Electric machines are at the heart of our modern world. Whether it is a ceiling fan in your home, an alternator in your car, or a giant generator in a power plant, they all belong to one family – rotating electrical machines. These machines plays important role in industrialization, automation, and electrifying almost every aspect of life.

A rotating electrical machine is a device that converts energy between electrical and mechanical forms through the principle of electromagnetic induction. The rotation of one part relative to another (stator and rotor) is the defining characteristic.

In this detailed guide, we’ll cover the general concept of rotating electrical machines, their structure, working, types, torques, speed regulation methods, applications, and recent advances.

General Concept of Rotating Electrical Machines

The general concept of rotating electrical machines revolves around three principles:

- Electromagnetic Induction (Faraday’s Law)

- Whenever a conductor cuts across magnetic flux, an EMF (Electromotive Force) is induced.

- If this conductor is part of a closed path, current flows, and energy transfer occurs.

- Lorentz Force

- A current-carrying conductor in a magnetic field experiences a force.

- This force is what produces torque in motors.

- Rotating Magnetic Field

- In AC machines, polyphase currents produce a rotating magnetic field in the air gap.

- The rotor locks into or follows this field, enabling continuous rotation.

Generators use motion (mechanical → electrical), while motors use current and field interaction (electrical → mechanical).

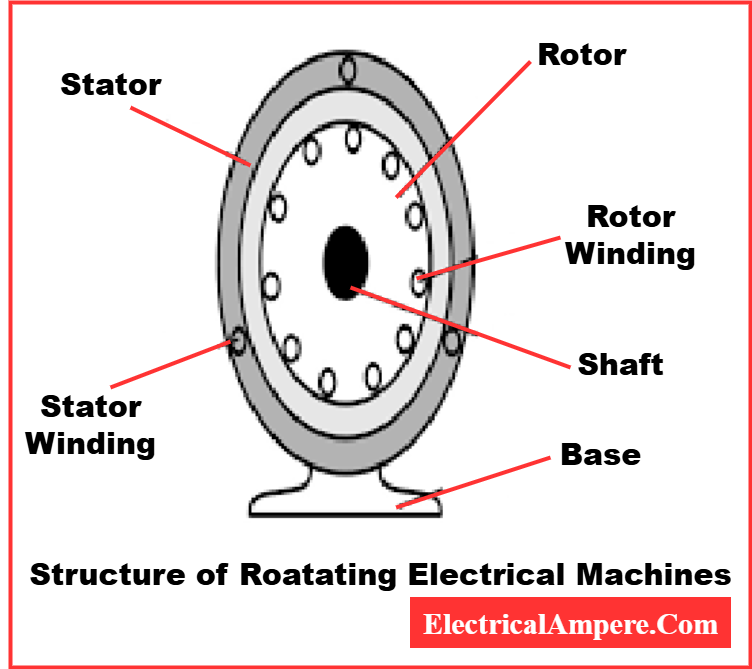

Basic Structure of Rotating Electrical Machines

Though machine sizes vary—from tiny micromotors to giant alternators weighing hundreds of tons—the basic structure of rotating electrical machines remains similar.

1. Stator (Stationary Part)

- Houses windings or permanent magnets.

- Provides the rotating magnetic field.

- Laminated steel construction minimizes eddy current losses.

- Slots are cut to hold copper windings.

2. Rotor (Rotating Part)

- Placed inside the stator.

- Carries conductors or windings.

- Types:

- Squirrel Cage Rotor (simple, rugged, common in induction motors).

- Wound Rotor (used for speed control).

- Salient Pole Rotor (projecting poles, used in hydro alternators).

- Cylindrical Rotor (smooth, used in turbo alternators).

3. Air Gap

- A small clearance between stator and rotor.

- Critical for flux transfer.

- Small gaps improve efficiency but must allow smooth rotation.

4. Bearings and Shaft

- Bearings support the rotor.

- The shaft transfers mechanical output (in motors) or mechanical input (in generators).

5. Cooling System

- Essential because machines generate copper loss (I²R), iron loss, and stray losses.

- Cooling methods: natural air, forced air, liquid cooling, or hydrogen cooling in large alternators.

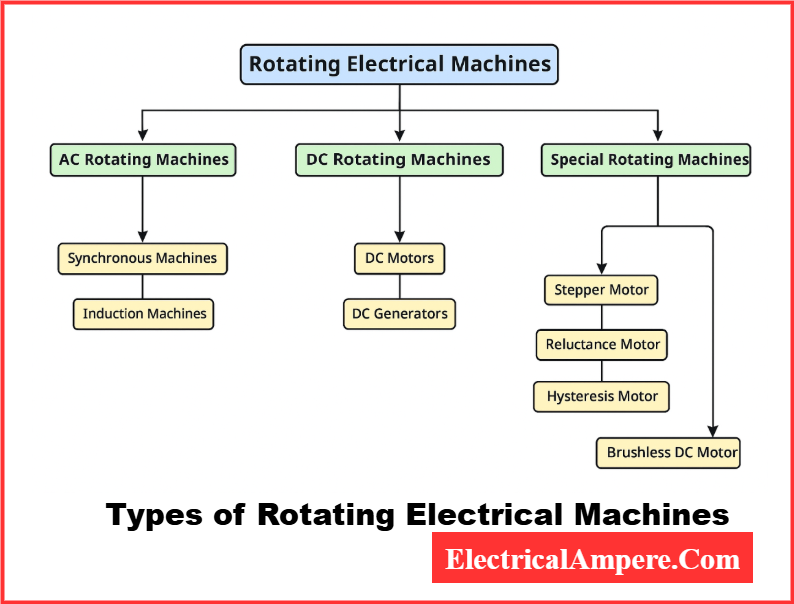

Types of Rotating Electrical Machines

The types of rotating electrical machines can be classified into three main categories:

1. AC Rotating Machines

(a) Synchronous Machines

- Run exactly at synchronous speed (Ns = 120f/P).

- Types:

- Alternator (Generator) – converts mechanical → electrical.

- Synchronous Motor – converts electrical → mechanical.

- Applications: power generation, high-precision drives, power factor correction.

Read detailed article on : Synchronous Machine

(b) Induction Machines

- Most widely used motors.

- Rotor never reaches synchronous speed.

- Types:

- Single-phase induction motor – used in fans, refrigerators.

- Three-phase induction motor – used in industries.

- Rugged, efficient, low-maintenance.

2. DC Rotating Machines

(a) DC Motors

- Types:

- Shunt Motor – nearly constant speed.

- Series Motor – very high starting torque.

- Compound Motor – combination of both.

- Used in traction, elevators, rolling mills.

(b) DC Generators

- Classified as shunt, series, or compound.

- Once common in power systems, now mostly used in laboratories and small-scale systems.

Read detailed article on: DC Machine- Definition, Basic structure, Construction & Equivalent circuit

3. Special Rotating Machines

- Stepper Motor – rotates in discrete steps, used in robotics.

- Brushless DC Motor (BLDC) – efficient, low noise, used in drones and EVs.

- Switched Reluctance Motor (SRM) – robust and high torque, used in electric vehicles.

- Universal Motor – runs on both AC and DC, used in mixers and drills.

Comparison Table of Rotating Electrical Machines

| Parameter | DC Machine | Synchronous Machine | Induction Machine |

| Type | DC Motor / DC Generator | Synchronous Motor / Alternator | Induction Motor / Generator |

| Power Supply | DC Supply | AC Supply (constant frequency) | AC Supply |

| Rotor Speed | Varies with load and voltage | Constant (synchronous speed) | Less than synchronous speed (slip) |

| Starting | Requires starter | Needs external means to start | Self-starting |

| Construction Complexity | Complex (commutator and brushes) | Complex (field winding and slip rings) | Simple and rugged |

| Maintenance | High (brushes and commutator) | Moderate | Low |

| Efficiency | Moderate to high | High | Moderate to high |

| Cost | Expensive | Expensive | Cheap |

| Applications | Traction, steel mills, variable speed drives | Power generation, synchronous condensers, constant-speed drives | Pumps, fans, compressors, general-purpose drives |

Rotating Machines Examples

Here are some rotating machines examples from daily life and industry:

- Household – Fans, washing machines, mixers, refrigerators.

- Automobile – Car alternator, wiper motor, starter motor.

- Power Generation – Hydro generators, thermal alternators, wind turbine generators.

- Industry – Induction motors in pumps, conveyors, compressors, cranes.

- Transportation – Electric train traction motors, metro drives.

Rotating Electrical Machines List

A complete rotating electrical machines list includes:

- DC Motor

- DC Generator

- Synchronous Motor

- Alternator (Synchronous Generator)

- Single-phase Induction Motor

- Three-phase Induction Motor

- Stepper Motor

- Brushless DC Motor (BLDC)

- Universal Motor

- Switched Reluctance Motor (SRM)

- Servo Motor

This list shows how versatile rotating machines are across industries.

Rotating Magnetic Field

The concept of the rotating magnetic field is central to AC machines.

- Created by applying a three-phase AC supply to stator windings.

- Produces a rotating magnetic flux.

- The synchronous speed is given by:

Ns=120f/P

where:

- f = frequency of supply,

- P = number of poles.

The rotor tries to chase this field, producing torque. This principle powers almost every induction motor and alternator.

Machine Torques

The torque generated in rotating machines enables useful work.

1. Electromagnetic Torque

- Generated due to interaction between current-carrying rotor conductors and magnetic flux.

- Formula:

Te=k⋅ϕ⋅Ia

where ϕ = flux, Ia = armature current.

2. Reluctance Torque

- Produced when the rotor aligns itself with the minimum reluctance path.

- Basis of operation in reluctance motors, stepper motors.

3. Starting Torque

- Important in motors like elevators and traction where heavy loads must start from rest.

4. Pull-out Torque (in synchronous machines)

- Maximum torque a synchronous motor can deliver without losing synchronism.

Speed Control of Rotating Machines

Speed Control is critical for performance and safety.

DC Machines:

- Field Control Method – vary flux to change speed.

- Armature Voltage Control – change applied voltage.

- Resistance Control – add resistance in armature circuit.

Read Detailed article on: Speed Control Methods of DC Motor – Armature, Flux & Voltage Control Explained

Induction Motors:

- Pole Changing – change stator poles.

- Rotor Resistance Control – insert external resistance.

- Frequency Control – modern method using Variable Frequency Drives (VFDs).

Synchronous Machines:

- Speed fixed by supply frequency.

- Controlled indirectly by varying input frequency.

Good speed regulation of rotating machines ensures stability, efficiency, and long machine life.

Applications of Rotating Electrical Machines

Rotating machines are the workhorses of modern civilization. Their applications include:

- Power Generation

- Alternators in hydro, thermal, nuclear, and wind plants.

- Industrial Sector

- Motors in pumps, compressors, conveyors, rolling mills, cranes.

- Transportation

- Traction motors in trains, metros, EVs.

- Domestic Use

- Fans, refrigerators, washing machines, vacuum cleaners.

- Healthcare

- Motors in medical devices like ventilators, centrifuges.

- Defense & Aerospace

- High-precision servo motors in aircraft and satellites.

Recent Advances in Rotating Electrical Machines

Technology is revolutionizing rotating machines. Recent advances include:

- High-Efficiency Motors – Designed with advanced magnetic materials and optimized windings.

- Brushless Designs – BLDC and PMSM motors with longer lifespan.

- IoT and Smart Monitoring – Machines with sensors for predictive maintenance.

- Compact High-Torque EV Motors – Permanent magnet and reluctance-based drives for electric vehicles.

- Superconducting Machines – Zero resistance windings for specialized high-power applications.

- Renewable Energy Generators – Wind turbine alternators with variable speed technology.

These advances make machines more efficient, compact, and environmentally friendly.

Conclusion

Rotating electrical machines are the backbone of modern industry, transport, and power generation. From the ceiling fan in your room to giant power station alternators, they surround us everywhere.

We explored the general concept of rotating electrical machines, their structure, types, examples, torque mechanisms, speed control methods, applications, and recent advances. With new developments in smart technologies, renewable energy, and electric mobility, rotating machines will continue to evolve and play an even bigger role in the future.

Related Articles: