Electric machines are the building blocks of modern civilization. They convert, control, and distribute energy, making it possible to run industries, transportation systems, and even household gadgets. From the alternators in power plants to the tiny motors inside your smartphone vibrator, electric machines are everywhere.

This guide provides a complete explanation of electric machines—their definition, working, classification, list, formulas, examples, applications, and even their role in future technologies.

What is an Electric Machine?

An electric machine is any device that transforms energy from one form to another. In most cases, it deals with the conversion between electrical energy and mechanical energy or modifies electrical energy itself.

In simple words:

- Motors → Electrical energy → Mechanical energy

- Generators → Mechanical energy → Electrical energy

- Transformers → Electrical energy → Electrical energy (with changed voltage/current levels)

These machines are used in factories, power plants, transportation, healthcare, and homes, making them essential for both industrial growth and everyday comfort.

Types of Electric Machines

Electric machines are classified into three main categories: motors, generators, and transformers. Additionally, they can be classified as static or dynamic machines based on whether they have moving parts.

- Static Machines: Do not have moving parts. Example: Transformers, Capacitors.

- Dynamic Machines: Have moving parts. Example: Motors, Generators.

1. Motors (Electrical → Mechanical)

Motors are the most commonly used machines because almost every system needs motion. The main function of a motor is to convert electrical energy into mechanical energy, which can then be used to drive loads such as fans, pumps, conveyors, or vehicles.

Types of motors:

- DC Motor – Provides good speed control, used in EVs and robotics.

- Induction Motor (AC Motor) – Rugged, reliable, and widely used in fans, pumps, elevators.

- Synchronous Motor – Runs at a constant speed, ideal for power factor correction and precision devices.

- Stepper Motor – Used in printers, CNC machines, and robotics for precise step-by-step motion.

- Universal Motor – Works on both AC and DC, used in home appliances like mixers and drills.

- Brushless DC Motor (BLDC) – High efficiency, used in drones, EVs, and cooling fans.

Working principle of a motor:

Motors work on the principle of the Lorentz force, where a current-carrying conductor placed in a magnetic field experiences a force, producing motion.

2. Generators (Mechanical → Electrical)

Generators are responsible for producing electricity from mechanical energy sources such as turbines, engines, or flowing water.

Types of generators:

- DC Generator – Produces direct current, limited applications today.

- Alternator (AC Generator) – Produces alternating current, used in power plants, wind turbines, and cars.

- Synchronous Generator – Used in hydro and thermal power stations.

- Portable Generators – Backup power supply for homes and offices.

Working principle of a generator:

Generators operate on Faraday’s Law of Electromagnetic Induction: when a conductor cuts through a magnetic field, an electromotive force (EMF) is induced.

3. Transformers (Electrical → Electrical)

Transformers do not produce mechanical motion but play a vital role in power systems by stepping up or stepping down voltage.

Types of transformers:

- Power Transformer – Used in transmission networks for high voltage.

- Distribution Transformer – Supplies low voltage to homes and small industries.

- Current Transformer (CT) – Used in measuring and protection systems.

- Potential Transformer (PT) – Steps down voltage for measurement.

- Isolation Transformer – Provides safety and electrical separation.

Working principle of a transformer:

Transformers work on mutual induction, where alternating current in one coil induces a voltage in another coil through a magnetic field.

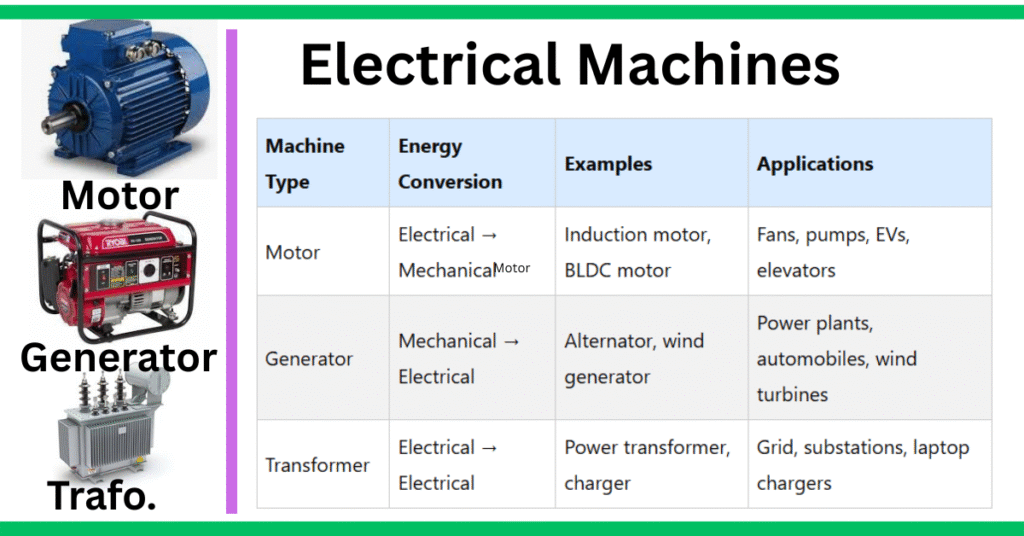

Comparison Table of Electric Machines

| Machine Type | Energy Conversion | Examples | Applications |

| Motor | Electrical → Mechanical | Induction motor, BLDC motor | Fans, pumps, EVs, elevators |

| Generator | Mechanical → Electrical | Alternator, wind generator | Power plants, automobiles, wind turbines |

| Transformer | Electrical → Electrical | Power transformer, charger | Grid, substations, laptop chargers |

Electrical Machines List

Here’s a broader list of electrical machines:

- DC Motor

- Induction Motor

- Synchronous Motor

- Stepper Motor

- Universal Motor

- BLDC Motor

- Alternator

- DC Generator

- Power Transformer

- Distribution Transformer

- Instrument Transformer

- Isolation Transformer

- Servo Motor

- Linear Motor

Electrical Machines Examples in Real Life

To make it practical, here are examples of electric machines in daily use:

- Ceiling Fan → Induction motor

- Laptop Charger → Transformer

- Car Alternator → Generator

- Metro Trains → High-power traction motors

- Wind Turbine → Generator producing renewable electricity

- Washing Machine → Universal motor

- Electric Scooter → BLDC motor

- MRI Machine → Uses motors and transformers

Electrical Machine Formulas

A few important formulas used in the study of electric machines are:

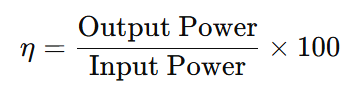

1. Efficiency of a Machine

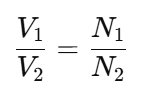

2. Transformer Turns Ratio

Where:

- V1 = Primary voltage (input side)

- V2= Secondary voltage (output side)

- N1 = Number of turns in the primary winding

- N2 = Number of turns in the secondary winding

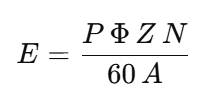

3. EMF Equation of a Generator

Where:

- E = Induced EMF (Volts)

- P = Number of poles of the generator

- Φ = Flux per pole (Weber)

- Z = Total number of conductors

- N = Rotational speed of the generator (RPM)

- A = Number of parallel paths in the armature winding

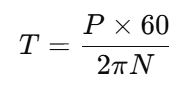

4. Motor Torque Formula

Where:

- T = Torque (in Newton-meters, N·m)

- P = Power output of the motor (in Watts)

- N = Speed of the motor (in revolutions per minute, RPM)

- π = Constant (3.1416)

5. Power in Three-Phase Machines

Where:

- P = Total three-phase power (Watts)

- VV = Line voltage (Volts)

- I = Line current (Amperes)

- cosϕ = Power factor

Energy-Efficient Electric Machines

Energy-efficient machines are designed to consume less electrical energy while delivering the same performance as standard machines. They help in reducing electricity bills, lowering carbon footprint, and improving system reliability.

Examples:

- IE3/IE4 Motors – High-efficiency induction motors used in industries and HVAC systems.

- BLDC Motors – Brushless DC motors in electric vehicles and drones.

- High-Efficiency Transformers – Low-loss transformers in power distribution.

- Servo Motors with Energy Recovery – In robotics and automation systems.

Benefits:

- Lower energy consumption

- Reduced operational cost

- Less heat generation and wear

- Compliance with energy regulations (like IEC, NEMA, or Indian BIS standards)

Applications:

- Industrial drives and conveyor systems

- Household appliances like fans, pumps, and refrigerators

- Electric vehicles and traction systems

- Renewable energy systems

Applications of Electric Machines

Electric machines are used everywhere:

1. Industrial Applications

- Motors run conveyor belts, compressors, pumps, and robotic arms.

- Generators provide electricity during outages.

2. Power Generation & Transmission

- Alternators generate electricity in power plants.

- Transformers step up voltage for transmission and step down for distribution.

3. Transportation

- Electric trains, elevators, trams, and EVs rely on motors.

- Aircraft alternators power on-board electrical systems.

4. Household Applications

- Fans, refrigerators, washing machines, and mixers.

- Chargers and adapters (transformers).

5. Medical Field

- X-ray machines, MRI scanners, and dialysis equipment.

Advantages of Electric Machines

- High efficiency and reliability

- Scalable – from tiny motors to massive power generators

- Environment-friendly with renewable energy sources

- Lower maintenance compared to mechanical systems

- Essential for automation and smart systems

Challenges and Limitations

While electric machines are highly beneficial, they also face challenges:

- High initial cost for large machines

- Maintenance needed for rotating machines (bearings, brushes)

- Losses in the form of heat (iron and copper losses)

- Transformers are bulky for low-frequency operation

Future of Electric Machines

The future is moving towards smarter and greener electric machines:

- Smart Motors with IoT Sensors – Predictive maintenance for industries

- High-Efficiency Generators – Designed for renewable sources like wind and hydro

- Compact Transformers – For smart grids and EV charging stations

- Lightweight Motors – For drones, robotics, and electric vehicles

- Superconducting Machines – With nearly zero losses

Conclusion

An electric machine is not just a piece of hardware—it is the engine of progress. From the smallest gadget to the largest power plant, electric machines ensure that energy is generated, transmitted, and utilized efficiently.

By learning their definition, history, types, formulas, list, and applications, we can better appreciate their importance in everyday life and in shaping our future.

The next era of electric machines will focus on efficiency, sustainability, and smart integration, making them even more critical for renewable energy, electric mobility, and advanced industries.

Related Articles: