Learn what a DTR structure is in electrical distribution systems. Explore its full form, materials list, cost estimation, and example setup, including transformer structure and DP structure details.

In the field of electrical power distribution, the term DTR structure frequently comes up, especially in rural and urban utility networks. This structure plays a vital role in ensuring the reliable delivery of electricity from substations to end users. Whether you’re an electrical engineer, site supervisor, or simply curious, understanding what a DTR structure is and how it’s constructed will enhance your knowledge of power systems.

What is a DTR Structure?

The full form of DTR in electrical engineering is Distribution Transformer. A DTR structure refers to the pole-mounted setup that supports and houses a distribution transformer. It is a crucial element of power distribution networks, used to step down high-voltage electricity from the sub-transmission level (typically 11 kV or 33 kV) to a safer, usable level (400/230 V) for domestic and commercial use.

DTR Full Form in Electrical

- DTR: Distribution Transformer

- It is also sometimes referred to as DP Structure, where DP stands for Double Pole, highlighting the two-pole arrangement commonly used in these installations.

Structure of Transformer (Pole-Mounted DTR)

The structure of a transformer installed on a pole comprises the following essential components:

- Transformer Unit: Typically oil-filled, with ratings such as 25 kVA, 63 kVA, 100 kVA, or 250 kVA depending on the load. The primary function of the transformer is to step down the voltage from 11 kV to 440 volts for three-phase supply or 230 volts for single-phase supply.

- Poles: PSC (Pre-Stressed Concrete) poles or RSJ (Rolled Steel Joist) poles, generally 8m to 9m long.

- Channels and Angles: Used to mount the transformer on poles, e.g., 100×50 mm channels.

- HG (Horn Gap) Fuses: Provide protection against surges and short circuits. The Horn Gap Fuses are used to protect the transformer from overloads and short-circuit currents. In the event of a fault or overload on the 11 kV HT line, the horn gap fuse disconnects the circuit, thereby safeguarding the transformer from potential damage.”

- DO (Drop Out) Fuses: Isolate the transformer in case of faults.

- Lighting Arrestors (LAs): Protect the transformer from lightning surges. 11 kV class lightning arresters are used and are installed at the top of the DP structure, as shown in the image above. Their primary function is to protect the transformer from lightning surges. When lightning strikes the structure, the arresters safely divert the surge current to the ground, thereby preventing damage to the transformer. A total of three lightning arresters are installed for effective protection

- Earthing System: Includes earth pipes and earth wires for safety and surge protection. A total of three earthing will be provided for the DP structure. One earthing will be connected to the lightning arrester, another to the transformer neutral, and the third to the metallic components of the DP structure. All three earthing will be interconnected to ensure a common grounding system.

- Stay Sets: Provide mechanical support to poles.

- Insulators: Pin and disc types for supporting and insulating conductors.

- AB Switch (Air Break Switch): AB switch is also known as Gang Operated Switch (GOS). The purpose of the gang operating switch is to isolate the circuit during maintenance or repair work. It allows all lines to be disconnected simultaneously with a single operation, ensuring safety and ease of operation.

- Cable and Conductor: XLPE insulated cable (for LV side) and ACSR conductor (for HT side).

- LT Metering Box: The LT metering box contains meters, relays, and other protective devices. It is typically installed at the base of the structure for easy access and monitoring.”

Materials Required for a Typical 25 kVA DTR Structure

Here’s a standard material list for a 25 kVA DTR structure:

| Item | Description | Quantity |

|---|---|---|

| 1 | 9m PSC Poles or RS Joists | 2 |

| 2 | 25 kVA, 11/0.433 kV Transformer | 1 |

| 3 | Channel Iron 100×50 mm (1.5 m) | 2 |

| 4 | AB Switch 11 kV | 1 set |

| 5 | DO Fuse Set 11 kV | 1 set |

| 6 | Lighting Arrestors (LAs) | 3 |

| 7 | HG Fuses | 3 |

| 8 | Stay Sets | 2 |

| 9 | GI Pipe for Earthing (2.5 m) | 2 |

| 10 | Earthing Wire (GI Strip 25×3 mm) | As required |

| 11 | ACSR Conductor 6/1 | As required |

| 12 | Pin Insulators and Disc Insulators | As required |

| 13 | Bolts, Nuts, Clamps, etc. | As required |

| 14 | Danger Board and Number Plate | 1 each |

Estimation of a DTR Structure

To estimate the cost of a DTR structure, the following parameters must be considered:

1. Material Cost

Includes cost of the transformer, poles, AB switch, fuses, channels, conductors, and other hardware.

2. Labour Cost

Skilled and unskilled labor charges for erecting poles, installing the transformer, stringing conductors, and making connections.

3. Transportation

Cost of transporting materials to the installation site.

4. Contingency and Overheads

Usually 10%–15% of total cost to cover unforeseen expenses and administrative overheads.

Example:

For a 25 kVA DTR structure, total estimation (approximate):

- Material: ₹1,25,000

- Labour: ₹15,000

- Transport: ₹10,000

- Overheads: ₹15,000

Total Estimate: ₹1,65,000 (INR)

Note: Prices vary based on region, suppliers, and specifications.

Example DTR Structure Design Layout

Scenario: Installing a 25 kVA transformer in a rural feeder

- Poles: 2 x 9m PSC poles

- Transformer: Mounted on 2 parallel channels fixed on poles

- Protection Devices: DO fuse and LA on HT side

- Cable Connection: ACSR conductor on HT side, XLPE cable on LV side

- Earthing: 2 earth pits, GI earthing wires connected to LA and transformer tank

- AB Switch: Installed for manual isolation during maintenance

This setup ensures safe, reliable power distribution with sufficient fault protection.

Applications of DTR Structure

- Rural and urban power distribution

- Agricultural connections (for irrigation)

- Street lighting transformers

- Residential clusters and colonies

- Temporary power supply in construction sites

Q. Select a Suitable Transformer for an Industrial Area

Given Data:

- Available voltage (Primary): 11 kV

- Required voltage (Secondary): 440/230 V

- Lighting load: 10 kW

- Industrial load: 50 kW at 0.8 power factor

- Demand factor: 0.7

- Diversity factor: 1.46

- Allowance for future expansion: 20%

Step 1: Calculate Total Connected Load

Total connected load = Lighting load + Industrial load (in kVA)

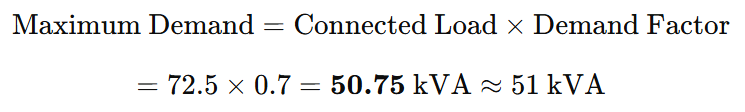

Step 2: Calculate Maximum Demand

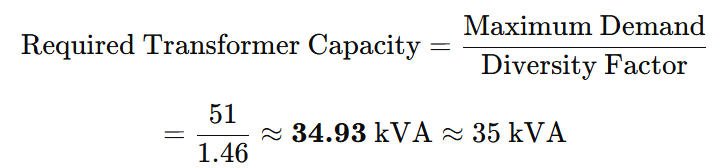

Step 3: Determine Required Transformer Capacity

Step 4: Add Allowance for Future Expansion (20%)

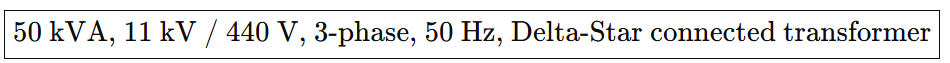

Step 5: Select the Nearest Available Standard Transformer

Since 42 kVA transformers are not a standard rating, the nearest higher standard size is:

Conclusion

The DTR structure is the backbone of power distribution systems, especially in areas where underground networks are impractical. A clear understanding of the full form of DTR, its components, materials required, and cost estimation can greatly assist engineers and contractors in planning efficient electrical distribution networks. Whether you’re referring to it as a DP structure or analyzing the structure of transformer in a power distribution setup, DTR structures remain essential for a dependable and safe electricity supply.

Read Next: