An APFC Panel (Automatic Power Factor Correction Panel) is an automatic system that improves the power factor of electrical installations. It monitors the load and switches capacitor banks as needed to maintain efficient power usage. By optimizing reactive power, the APFC panel reduces energy losses, prevents utility penalties, and ensures smooth operation of electrical equipment.

What is APFC Panel?

The full form of APFC is Automatic Power Factor Correction. An APFC panel is an electrical device used to automatically improve the power factor of an electrical system. Power factor (PF) is the ratio of real power (kW) to apparent power (kVA) in a system. A low power factor indicates inefficient utilization of electrical power, leading to higher electricity bills and possible penalties from utility companies.

The APFC panel continuously monitors the power factor of the system and automatically switches capacitor banks ON or OFF to maintain the desired power factor, usually close to 0.95–0.99.

Working Principle of APFC Panel

The APFC panel works on a fully automatic principle using microcontrollers, relays, or contactors. Here’s how it works:

- The panel continuously measures the voltage, current, and power factor of the system.

- When the power factor falls below the preset value, the controller activates the capacitor banks through relays or contactors.

- Capacitors supply reactive power (kVAR) to the system, improving the power factor.

- Once the power factor reaches the desired value, the controller disconnects unnecessary capacitor banks to avoid overcompensation.

- This automatic operation prevents manual intervention and maintains an optimum power factor at all times.

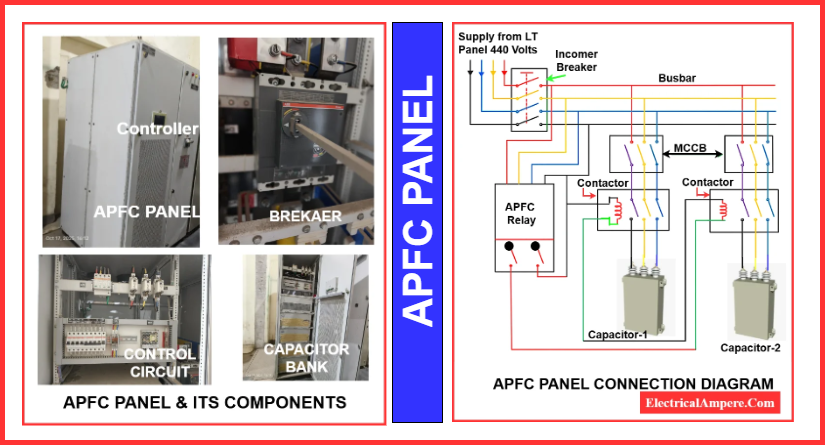

Components of an APFC Panel

An APFC (Automatic Power Factor Correction) panel is made up of several components that work together to improve the power factor automatically. Here’s a breakdown:

- Contactor/Relay

- Switches the capacitor banks ON or OFF automatically.

- Operates based on signals from the controller.

- Ensures safe connection of capacitors to the load.

- Capacitor Banks

- Provide reactive power (kVAR) to improve the power factor.

- Connected in parallel with the load.

- Multiple banks allow gradual correction and avoid overcompensation.

- Controller/Microcontroller

- Monitors voltage, current, and power factor continuously.

- Controls the contactors to switch capacitors as needed.

- Prevents frequent switching with time-delay features.

- Indicating Lamps

- Show which capacitor banks are ON or OFF.

- Help operators quickly check the panel’s status.

- Fuses or MCCBs

- Protect the panel and capacitors from short circuits or overcurrent.

- Each capacitor bank may have its own protection for safety.

- Current Transformers (CTs)

- Measure load current safely.

- Send a scaled-down current signal to the controller.

- Help the controller decide how many capacitor banks to switch.

- Optional Components

- Voltage Transformers (VTs): Measure voltage accurately.

- Surge Protection Devices (SPDs): Protect against voltage spikes.

- Digital Meters/Displays: Show real-time readings like voltage, current, kVAR, kW, and power factor.

These components work together to automatically maintain a healthy power factor, improve efficiency, and protect the electrical system from faults.

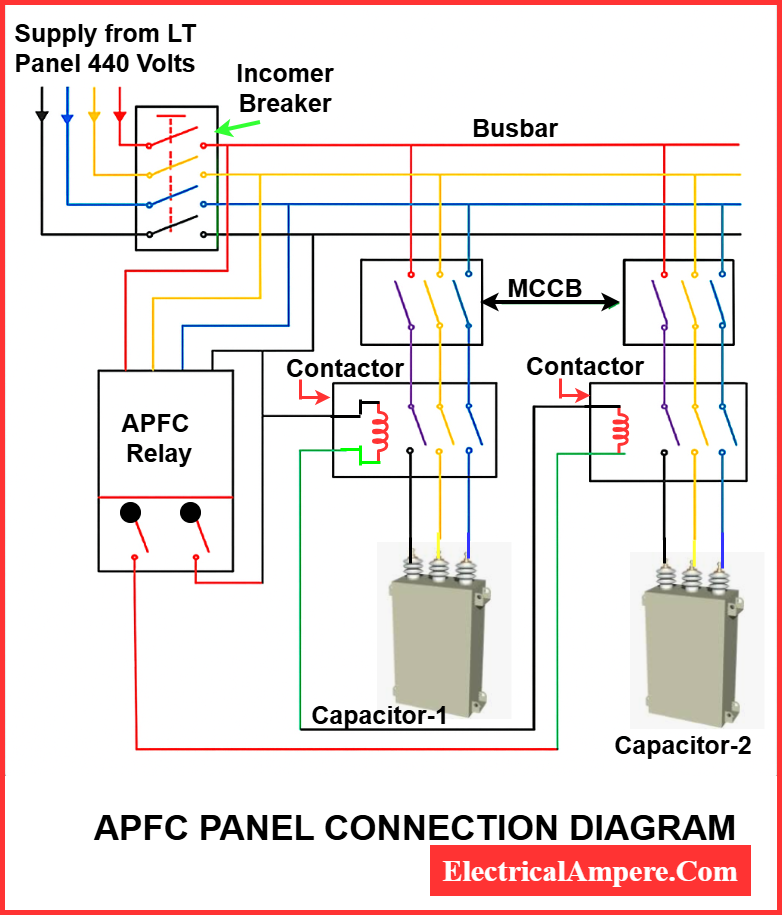

Wiring Diagram of APFC Panel

A simplified wiring diagram of an APFC panel is:

Explanation:

- The three-phase supply is connected to the load through the APFC panel.

- Current transformers (CTs) measure the load current and send signals to the controller.

- The controller decides which capacitor banks to switch ON or OFF based on the measured power factor.

- The capacitor banks provide reactive power to correct the power factor, maintaining it at the preset value automatically.

Advantages of APFC Panel

- Automatic Operation: No manual intervention required.

- Improves Power Factor: Reduces penalties and electricity bills.

- Reduces Losses: Lowers line losses in the system.

- Prolongs Equipment Life: Reduces strain on transformers and motors.

- Scalable: Capacitor banks can be added according to load requirement.

Applications of APFC Panel

- Industrial plants with induction motors and high reactive loads.

- Commercial buildings with lighting and HVAC systems.

- Factories where low power factor penalties are imposed by electricity boards.

- Any system with variable loads requiring automatic power factor correction.

Conclusion

An APFC panel is an essential device in modern electrical systems to maintain a healthy power factor, improve energy efficiency, and reduce electricity costs. With its automatic operation and protective features, it ensures safe, reliable, and efficient power management.

Related Articles: