for electricity generation.

- Industrial applications such as large compressors, pumps, and conveyors.

- Used in power factor correction and voltage regulation.

Conclusion

A synchronous machine is a crucial component in power systems, ensuring stable and efficient energy conversion. Understanding its principles and applications helps in optimizing its performance in various industries. These machines play a vital role in the reliable generation and utilization of electrical energy worldwide.

Useful Resource: Synchronous Motor- Wikipedia

Read Next: