Motor unbalance is a critical issue in electrical engineering, particularly in industrial environments where motors are extensively used. It refers to an unequal distribution of electrical or mechanical forces within a motor. This can lead to reduced efficiency, overheating, increased vibration, and even permanent damage to the motor over time.

Unbalance and imbalance terms mean the same in electrical practice. “Unbalance” is used in NEMA and IEC standards, while “imbalance” is a general word used by engineers in field operations.

Motor unbalance can occur in three-phase motors, which are widely used for industrial applications, and can manifest as electrical unbalance, mechanical unbalance, or a combination of both.

Understanding motor current unbalance, its causes, effects, and how to calculate it using the motor unbalance formula is essential for engineers and maintenance personnel.

Types of Motor Unbalance

Motor imbalance can be broadly categorized into electrical and mechanical types. Both types significantly affect motor performance.

Electrical Unbalance

Electrical unbalance occurs when the electrical supply to the motor is uneven. It can be detected in motor current unbalance or voltage fluctuations across the three phases.

- Voltage Unbalance:

Voltage unbalance happens when the voltages or phase angles across the three phases (R, Y, B) are unequal. This can lead to inefficient motor operation, overheating, and even insulation failure. - Current Unbalance:

Current unbalance occurs when the current in each phase differs. Imbalance current in a 3-phase motor can be caused by:- Unequal supply voltage

- Faulty or loose electrical connections

- Uneven loading across phases

Motor unbalance in three-phase motors can increase energy consumption and reduce efficiency. Detecting this early prevents expensive downtime.

Mechanical Unbalance

Mechanical unbalance arises from physical issues in the motor’s rotating parts. Common causes include:

- Uneven rotor mass distribution

- Bent or misaligned shaft

- Loose or damaged components

- Dust, dirt, or material buildup on rotating parts

Mechanical unbalance increases vibration, produces noise, and accelerates wear on bearings and couplings.

What Causes Current Unbalance in Motors?

Current unbalance is a frequent issue in three-phase motors. Some major causes include:

- Electrical Causes:

- Uneven load distribution across phases

- Loose or corroded terminal connections

- Faulty fuses, circuit breakers, or damaged conductors

- Voltage fluctuation or loss of phase in the supply system

- Mechanical Causes:

- Rotor misalignment or bending

- Unequal mass distribution on rotating components

- Worn bearings or couplings

- Residue buildup or imbalance after motor repairs

If ignored, current imbalance leads to overheating, insulation damage, and reduced motor life.

Effects of Motor Unbalance

Motor imbalance affects both mechanical and electrical aspects of the motor.

Mechanical Effects

- Excessive vibration and mechanical stress on bearings and shafts

- Premature failure of mechanical components

- Increased noise and vibrations, reducing operational comfort

- Misalignment of connected machinery

Electrical and Thermal Effects

- Higher I²R losses, causing stator winding overheating

- Reduced torque and efficiency

- Shortened motor lifespan due to insulation degradation

- Harmonics and electromagnetic interference (EMI)

- Erratic motor operation or trips

Regular monitoring of motor current unbalance is essential to prevent these issues.

Motor Unbalance Formula and Calculation

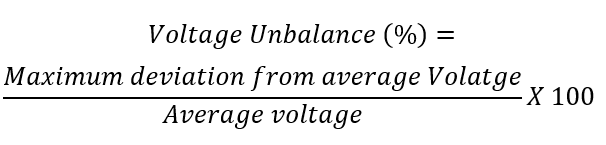

Voltage Unbalance Formula

The voltage unbalance percentage is calculated as:

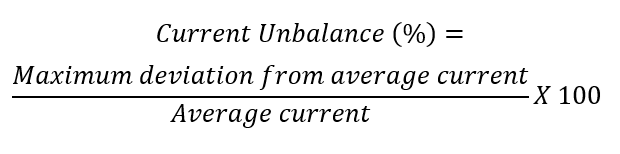

Current Unbalance Formula

Similarly, current unbalance is calculated as:

Example: Motor Unbalance Current Calculation

If a 3-phase motor has line currents of 42 A, 40 A, and 36 A:

- Average current = (42 + 40 + 36) / 3 = 39.3 A

- Maximum deviation = 42 – 39.3 = 2.7 A

Current Unbalance=2.739.3×100=6.87%

The motor current unbalance is approximately 6.9%.

Maximum Allowable Current Unbalance in Three-Phase Systems

The maximum allowable current unbalance in three-phase motors is standardized by NEMA MG-1:

- Ideal: < 2–3%

- Maximum permissible: 10%

Exceeding this can lead to:

- Reduced efficiency

- Overheating and insulation failure

- Shortened motor lifespan

Keeping unbalance low ensures smooth operation and reduces maintenance costs.

Detection and Prevention of Motor Unbalance

Monitoring

- Install sensors to measure current in each phase

- Use a Current imbalance Calculator or motor protection relay for automatic detection

Regular Maintenance

- Tighten loose connections and terminals

- Clean motor components to avoid mechanical imbalance

- Inspect bearings and rotor alignment

Load Balancing

- Distribute loads evenly across all three phases

- Avoid single-phase loading that causes phase current differences

Protection Systems

- Motor protection relays detect phase imbalance and can shut down the motor to prevent damage

- Alarms alert operators to take corrective action

Dynamic Balancing

- For mechanical imbalance, perform dynamic field balancing after motor repairs

- This reduces vibrations and extends motor life

Practical Tips for Reducing Motor Unbalance

- Always measure phase currents after installation and maintenance

- Schedule preventive maintenance to check for loose connections or worn components

- Use protective relays that monitor both voltage and current unbalance

- Train operators to identify early signs of vibration or noise

Key Takeaways

- Motor unbalance in three-phase motors can be electrical, mechanical, or both.

- Motor current unbalance is often caused by voltage variations, loose connections, or uneven load distribution.

- Keeping imbalance below 2–3% ensures motor reliability and energy efficiency.

- Use the motor unbalance formula or a Current Unbalance Calculator to detect and correct issues early.

Proactive detection and correction of motor imbalance can save energy, reduce downtime, and extend motor life.

Related Articles: