When you work with electrical systems, you must ensure the insulation quality for safety and performance. Insulation resistance plays a key role in evaluating the condition of insulation in cables, transformers, motors, and other equipment.

In this article, you will learn the basics of insulation resistance(IR), how to measure it, the formulas involved, typical test values, and answers to common questions like “What is an IR value?” and “How do you measure IR?”

What is Insulation Resistance?

Insulation resistance shows how much an insulating material resists the flow of electric current. It indicates how well insulation blocks leakage currents and protects your electrical system from faults or failures.

In simple terms, it measures how effectively insulation stops electricity from escaping through unwanted paths. High insulation resistance(IR) means good insulation quality. On the other hand, low resistance signals problems like moisture, dirt, or damage.

Insulation Resistance Formula

You can measure insulation resistance using a megohmmeter—commonly referred to as performing a megger test—or other insulation testers.

The basic formula to calculate insulation resistance (IR) is:

R=V/I

Where:

- R is Insulation Resistance (Ohms, usually Megaohms, MΩ)

- V is the Applied Test Voltage (Volts)

- I is the Leakage Current through insulation (Amperes)

This formula applies Ohm’s law to leakage current: dividing the voltage by the current gives the insulation resistance.

Example: If a test voltage of 500 V is applied and the measured leakage current is 0.5 mA:

R=5000/0.0005

R=1 MΩ

So, the resistance of the insulating material is 1 MΩ.

Units of Insulation Resistance

The primary unit used to measure insulation resistance(IR) is the megaohm (MΩ). Since IR values are usually very high, they are often expressed in megaohms, and sometimes even in larger units like gigohms (GΩ) or teraohms (TΩ) for extremely high resistance levels.

In some cases, IR is also represented as a CR product—for example, in units like MΩ·µF. This product combines the insulation resistance (in megaohms) with the capacitance (in microfarads) and helps in evaluating the overall condition of insulation systems.

How Do You Measure Insulation Resistance?

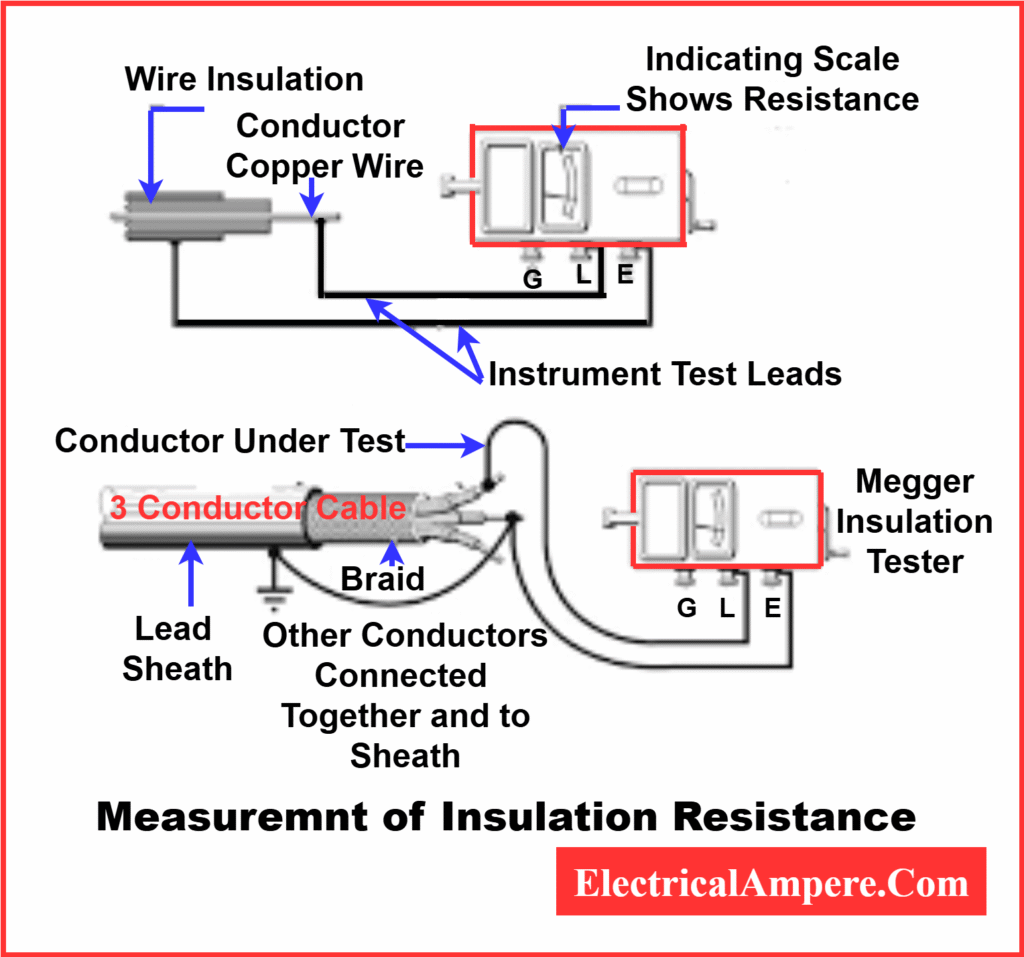

Follow these steps for measurement of insulation resistance:

- Disconnect power from the equipment or circuit to be tested.

- Connect the megohmmeter leads: one to the conductor and one to the insulation or ground.

- Apply a test voltage (commonly 500V, 1000V, or higher, depending on the equipment rating).

- Measure the leakage current flowing through the insulation.

- The tester calculates and displays the IR in megaohms (MΩ).

The higher the measured insulation resistance, the better the insulation condition.

Typical Insulation Resistance Test Values

What are minimum acceptable or normal insulation resistance values? These can vary depending on the type of equipment, voltage level, and age. However, general guidelines are:

- New electrical equipment: Greater than 100 MΩ is considered excellent.

- Used equipment: Minimum acceptable values typically range from 1 MΩ to 50 MΩ.

- Values below 1 MΩ often indicate faulty or deteriorated insulation requiring maintenance.

Note: These values can vary depending on the voltage level, equipment type, and applicable standards or regulations. Always refer to manufacturer guidelines or relevant industry standards for precise limits.

Minimum Insulation Resistance Value Acceptable Formula

The minimum acceptable insulation resistance for electrical equipment and circuits is usually calculated using a formula that relates resistance to the equipment’s rated voltage and sometimes its power rating.

For example, in rotating machines like motors, a common formula is:

IR=(kV+1) MΩ

Where IR is the insulation resistance in megaohms and kV is the rated voltage in kilovolts.

Example:

For a motor with a rated voltage of 0.4 kV (400 volts), the minimum acceptable IR would be:

IR=(0.4+1)=1.4 MΩ

This means the insulation resistance should be at least 1.4 megaohms for safe and reliable operation.

What Does IR Value Mean?

The term IR value stands for Insulation Resistance value. It is simply the numerical reading obtained during an IR test and is expressed in megaohms (MΩ). This value helps assess insulation quality and detect problems before equipment failure occurs.

Read detailed article on: What is an IR Value of Electrical Equipment ?

Units: What Insulation Resistance is Measured In

Insulation resistance is commonly measured in ohms (Ω), but since insulation resistance is usually very high, the unit megaohms (MΩ) is preferred:

- 1 MΩ = 1,000,000 Ω

For most electrical insulation tests, readings are in the range of megaohms to gigohms.

Common Causes of Insulation Failure

Insulation failure can lead to equipment damage, safety hazards, and costly downtime. Understanding the main causes of insulation deterioration helps you prevent problems and extend equipment life. Some typical causes include:

- Mechanical Damage:

Physical impacts, abrasion, bending, or crushing can damage insulation materials, creating cracks or breaks. - Aging:

Over time, insulation materials naturally degrade due to environmental exposure and electrical stress, losing their insulating properties. - Chemical Exposure:

Contact with oils, solvents, acids, or other chemicals can break down insulation materials, causing them to weaken or become brittle. - UV Radiation:

Prolonged exposure to sunlight or UV light can degrade insulation, especially in outdoor applications, leading to cracking and reduced effectiveness. - Electrical Stress:

High voltages, surges, or partial discharges can cause electrical breakdown of insulation, creating pathways for leakage currents.

By recognizing these risks, you can take preventive measures such as regular inspection, proper handling, and using suitable insulation materials for your specific application.

Why is Measuring Insulation Resistance Important?

- Prevents electrical shock hazards by ensuring insulation integrity.

- Avoids equipment damage and downtime by detecting insulation faults early.

- Improves system reliability and efficiency.

- Complies with safety standards and regulations.

Regular IR testing is part of preventive maintenance in electrical installations.

Method of Measuring Insulation Resistance

Insulation resistance of electrical equipment can be measured using different types of instruments, including:

- Direct-indicating ohmmeter with hand-driven DC generator – Commonly referred to as a hand-driven megger, named after one of the most well-known manufacturers of such instruments.

- Direct-indicating ohmmeter with motor-driven DC generator – Often called a motorized megger.

- Direct-indicating ohmmeter with a built-in battery – Operates independently using its internal power source.

- Direct-indicating ohmmeter with built-in rectifier – Powered from an external AC supply.

- Resistance bridge circuit with built-in galvanometer and battery – Uses a bridge method for precise insulation resistance measurement.

Factors That Affect Insulation Resistance

Several factors can impact electrical insulating resistance in electrical equipment. Understanding these ensures accurate testing and effective maintenance.

- Material Degradation

Over time, insulation materials break down due to heat, moisture, chemical exposure, and aging. This degradation lowers resistance and increases the risk of electrical faults. - Moisture and Contamination

Moisture, dust, and dirt can collect on or penetrate insulation surfaces. These contaminants create conductive paths that reduce resistance, potentially causing leakage currents or short circuits. - Temperature

Temperature changes affect insulation’s electrical properties. Generally, higher temperatures decrease resistance of the electrical insulating materials because heat increases material conductivity. This causes test results to vary with temperature.

Safety Tips for Insulation Resistance Testing

Testing electrical insulating resistance involves working with electrical equipment and high test voltages, so safety is critical. Follow these tips to protect yourself and your equipment:

- Always Disconnect Power

Before starting any IR test, make sure the equipment or circuit is completely powered off and isolated to prevent electric shock or damage. - Use Proper Personal Protective Equipment (PPE)

Wear insulated gloves, safety glasses, and other necessary protective gear to minimize the risk of electrical hazards. - Verify Test Equipment Condition

Inspect your megohmmeter before use, especially if you plan to conduct a megger test, as damaged instruments can give inaccurate readings or cause safety issues. - Follow Manufacturer Instructions

Always adhere to the test instrument’s guidelines and recommended procedures to ensure accurate and safe testing. - Choose the Correct Test Voltage

Use the appropriate test voltage based on the equipment’s rating. Applying too high a voltage can damage insulation, while too low a voltage may produce unreliable results. - Keep the Test Area Dry and Clean

Moisture or dirt around the test area can affect the results and increase the risk of accidental shocks. Maintain a clean, dry workspace. - Beware of Stored Energy

Some equipment, like capacitors, can hold charge even after power is disconnected. Discharge such components safely before testing. - Avoid Touching Test Leads During Measurement

Do not touch the test leads or terminals during testing, as high voltages may be present. - Record and Compare Results Carefully

Always log your measurements and compare them to previous baseline readings or manufacturer limits. This helps track insulation condition over time and spot developing issues early.

Advanced Insulation Resistance Testing Techniques

Beyond the basic IR test, several advanced methods help provide a deeper assessment of insulation health:

- Polarization Index (PI) Testing:

This method measures IR over a longer period, typically 10 minutes, and compares it to the resistance after the first minute. The ratio helps identify moisture, contamination, or deterioration inside the insulation that short tests might miss. - Dielectric Absorption Ratio (DAR):

Similar to PI testing but uses a shorter time frame (usually 1 minute to 30 seconds). DAR helps detect insulation problems like contamination and aging by analyzing how insulation absorbs and retains charge. - Step Voltage Testing:

In this test, increasing voltage levels are applied step-by-step to the insulation while measuring leakage current. It helps reveal weaknesses that might only appear at higher voltages, providing a better indication of insulation strength.

These advanced techniques offer more detailed insights than standard IR tests, enabling better maintenance decisions and preventing unexpected failures.

Read detailed article: PI and DAR Test for Transformers and Motors – Formulas & Acceptable Values

IEC Standard for Testing Resistance of Insulating Material

The IEC standard for testing the resistance of insulating material is IEC 60270. This standard specifies the equipment, procedures, and acceptable resistance levels for evaluating electrical systems and components.

It ensures reliable and consistent measurements by defining test voltage values, ambient conditions like temperature and humidity, and minimum resistance requirements.

Final Tips for Accurate Insulation Resistance Testing

- Always disconnect power before testing.

- Use the appropriate test voltage for the equipment.

- Perform tests in a dry, clean environment to avoid misleading low values.

- Interpret results considering temperature and humidity.

- Compare readings to manufacturer specifications or baseline data.

Conclusion

Insulation resistance plays a crucial role in ensuring the safety, reliability, and efficiency of electrical systems. Regular testing and monitoring help detect insulation deterioration early, preventing equipment failure and electrical hazards.

By understanding the key concepts, measurement techniques, and factors affecting IR, you can maintain your electrical equipment in optimal condition.

Always follow proper safety practices and use the right tools—whether you’re doing a quick check or a full megger testing—to get accurate results.

Related Articles: